Patents

Literature

81results about How to "Improve installation and maintenance efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

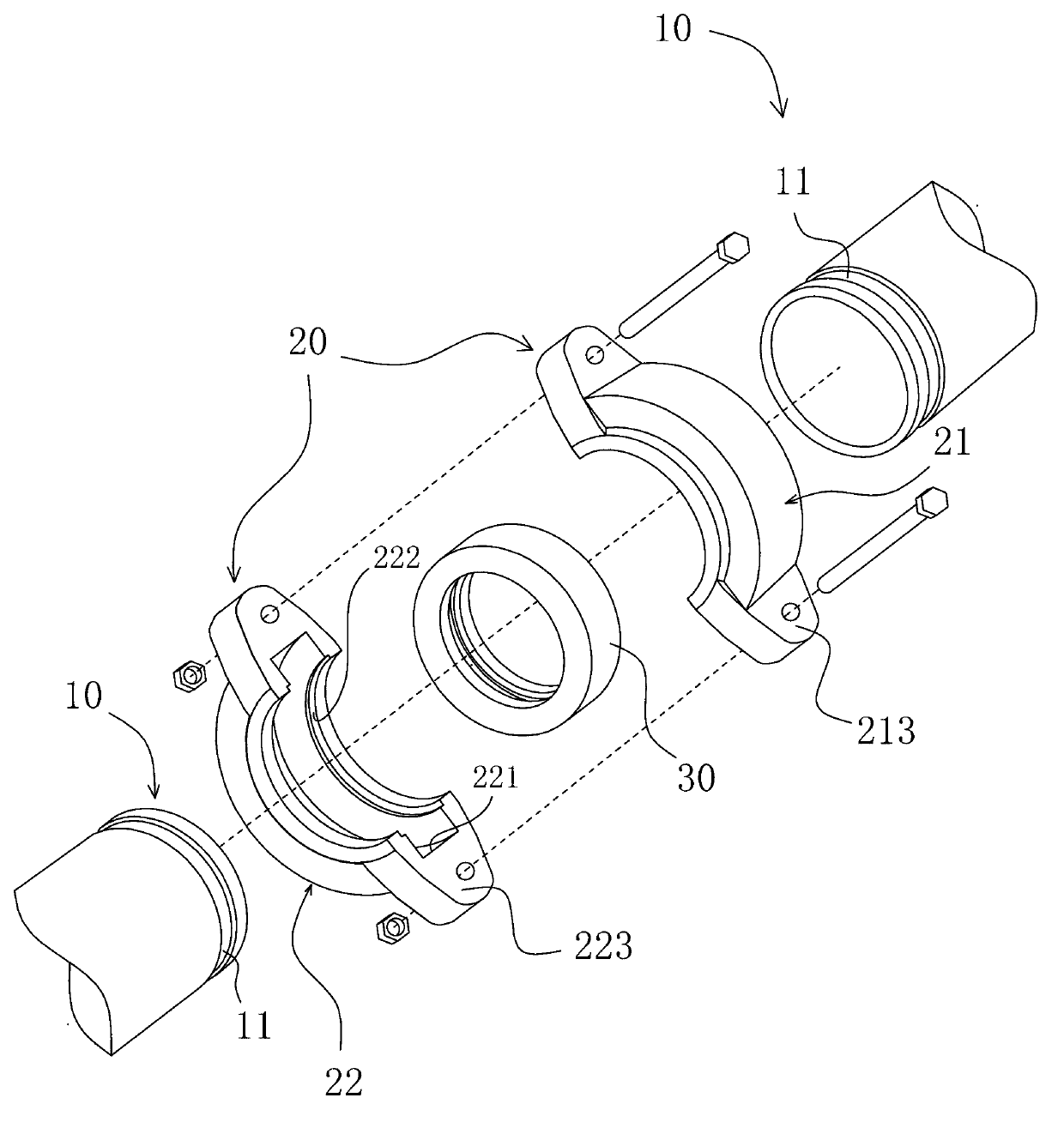

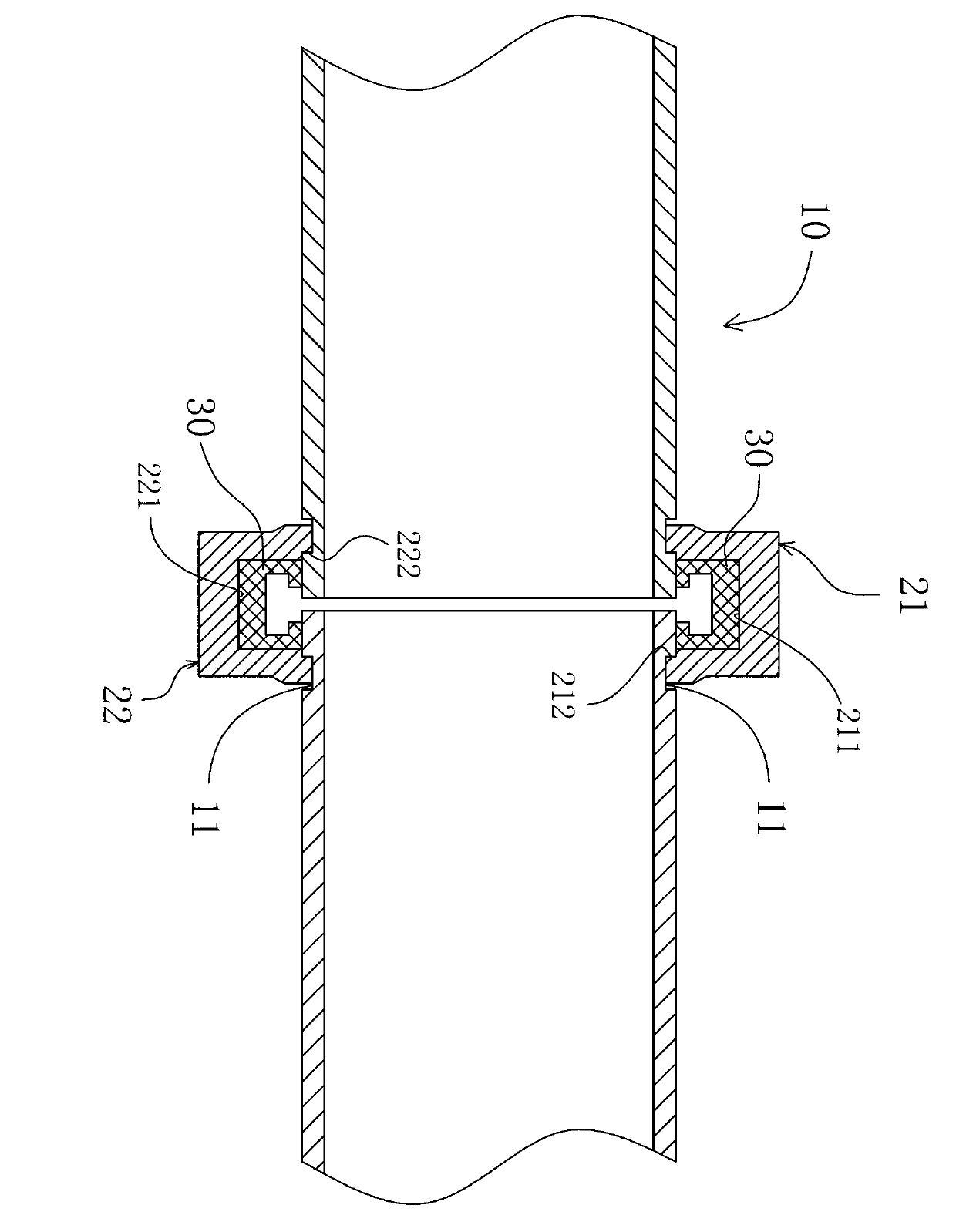

Installation method of firefighting pipe fitting

ActiveCN102966808AEasy to installImprove installation and maintenance efficiencySleeve/socket jointsSteel tubeFirefighting

The invention discloses an installation method of a firefighting pipe fitting. The method comprises the following steps of: a, cutting multiple sections of steel pipes of the same diameter on a construction field according to a designed length; b, processing an inwardly-concave annular neck surrounding a circumferential surface on the outer circumferential surfaces of end faces close to the two ends of each section of cut steel pipe respectively; c, spraying anti-rusting paint onto the outer surface of each section of steel pipe on which the neck is processed, and spraying finish paint to form multiple sections of firefighting pipes which are consistent with the designed length; and d, connecting the multiple sections of firefighting pipes into an indoor firefighting pipeline by using a plurality of clamping bands, and sealing the joints of the firefighting pipes and the clamping bands by using sealing pieces. The installation method has the characteristics of convenience and rapidness in processing and installing, easiness in maintaining, high installation efficiency, low cost and the like.

Owner:SHENZHEN GUANGAN FIRE FIGHTING & DECORATION ENG

Pipeline structure of air conditioner evaporator

ActiveCN104566923AQuick installationReduce volumeEvaporators/condensersSpace heating and ventilation detailsEvaporatorEngineering

The invention relates to the field of air conditioners, in particular to a pipeline structure of an air conditioner evaporator. The pipeline structure comprises the evaporator, wherein a liquid inlet pipe joint and an air collecting pipe joint are arranged at the same side of the evaporator, a left liquid inlet opening passage and a left air collecting opening passage are arranged at the left end of a fin, a right liquid inlet opening passage and a right air collecting opening passage are arranged at the right end of the fin, the left liquid inlet opening passage is communicated with the right liquid inlet opening passage, the left air collecting opening passage is communicated with the right air collecting opening passage, and the liquid inlet pipe joint and the air collecting pipe joint are respectively communicated with a liquid inlet pipe joint and an air collecting pipe joint at the corresponding side through a liquid inlet tee pipe and an air collecting tee pipe. The pipeline structure has the advantages that when an air conditioner is installed, a liquid inlet passage and an air collecting passage at the left end or the right end of the evaporator can be connected according to the actual requirements, the reserving of a pipe through passage at the back side of the air conditioner is not needed, the usage amount of pipeline material is saved, and the whole size and thickness of the air conditioner are improved; in addition, the air conditioner can freely realize the quick installation at the left side or the right side, and the installation and maintenance efficiency of after-sales persons is improved.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

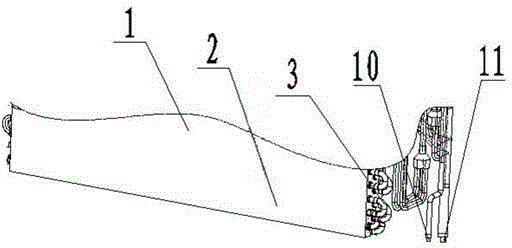

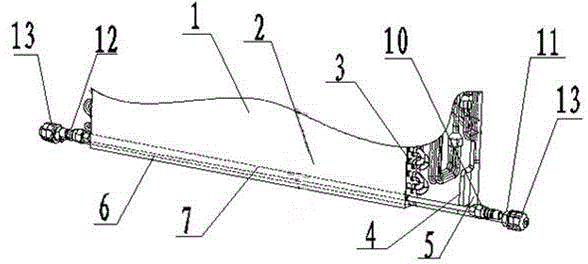

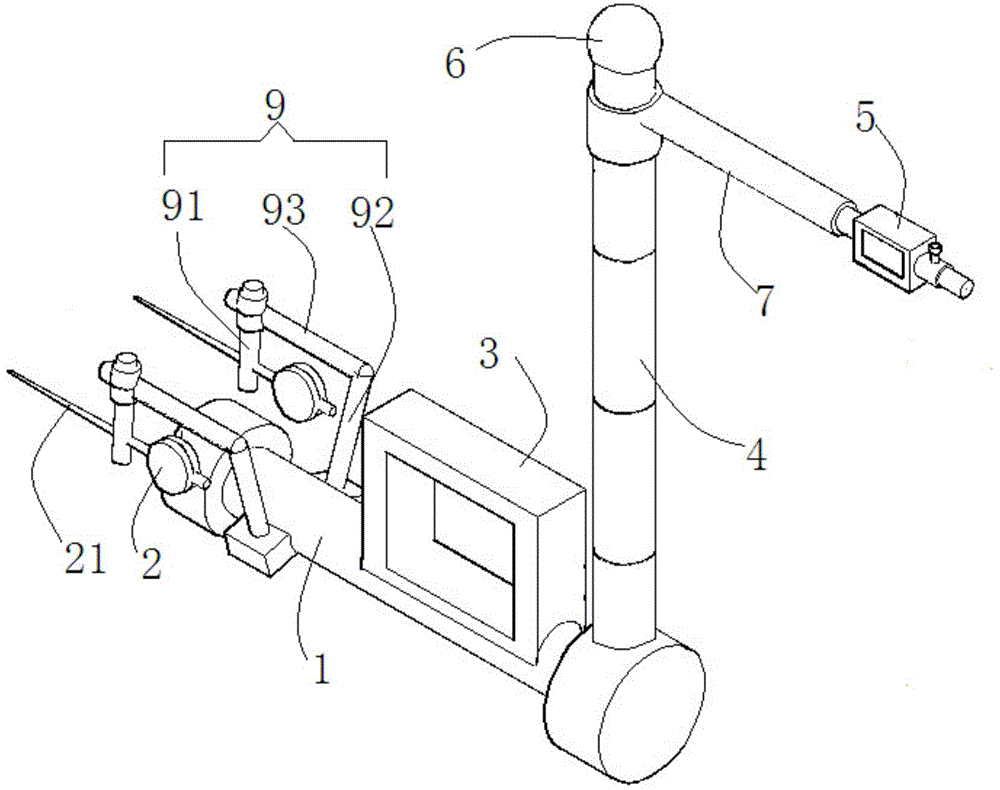

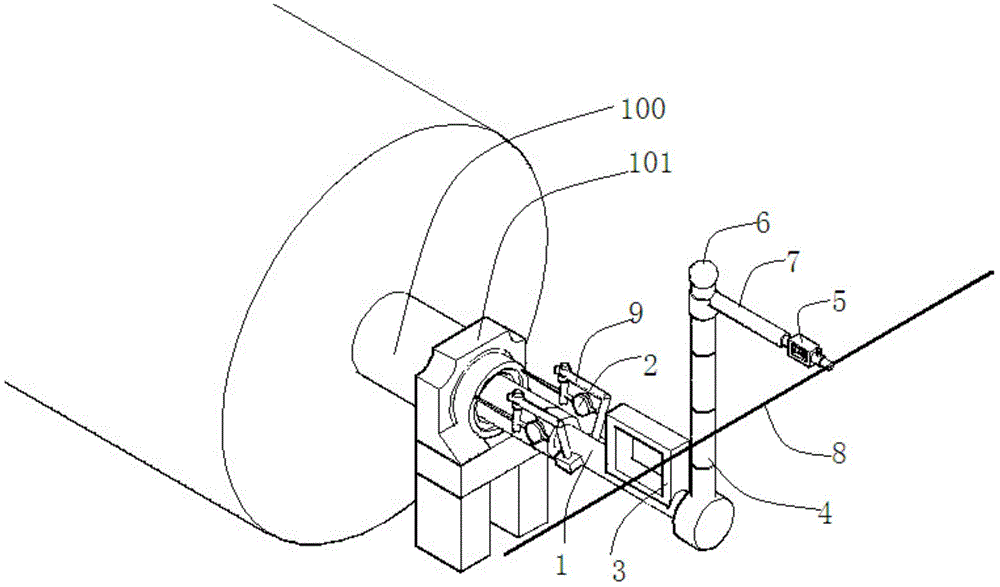

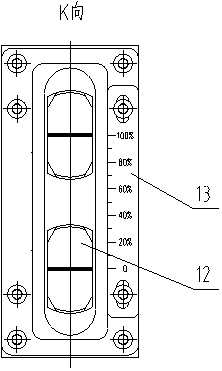

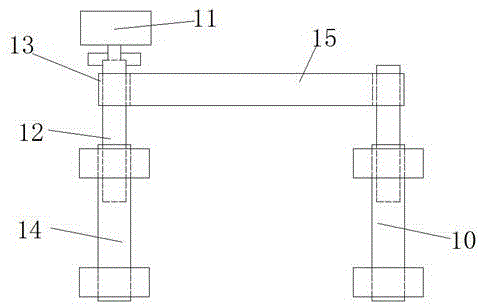

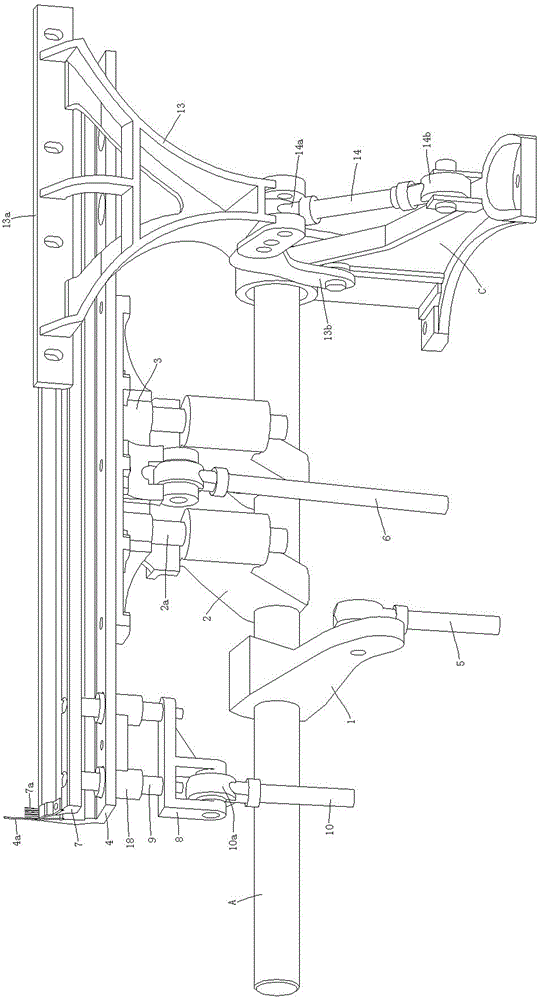

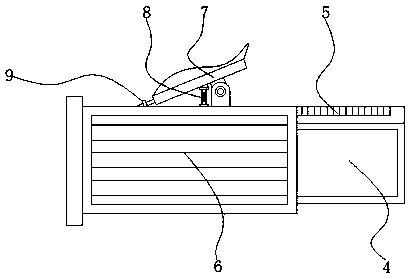

Light-emitting type digital display furnace roller precision measurement device

ActiveCN106323142AImprove online detection efficiencyReduce labor costsAngles/taper measurementsIncline measurementMeasurement deviceEngineering

A light-emitting type digital display furnace roller precision measurement device provided by the present invention comprises an examination shaft, dial indicators, a frame-type gradienter, a connection swinging rod and a digital display dial indicator. The two dial indicators are connected with the examination shaft movably, the center lines of the measuring rods of the dial indicators are parallel with the shaft center line of the examination shaft, and the frame type gradienter is arranged on the outer circumferential wall of the examination shaft. One end of the examination shaft is connected with a roller shaft of a furnace roller detachably and coaxially, and the other end is connected with the lower end of the connection swinging rod vertically. A contact type indicating lamp is arranged on the upper end face of the connection swinging rod, the upper end of the connection swinging rod is connected with a cross bar connected with the digital display dial indicator, and a switch circuit of the contact type indicating lamp is connected with the digital display dial indicator and a reference steel wire separately. The light-emitting type digital display furnace roller precision measurement device can measure the efficiency and the precision, enables the labor intensity of workers to be reduced, can eliminate the potential safety hazards, and can effectively relieve the problem that there is not existed enough time to overhaul a travelling crane annually.

Owner:MCC BAOSTEEL TECH SERVICE

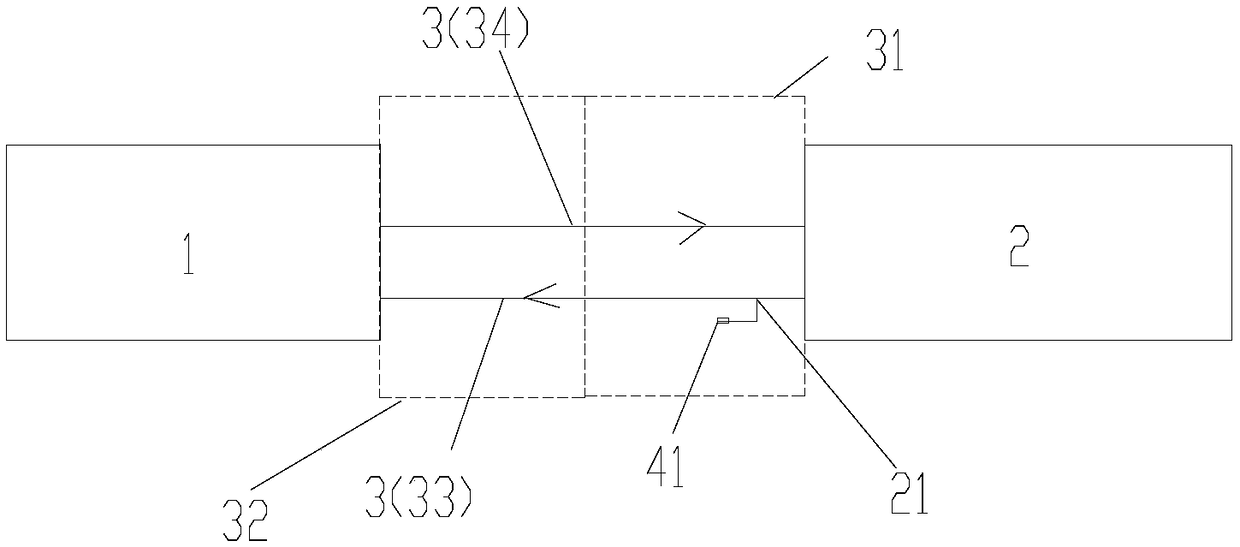

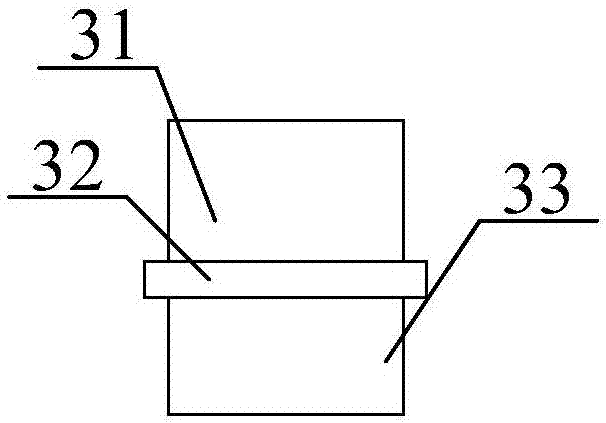

Air conditioner

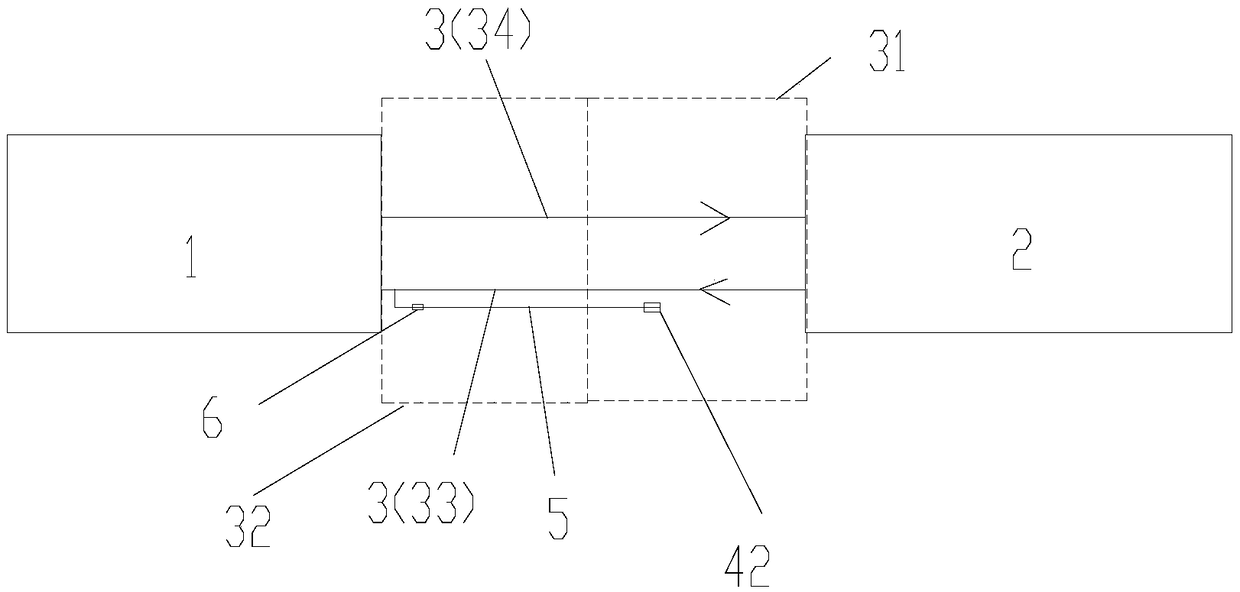

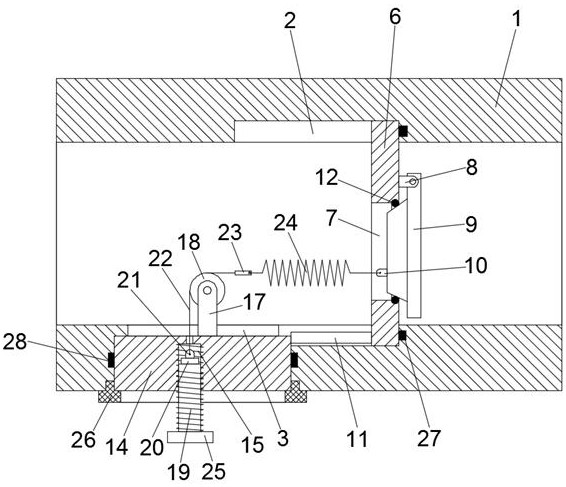

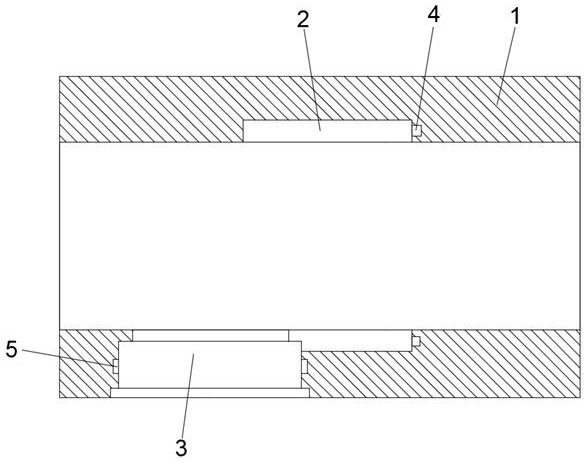

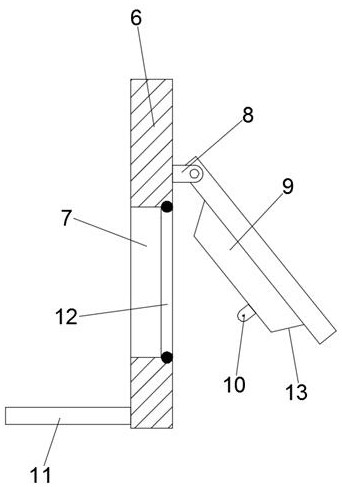

PendingCN108800686AEasy installation and maintenanceImprove installation and maintenance efficiencyRefrigeration componentsAir conditioning systemsSafety coefficientEngineering

The invention provides an air conditioner. The air conditioner comprises an outdoor unit (1), an indoor unit (2) and a refrigerant pipeline (3) connected between the outdoor unit (1) and the indoor unit (2). The refrigerant pipeline (3) comprises a first pipeline part (31) located in the indoor position and a second pipeline part (32) located on the outdoor position, and a first refrigerant filling nozzle (41) capable of carrying out vacuumizing or refrigerant filling on the refrigerant pipeline (3) is arranged on the first pipeline part (31); and / or, a connecting pipe (5) is further connectedto the second pipeline part (32), one end of the connecting pipe (5) can communicate with the interior of the refrigerant pipeline (3), and the other end of the connecting pipe (5) extends into the indoor position and is connected with a second refrigerant filling nozzle (42) capable of carrying out vacuumizing or refrigerant filling on the refrigerant pipeline (3). By means of the air conditioner, vacuumizing and refrigerant filling can be carried out on an air conditioner system on the indoor side, mounting and maintenance is simpler and more convenient, and the safety coefficient is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Optical fiber location judgment method

ActiveCN104038277AImprove installation and maintenance efficiencyAvoid human errorTransmission monitoring/testing/fault-measurement systemsUltrasound attenuationOptical power

The invention relates to an optical fiber location judgment method. The optical fiber location judgment method includes the following steps that an optical fiber inquiry software is installed on a mobile terminal, and the optical fiber inquiry software is connected with a background inquiry system; the optical fiber inquiry software inputs an inquiry instruction, and the inquiry instruction includes information of an optical fiber to be inquired; the optical fiber to be inquired is bent, and certain attenuation occurs at a bent section; the background inquiry system real-timely scans and compares user side receiving optical power values of all ports which share the same passive optical network (PON) port with the optical fiber to be inquired, detects whether the optical power value of each port changes or not within a relative time period and sends relevant inquiry information to the mobile terminal, and optical fiber location judgment can be achieved. The optical fiber location judgment method has the advantages that various communication optical fibers can be real-timely monitored, routes and relevant attributes of the optical fibers are judged, the mounting and maintaining efficiency is greatly increased, human errors are avoided, and communication safety is guaranteed.

Owner:CHANGZHOU LENCITY INFORMATION TECH

Pressure relief valve easy to install

ActiveCN112228604AEasy to installSimple structureEqualizing valvesSafety valvesEngineeringScrew thread

The invention discloses a pressure relief valve easy to install. The pressure relief valve comprises a valve body, a partition plate and a mounting block, and a sliding groove is formed in the inner wall of the valve body; the partition plate is clamped in the sliding groove slidably, and a stepped mounting hole is formed in one side of the valve body; a pressure relief opening is formed in the partition plate, and the end face of one side of the partition plate is rotatably connected with a sealing cover; a threaded hole is formed in the mounting block, and a guide wheel is rotatably mountedon the end face facing the interior of the valve body; a locking snap ring is mounted between the mounting block and the mounting hole; a stud is arranged in the threaded hole in a threaded sleeving mode, a stay rope is connected with the stud; and the stay rope is rotatably wound around the guide wheel, and a spring is connected between the tail end of the stay rope and the sealing cover. The pressure relief valve east to install is simple in structure, and the sliding groove and the mounting hole are formed in the valve body, so that rapid disassembly and assembly of the partition plate andthe mounting block are achieved; internal components can be replaced, maintained and cleaned without disassembly of the whole valve body, and the disassembly and assembly time is saved; and the stud is rotated to drive the spring to stretch for adjustment, so that the pressure relief threshold is changed, and the adjustment is convenient and efficient.

Owner:山东蓬能机械科技有限公司

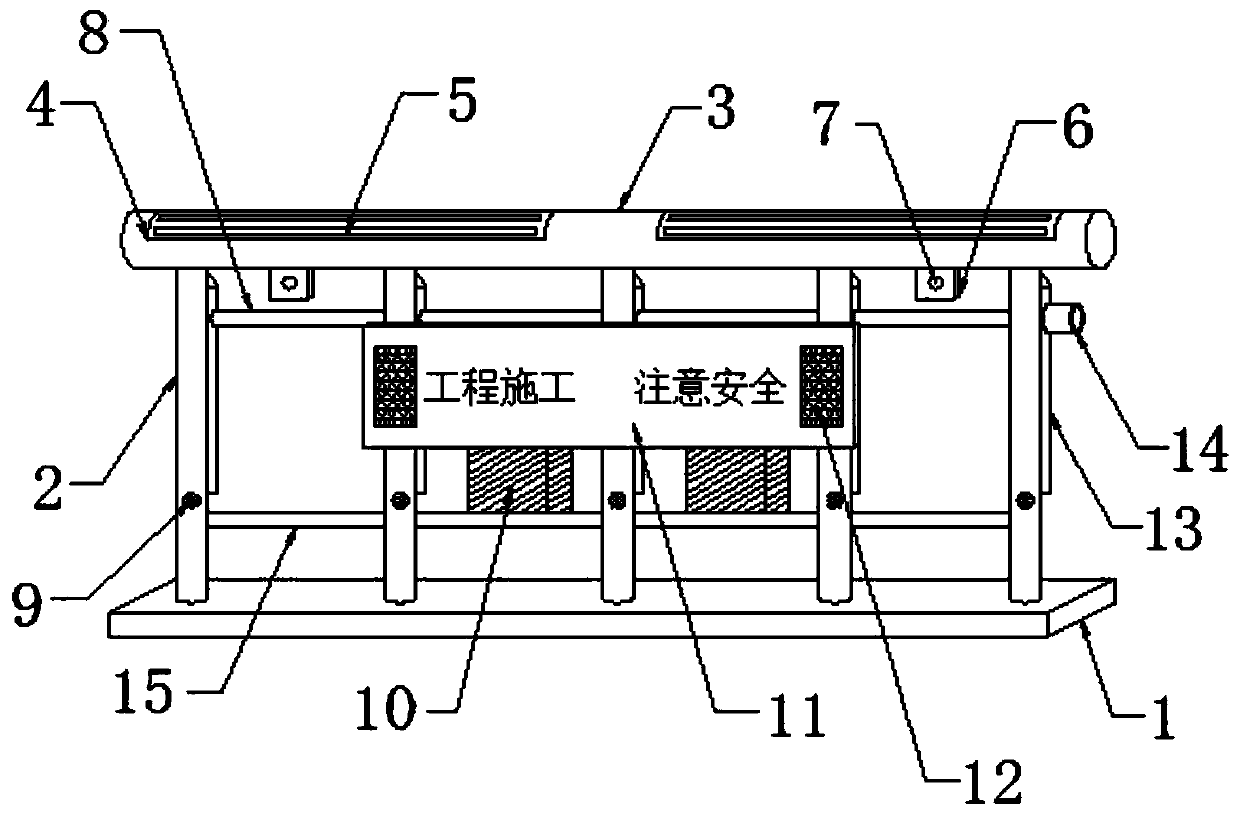

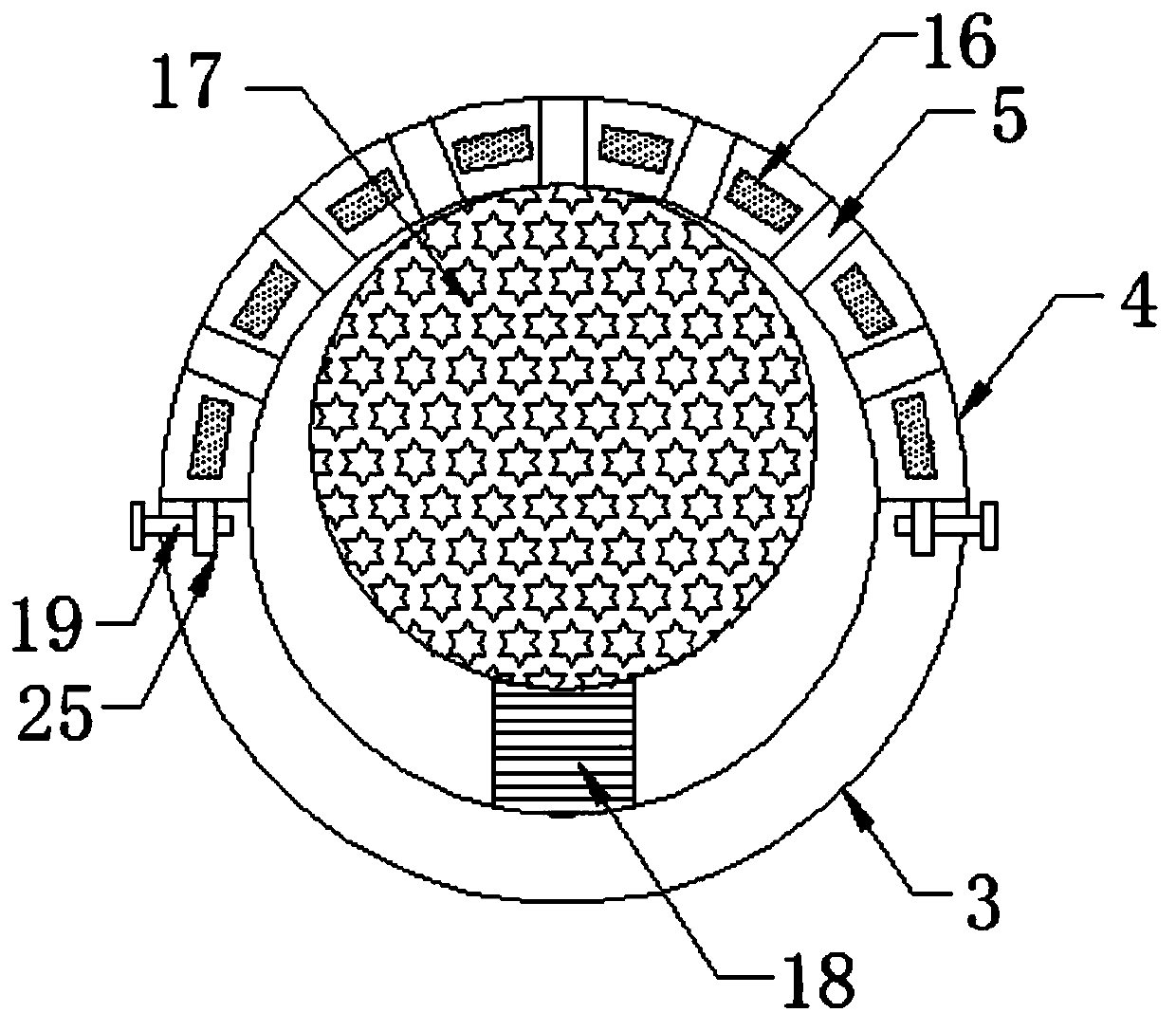

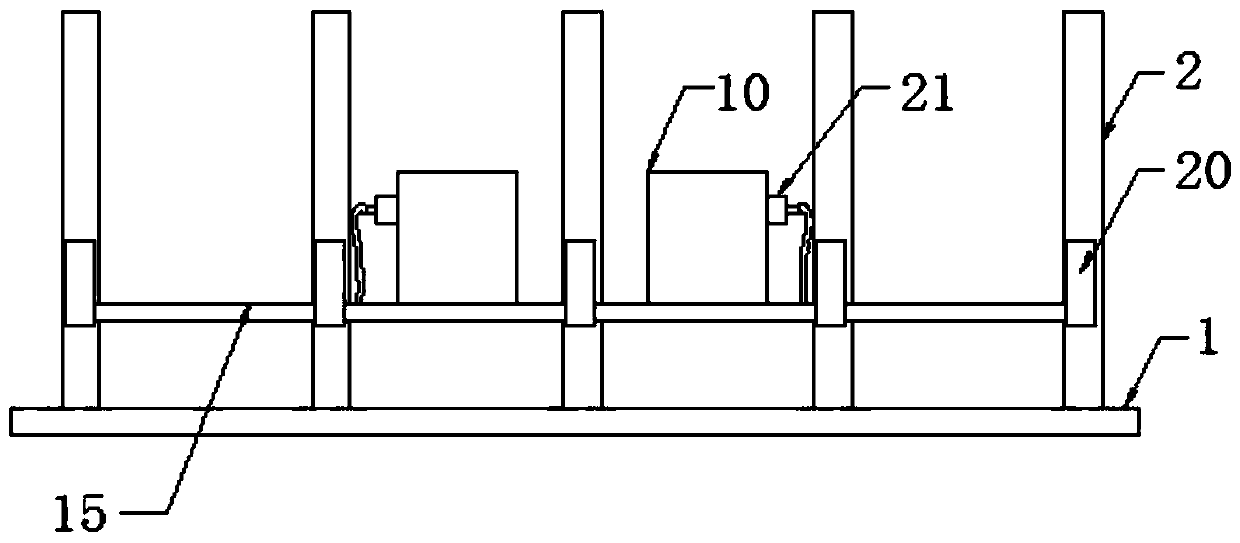

Guardrail capable of being spliced and being easy in maintenance for highway engineering

ActiveCN110593167AEasy maintenanceEasy to transportRoad cleaningTraffic signalsWater storageVertical bar

The invention discloses a guardrail capable of being spliced and being easy in maintenance for highway engineering. The guardrail comprises a bottom plate, wherein the upper side of the bottom plate is provided with a cross bar; the top end of the bottom plate is in threaded connection with a plurality of vertical rods at equal intervals; the top ends of the plurality of vertical bars are independently clamped and connected with the bottom end of the cross bar; the front sides of three vertical bars are provided with a notice board; two sides of the front side of the prompt board are independently fixedly embedded with a solar cell panel; two sides of the back side of the prompt board are independently fixedly connected with a water storage tank; a water inlet is dug on one side of the topend of each water storage tank; and two sides of the bottom end of the cross bar are independently fixedly connected with a fixing plate. The guardrail capable of being spliced and being easy in maintenance for highway engineering is provided with the cross bar, the plurality of vertical bars and a base, can be quickly assembled, is convenient in maintenance and transportation and greatly improves installation and maintenance efficiency. A plurality of cylindrical water storage cavities and human body proximity switches are arranged and are cooperated with two water storage tanks, a water suction pump and a first atomization shower nozzle, so that the approaching of people can be identified, and water sprays are automatically sprayed to remind pedestrians and prevent pedestrians from going through the guardrail at will.

Owner:付万菊

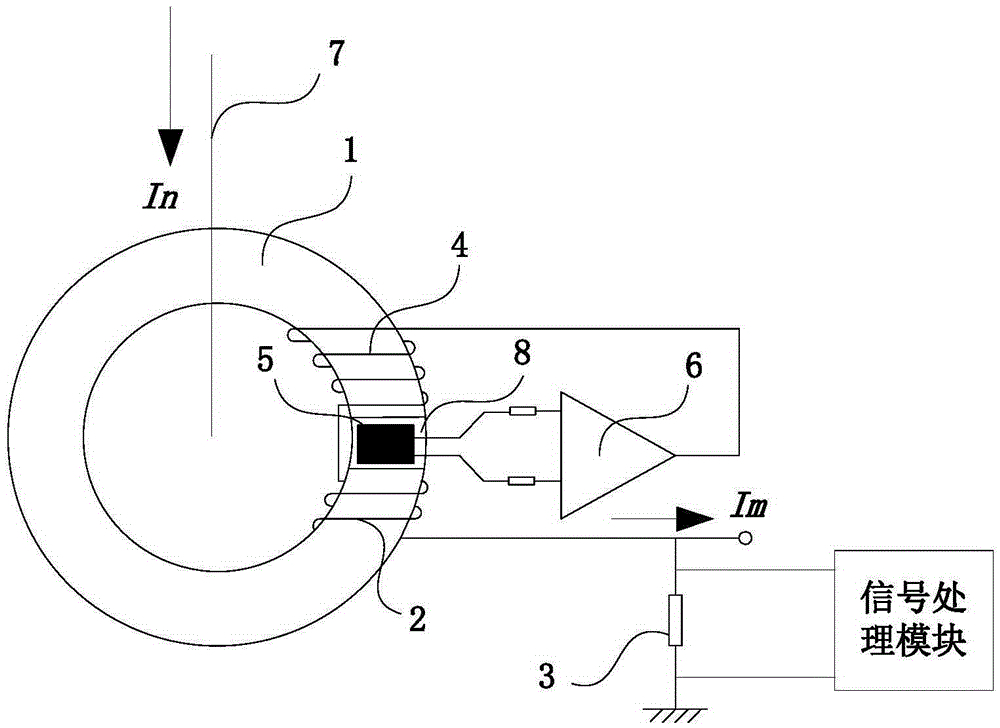

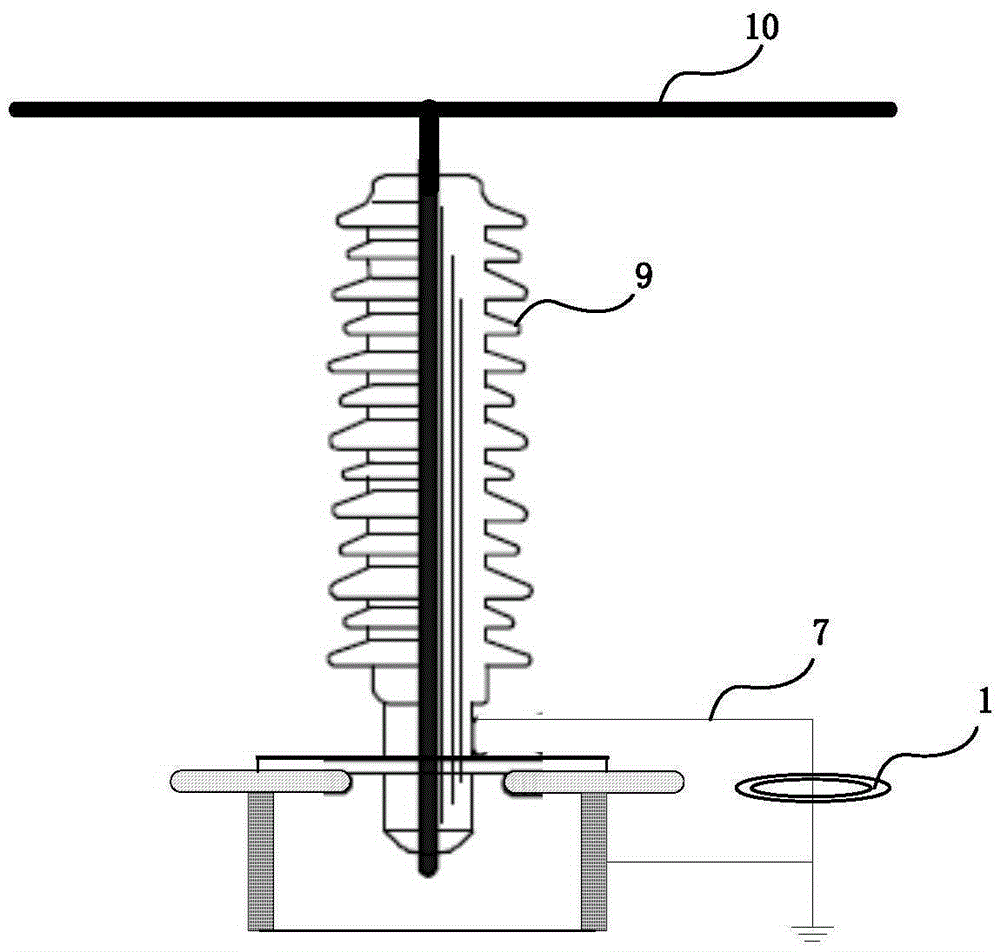

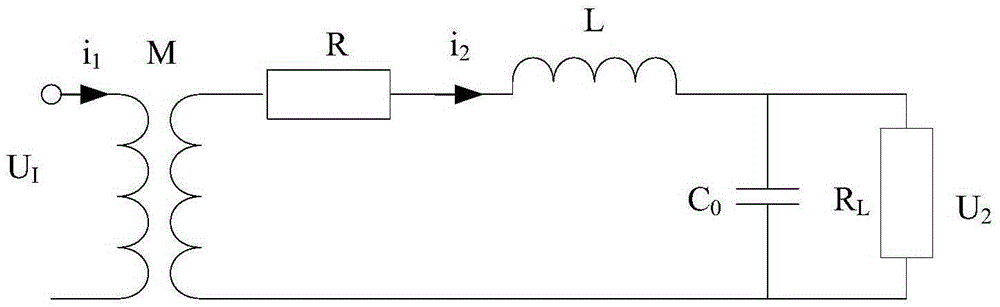

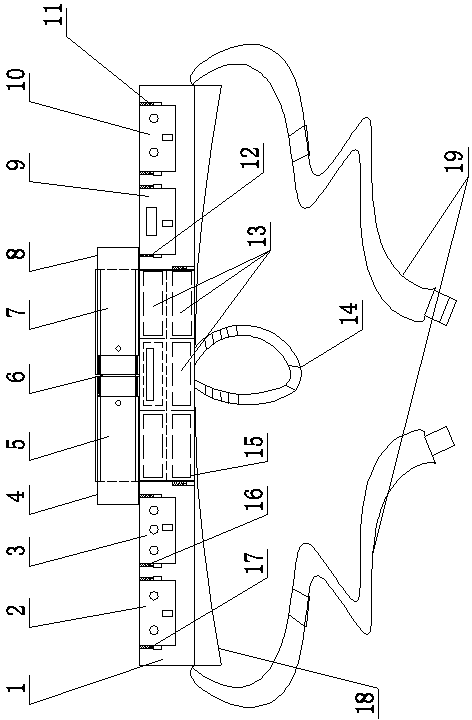

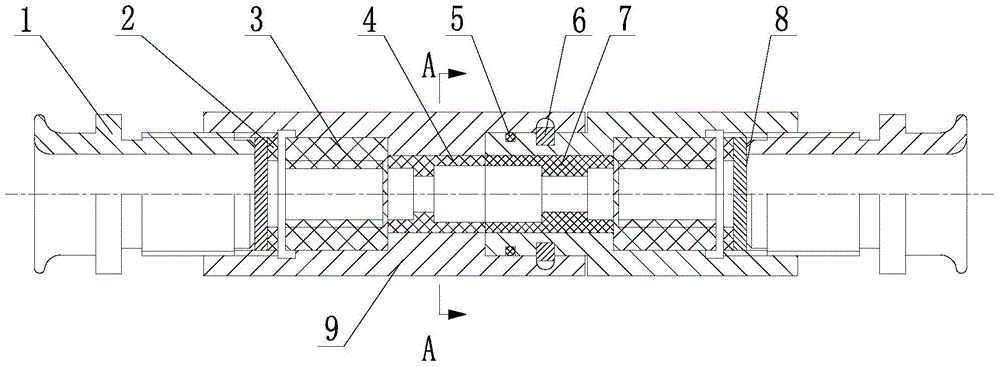

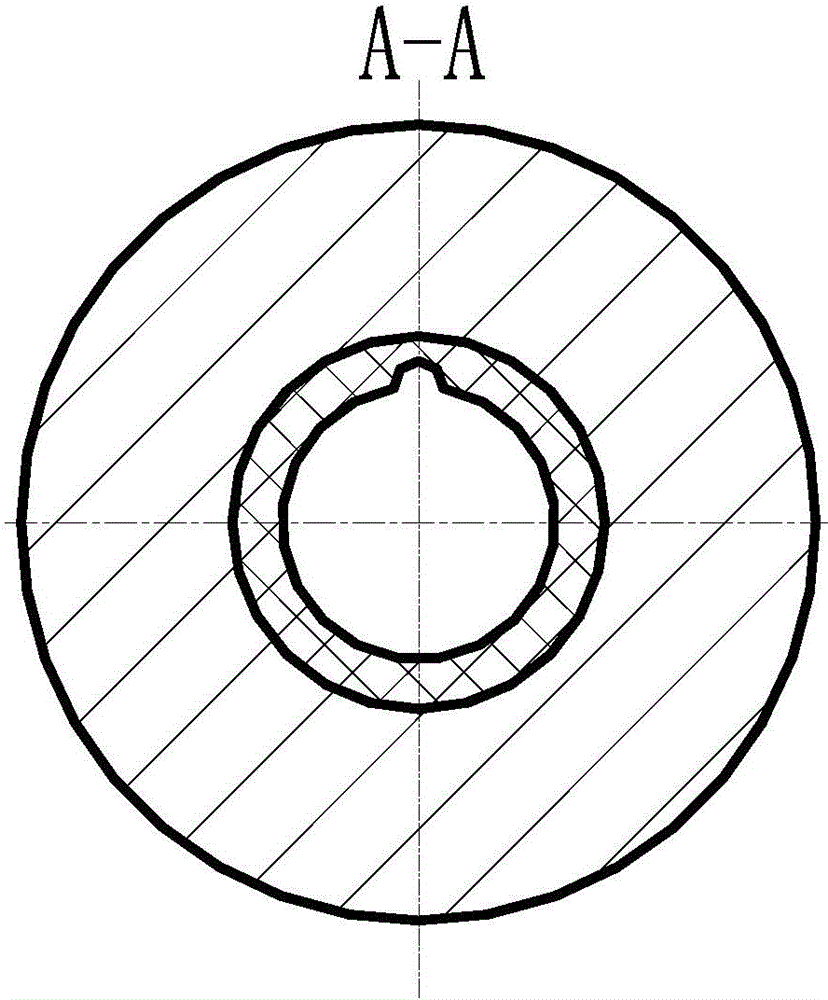

A Transformer Online Monitoring Sensor

InactiveCN103576030BAccurate fault signalImprove safety and reliabilityElectrical testingComputer moduleEngineering

The invention relates to the technical field of electrical equipment on-line monitoring, and discloses a transformer on-line monitoring sensor. The transformer on-line monitoring sensor comprises an annular core, a secondary side coil, a measuring resistor, a compensating coil, a magnetic-flux measurement sensor, a compensating circuit and a signal processing module, wherein a transformer bushing end screen outgoing line perpendicularly penetrates through the center of the annular core, the annular core is provided with a groove used for containing the magnetic-flux measurement sensor, the input end of the secondary side coil is connected with the output end of the compensating coil, the measuring resistor is arranged between the output end of the secondary side coil and the ground in a parallel connection mode, the magnetic-flux measurement sensor is placed into the groove, and is connected with the compensating circuit, the compensating circuit is connected with the input end of the compensating coil, and the signal processing module is arranged between the two ends of the measuring resistor in a parallel connection mode. The transformer on-line monitoring sensor can obtain accurate fault signals through measurement, and carry out on-line monitoring on various fault signals at the same time; due to the fact that primary wiring does not need to be modified, and safety and reliability of on-line monitoring and efficiency of equipment installation and maintenance are improved.

Owner:STATE GRID CORP OF CHINA +3

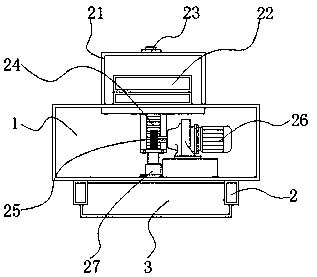

Automatic dumping garbage can based on motor driving

The invention discloses an automatic dumping garbage can based on motor driving, and relates to the technical fields of environmental sanitation and environmental protection. The automatic dumping garbage can comprises a supporting device, a box and a chuck; the box is fixedly hung on the supporting device and rotatably dumps garbage through motor driving, and a circular clamping base is fixed to the end of a supporting column; the clamping base is connected with the box in the mode of cooperating with the chuck; and a circular groove is in interference fit with a transmission rod. According to the automatic dumping garbage can based on motor driving, a servo motor is arranged to control the box to rotate, a sanitation worker does not need to manually dump garbage, automatic garbage dumping is achieved, cleaning work of the sanitation worker is convenient, and the advantages of being simple in structure, convenient to use and practical are achieved; by arranging the supporting device, the box is supported, vertical rotation of the box is achieved, therefore, the assembling mode among structures is reduced, structural materials are reduced, the production cost is reduced, and the installing and maintaining efficiency is improved.

Owner:合肥巨步机械科技有限公司

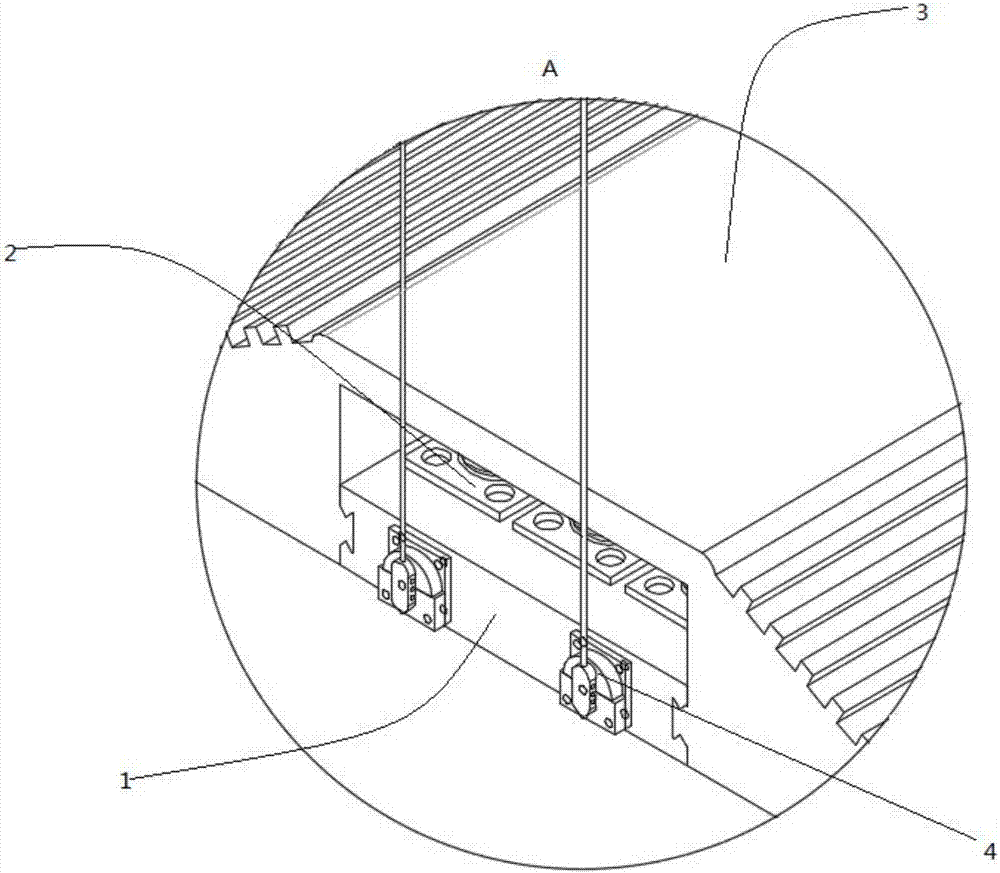

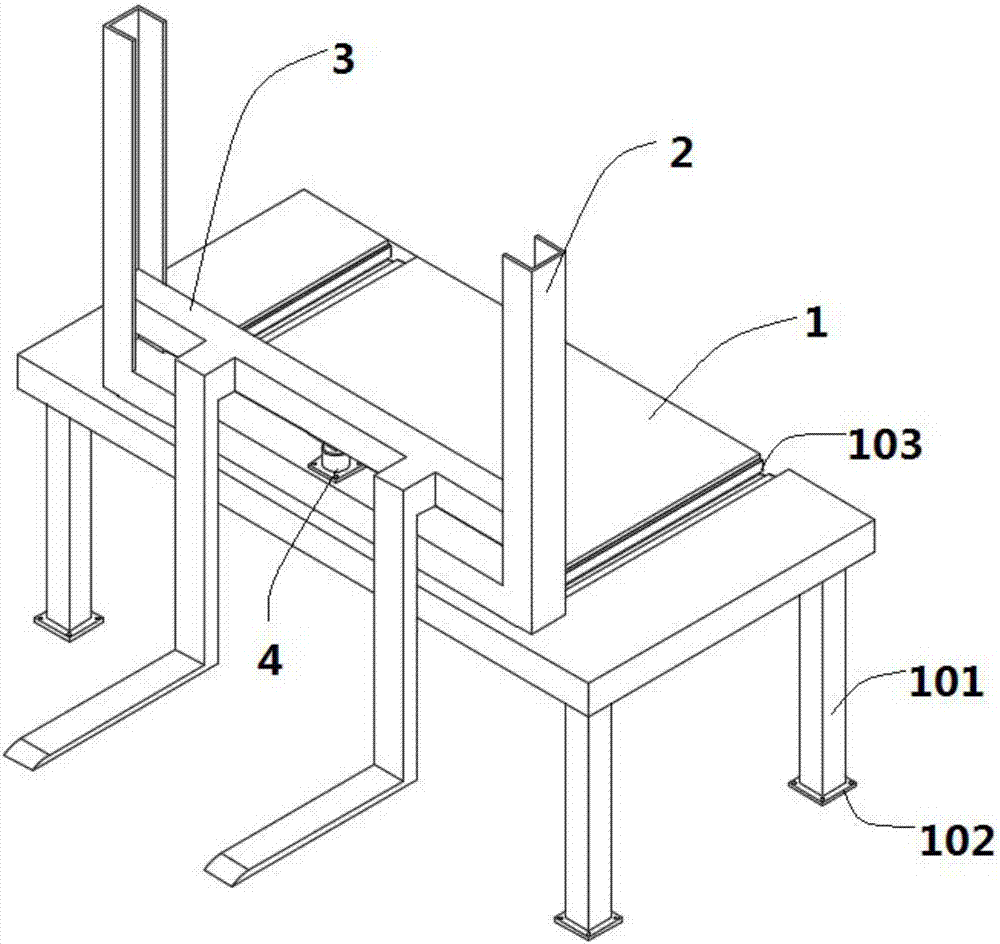

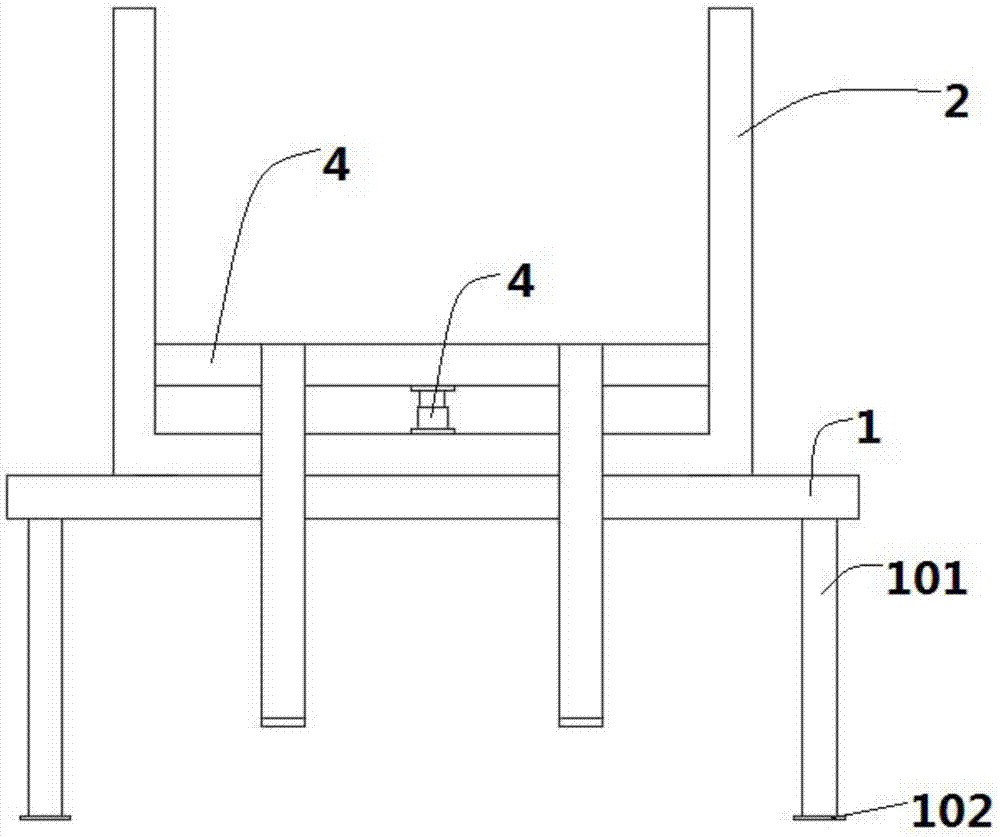

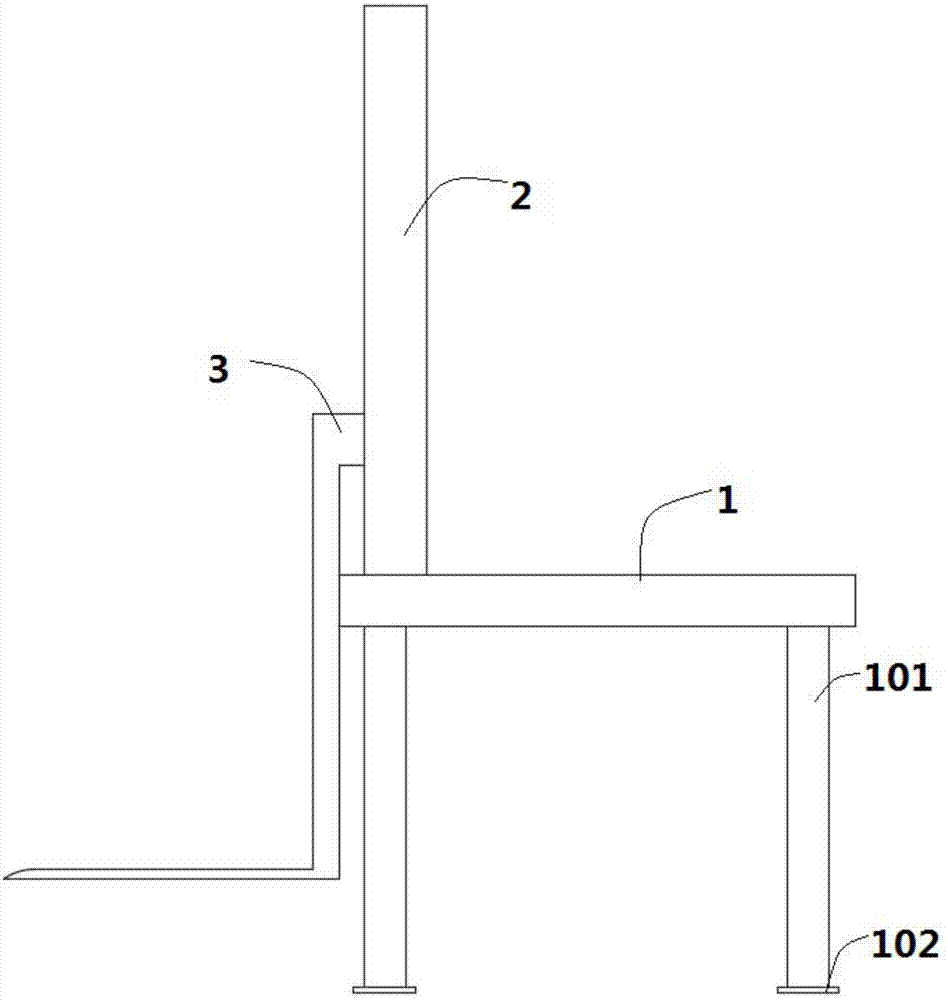

Pedestal based on four-column hoist

The invention discloses a base based on a four-post lift. It includes a base, a first sliding device, a second sliding device and an adsorption device; the surface of the base is provided with several studs; a surface of the base is provided with a first chute; the first sliding device is connected with the base; The slot slides in the direction, and the second sliding device is connected with the first sliding device; the second sliding device slides up and down along the second chute; the second sliding device is connected with the adsorption device; the adsorption device is provided with an electromagnetic suction cup. By setting the base to fix the lift support device, the invention disperses the torsional force of the column, does not have high requirements on the foundation, has wide applicability and is convenient to use. By arranging the chute to make the sliding device slide, the assembly method between the structures is reduced, the structural material is reduced, the production cost is reduced, and the installation and maintenance efficiency is improved. By setting the electromagnetic sucker to fix the lifting device of the lift, the lifting device can be prevented from shaking during the lifting process, which is safe and reliable, and protects the maintenance personnel.

Owner:HEFEI YIHANG MACHINERY TECH CO LTD

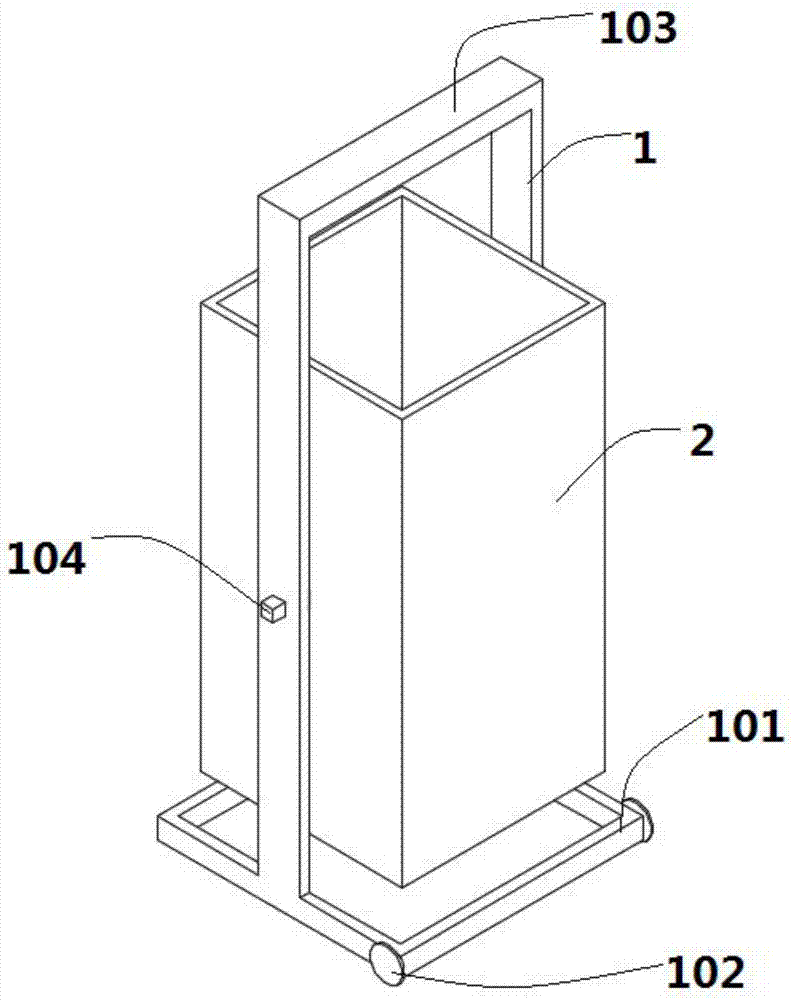

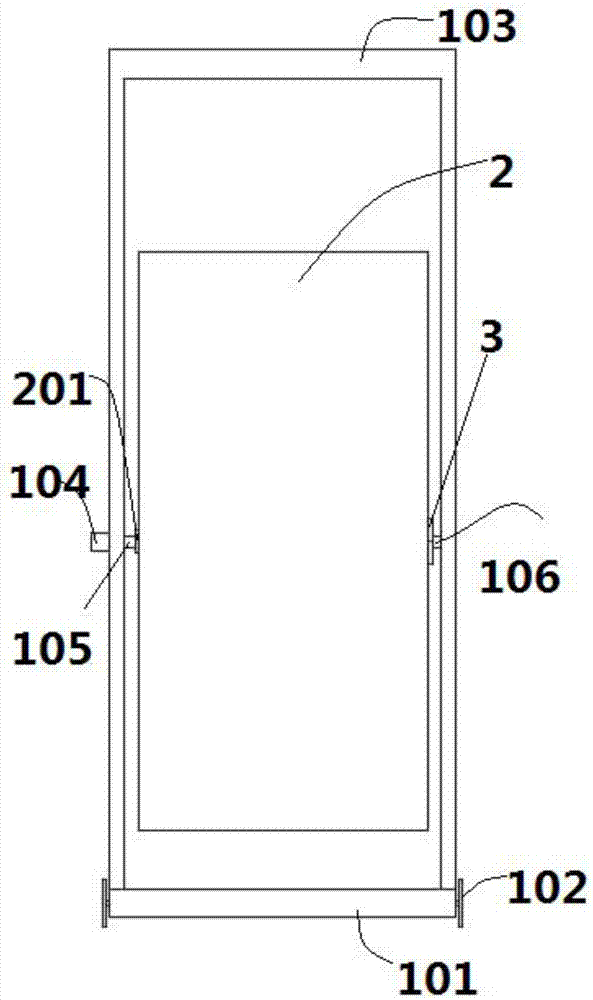

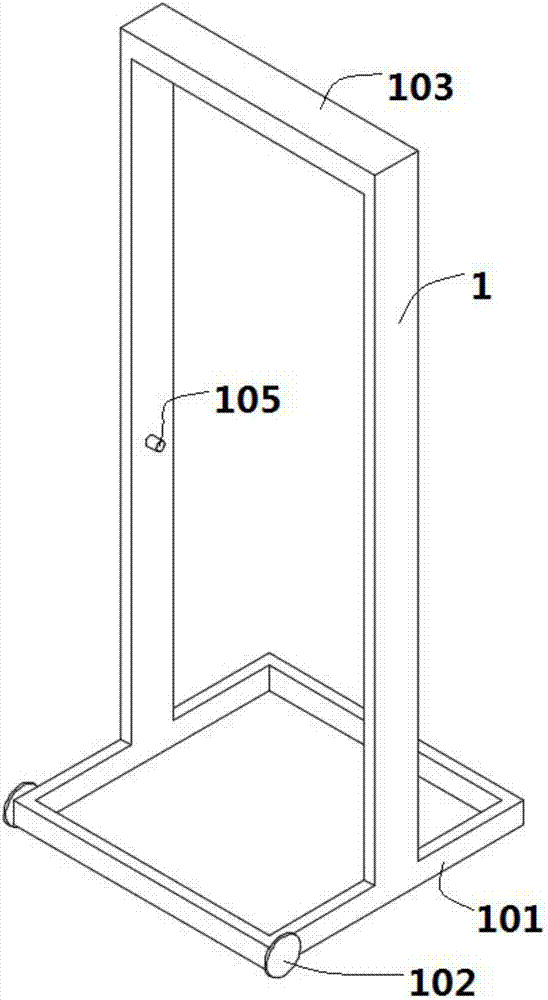

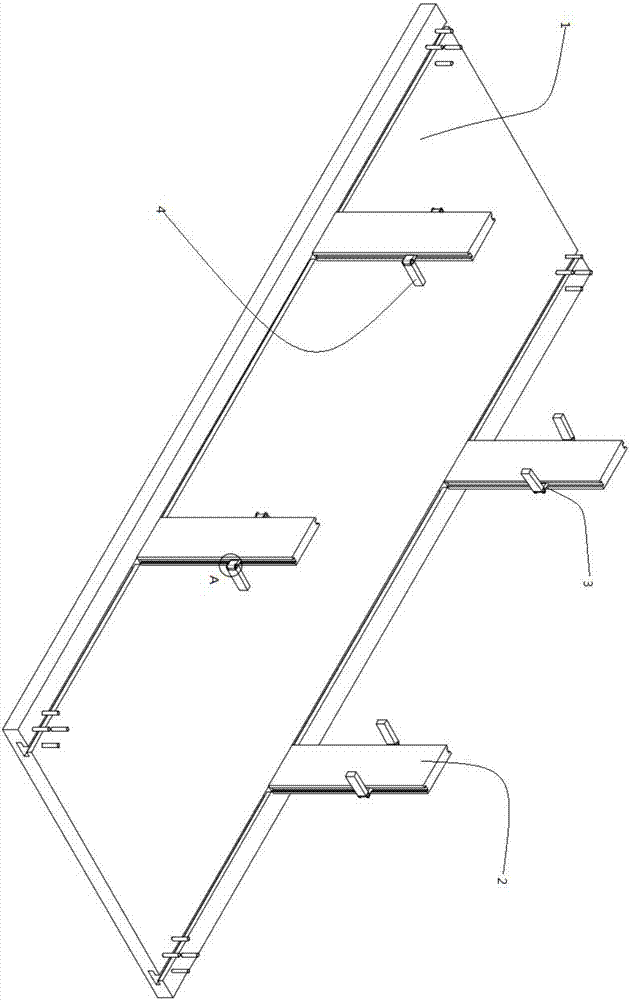

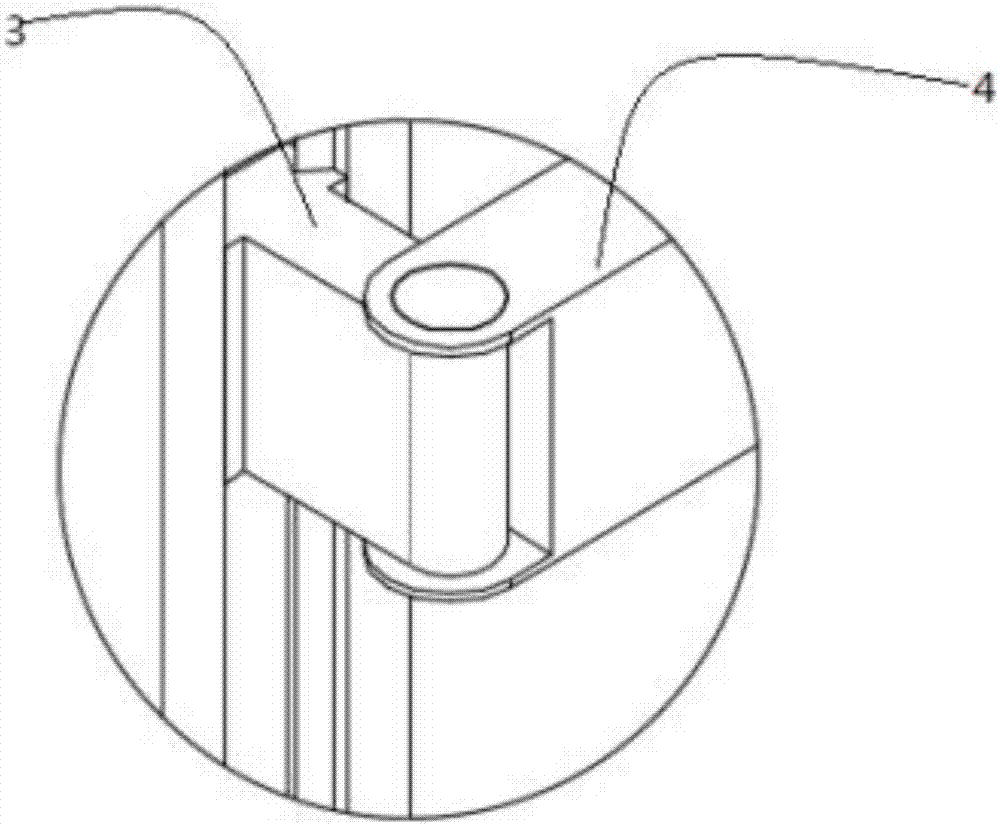

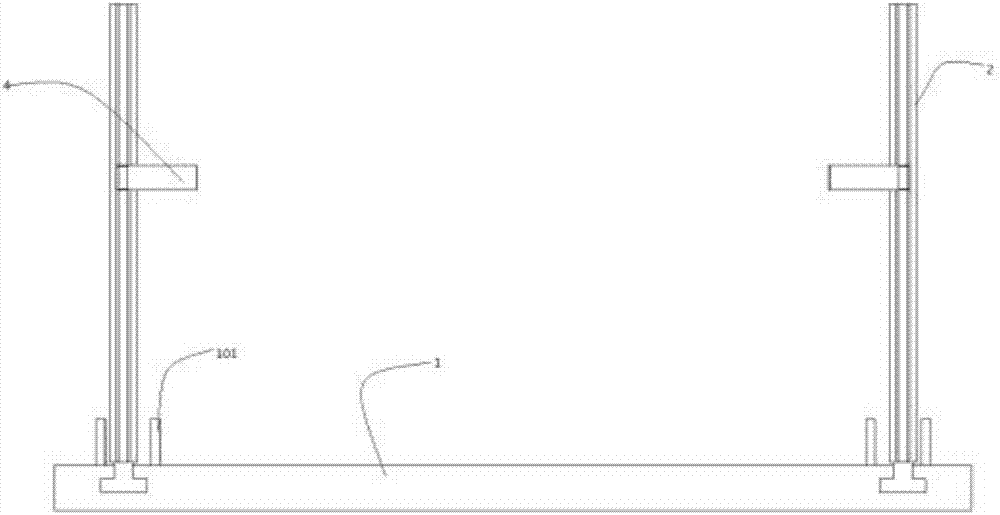

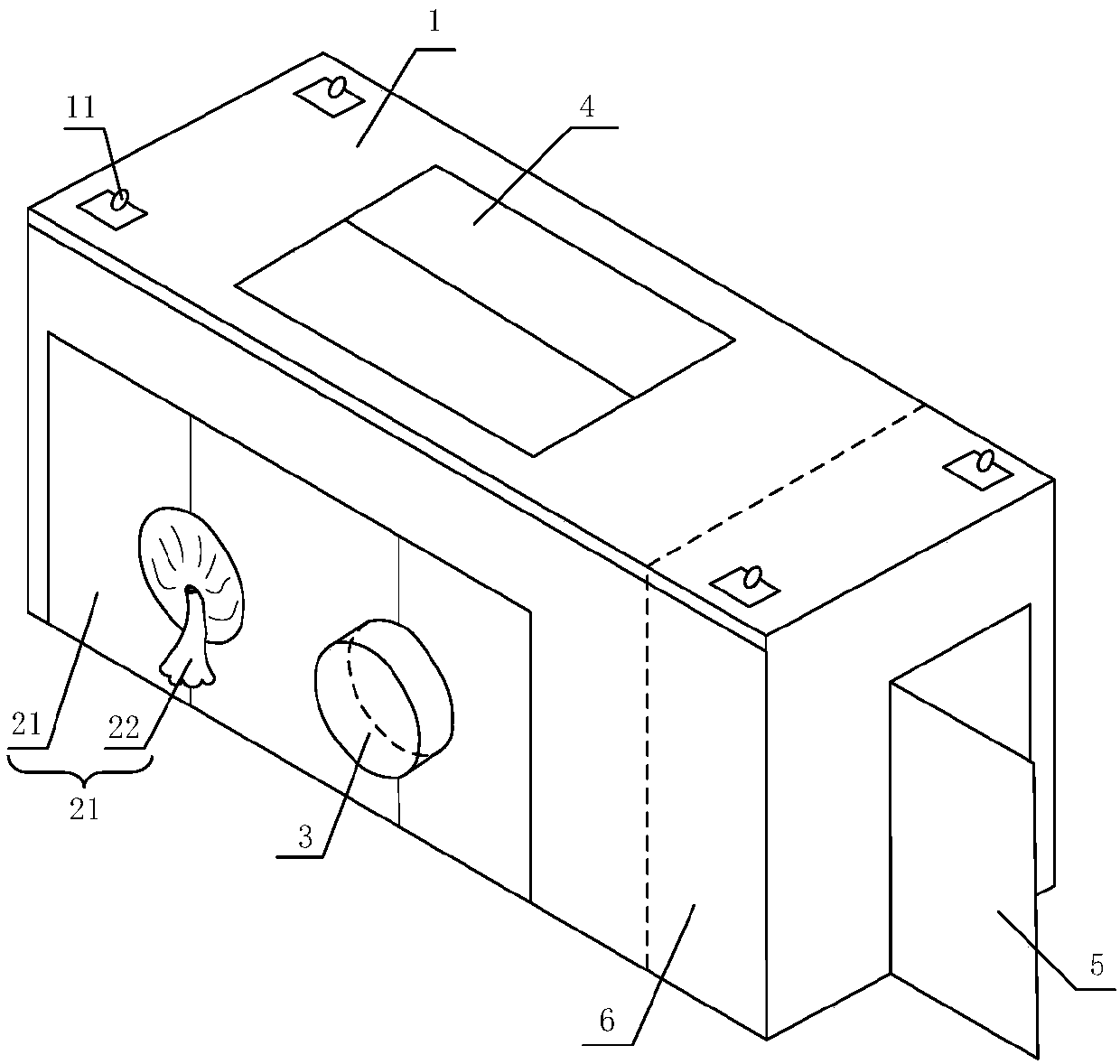

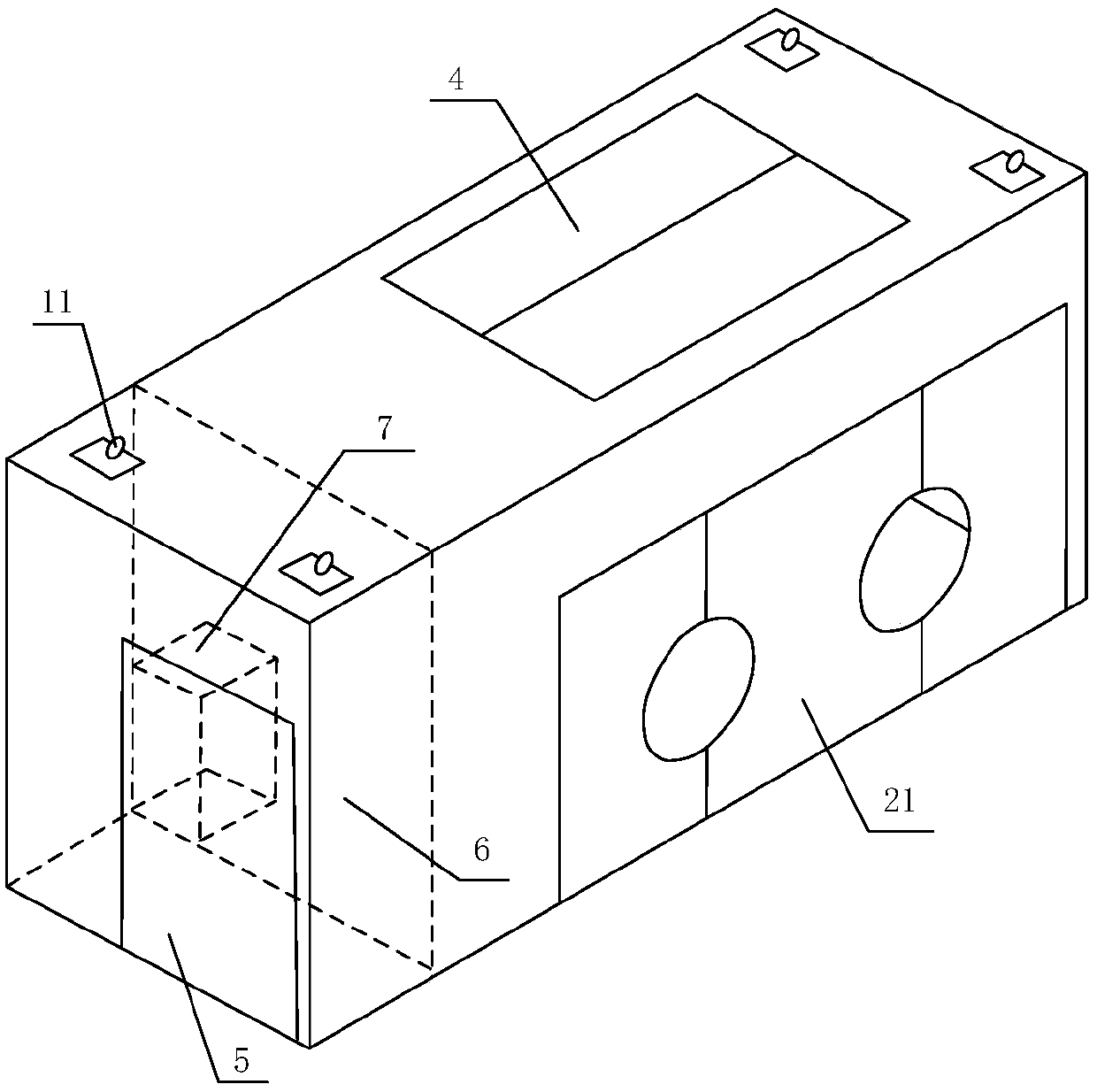

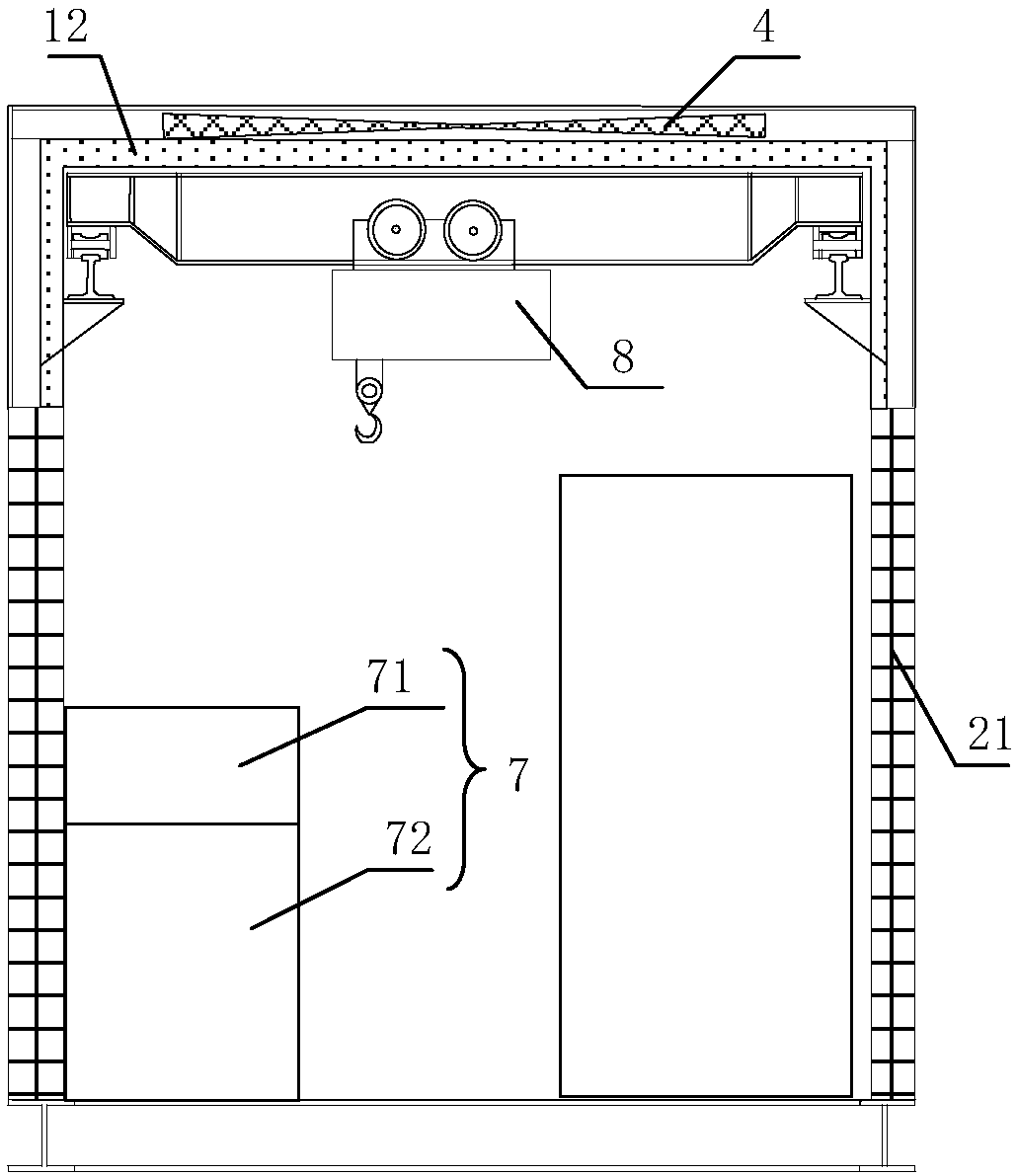

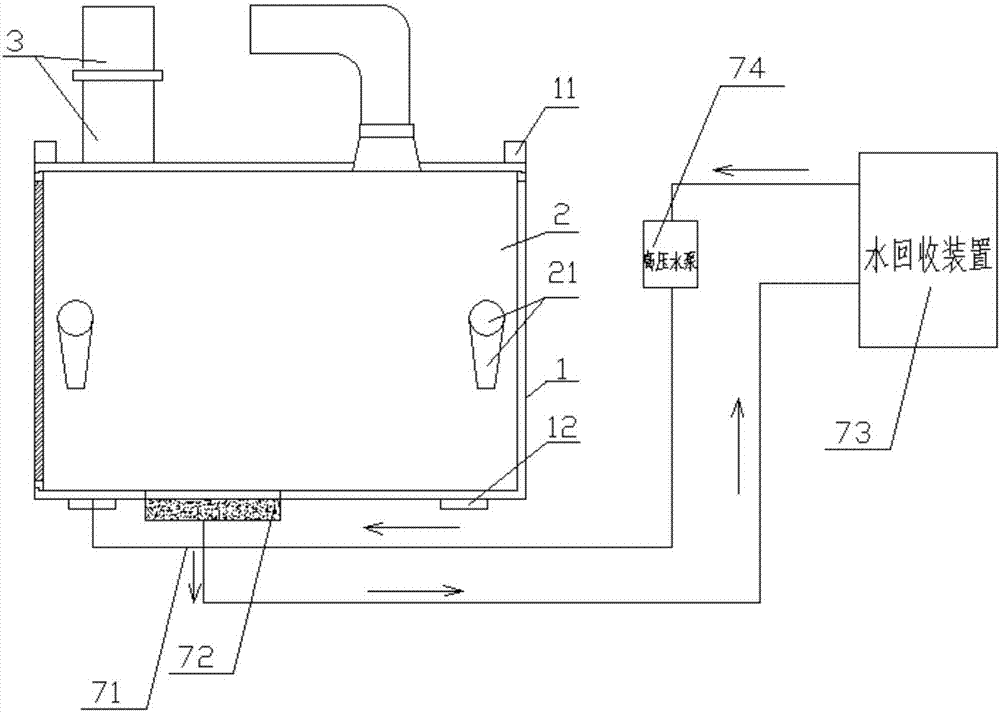

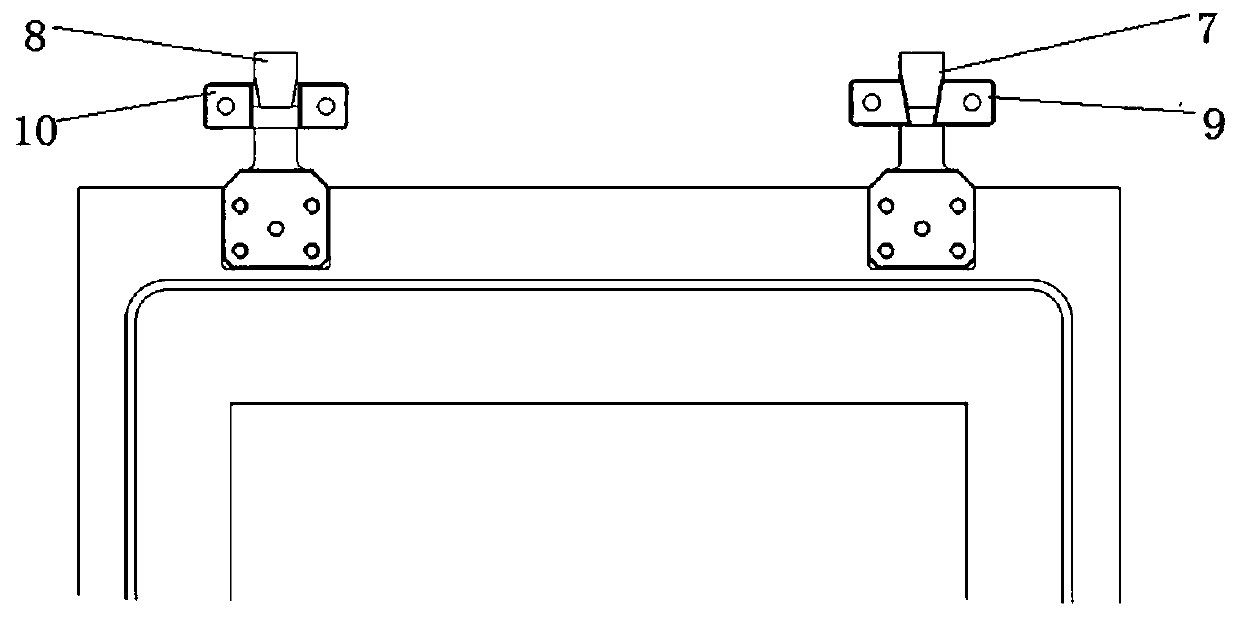

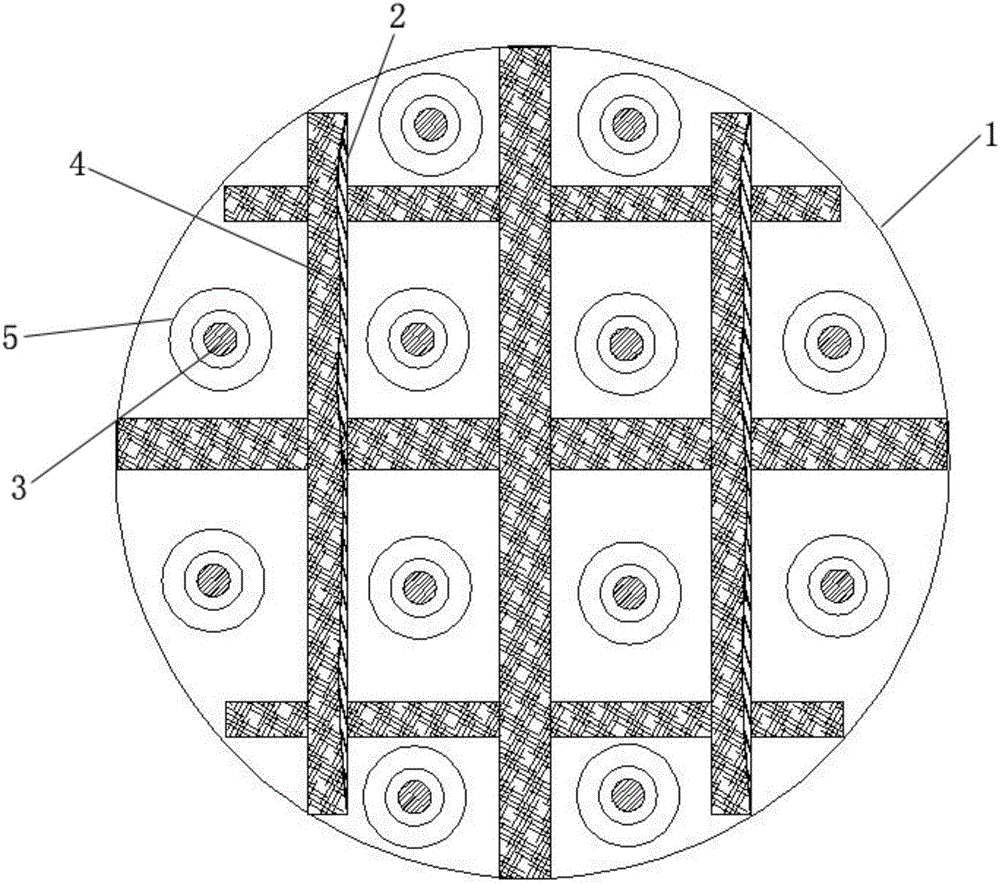

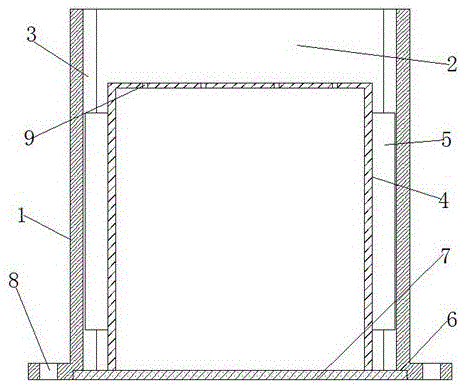

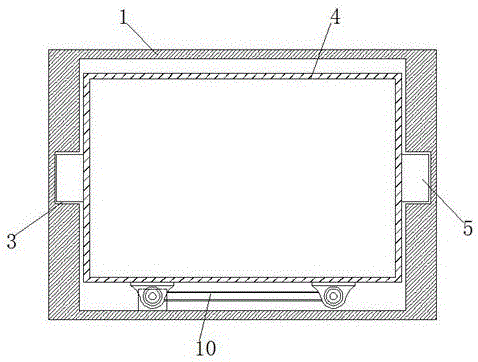

Dustproof room for GIS installation and maintenance

PendingCN107946995AReduce failureLow failure rateSubstation/switching arrangement casingsSwitchgearElectricityControl system

The invention discloses a dustproof room for GIS installation and maintenance and relates to the technical field of power equipment. The dustproof room is used for improving the installation and maintenance efficiency of a GIS and reducing the probability of a failure of the GIS. The dustproof room comprises a dustproof room main body capable of being carried to a GIS installation and maintenancepoint, wherein GIS placement openings are formed in the dustproof room main body and are provided with removable sealing curtains; a closed GIS installation and maintenance space is formed by the sealing curtains and the dustproof room main body; a plurality of lifting lugs are arranged outside the dustproof room main body; and a hoisting crane for hoisting the GIS, an environment control system for adjusting and controlling the environment of the GIS installation and maintenance space and a power supply lighting system for providing the hosting crane and the environment control system with electricity and lighting the GIS installation and maintenance space are arranged in the dustproof room main body separately. The dustproof room disclosed by the invention is applied to in-string equipment of the GIS.

Owner:STATE GRID CORP OF CHINA +4

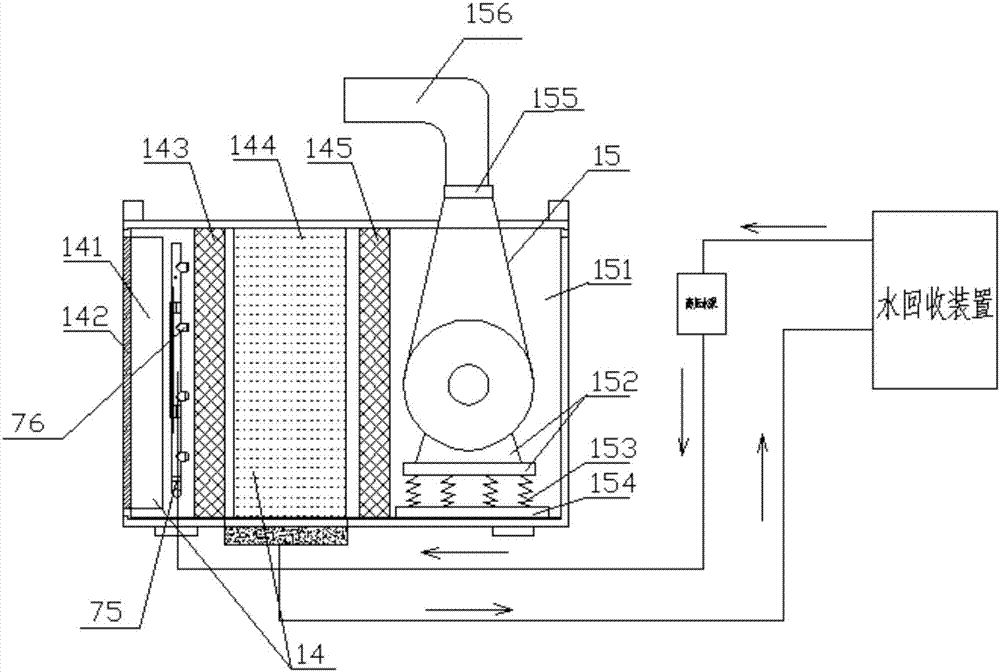

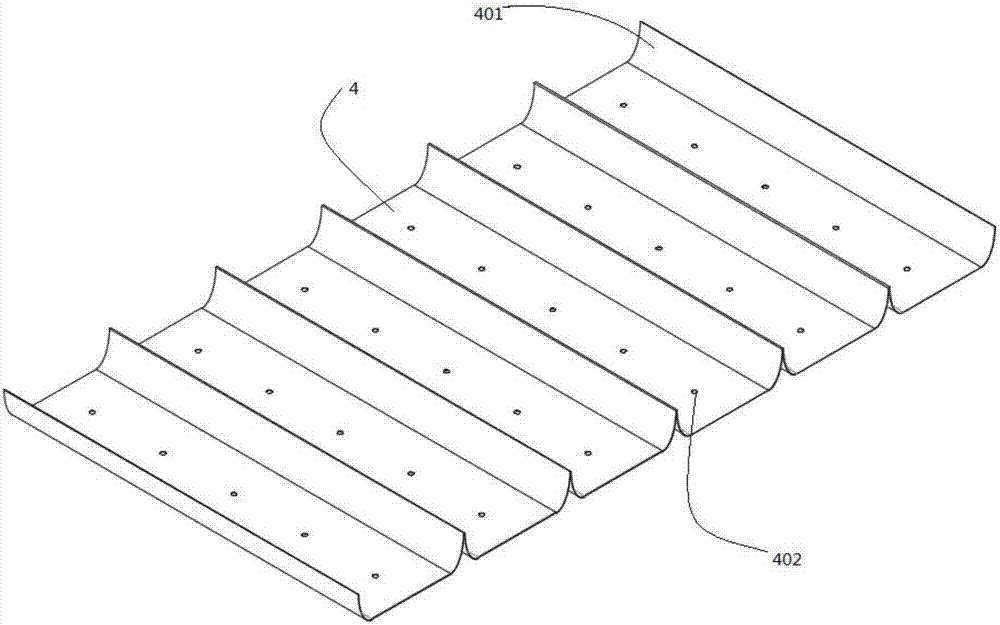

High-efficiency automatic self-cleaning ducted electronic dust removal and air purification device

InactiveCN107461815AQuick disassemblyEasy maintenanceMechanical apparatusCondensate preventionSprayerAlloy

The invention provides a high-efficiency automatic self-cleaning ducted electronic dust removal and air purification device which comprises an electronic dust removal and air purification machine protection shell, a quick-dismounting protection cover and a ducted air inlet pipe device. The ducted air inlet pipe device is arranged on the upper left portion of the electronic dust removal and air purification machine protection shell. The automatic self-cleaning device comprises a water hose, a stainless steel water pipe, a sprayer, a water pan, a water pump and a water bucket. Through arrangement of a quick-dismounting clamping groove and a quick locker, the quick-dismounting protection cover can be opened or closed quickly advantageously, and the original procedure of bolt connection design is omitted; a hollow-out stainless steel plate or hollow-out aluminum alloy plate is specifically adopted as an insect-proofing partition plate; and the ducted electronic dust removal and air purification device which can purify air with high efficiency and achieve automatic self-cleaning can be installed at a fresh air inlet or an air return port of an air conditioning unit through a flange, and is in seamless joint with an air pipe more conveniently.

Owner:河南昌铭环保设备有限公司

Front strap type portable hardware tool storage box for overhead operation

The invention relates to the technical field of hardware products, in particular to a front strap type portable hardware tool storage box for overhead operation. The front strap type portable hardware tool storage box comprises a storage box body comprising a rectangular main box. The left side of the rectangular main box is provided with a cavity box A and a cavity box B, a metal part cavity box is arranged in the middle of the rectangular main box, and the right side of the rectangular main box is provided with a cavity box C and a cavity box D. A nonmetallic part cavity box is arranged on the front portion of the metal part cavity box. The cavity box A and the cavity box B are respectively provided with a transparent cavity box cover A and a transparent cavity box cover B, and the left side and the right side of the transparent cavity box cover A and the transparent cavity box cover B are respectively provided with a reset spring A and a reset spring B. The portable hardware tool storage box is fixed on the human body via a front strap and provided with several tool cavity boxes with the reset springs and the transparent covers, so that tools can be taken and stored conveniently and cannot fall from the overhead, mounting and maintenance of professional maintenance operators are greatly facilitated, and mounting and maintenance efficiency is improved.

Owner:江苏项瑛农机有限公司

Six-way cascading rapid cable entry device

InactiveCN104300449AQuick plugPlug-in without boltsApparatus for joining/termination cablesRubber ringElectrical devices

The invention discloses a six-way cascading rapid cable entry device which comprises a link joint (2). A rubber ring (6) for fastening a cable is installed inside the link joint. Three holes are formed in the rubber ring. A steel plug board II (5) is installed at one end of the rubber ring. A steel plug board I (4) adjacent to the steel plug board II is installed inside the link joint. A steel gasket (3) is installed on one side of the steel plug board I. The steel gasket is connected with a compression nut (1) capable of extruding and fastening the rubber ring. The six-way cascading rapid cable entry device has the advantages that bolt-free quick plugging connection of at most four electrical devices with A1-type anti-explosion quick connectors can be achieved, meanwhile, the devices are in cascade connection through the anti-explosion quick connectors, the installation and maintenance efficiency of explosive-proof electrical products is improved, and labor intensity is lowered. The six-way cascading rapid cable entry device is internally provided with a high-intensity inflaming-retarding Kevlar weaving layer, the explosive gas volume inside the six-way cascading rapid cable entry device is decreased, and the anti-explosion performance of the six-way cascading rapid cable entry device is improved.

Owner:CHINA UNIV OF MINING & TECH +1

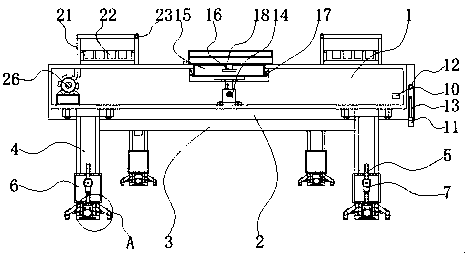

Chassis lifting device based on four-column lifter

The invention discloses a chassis lifting device based on a four-column lifter. The chassis lifting device comprises a supporting plate, an elastic element, a protective cover and a buckle, wherein the elastic element comprises a base; a spring is fixed on the surface of the base; a spring cover is fixed on the other end of the spring; the elastic element is fixed on the surface of the supporting plate through the base; a groove is formed in the middle of the protective cover; the groove and the supporting plate are mutually matched; anti-slip grooves are formed in the surfaces of both sides of the protective cover; and the buckle is fixed on the surface of the supporting plate. According to the chassis lifting device disclosed by the invention, through the arrangement of the elastic element, an automobile chassis can be better fitted with the supporting plate, and the automobile base can be better protected; the chassis lifting device has the advantages of being simple in structure and diverse in functions; through the arrangement of the protective cover, automobile tires run over the protective cover and then the protective cover is pulled away to protect the elastic element and the supporting plate; the chassis lifting device has the advantages of being high in durability, long in service life and the like; and the supporting plate is fixed through the buckle, an automobile is lifted through a wire rope, and an assembling manner between structures is reduced, so that structural materials are reduced, the production cost is reduced, and the mounting efficiency and the maintenance efficiency are improved.

Owner:SHANDONG HONGHAO ENERGY SAVING TECH CO LTD

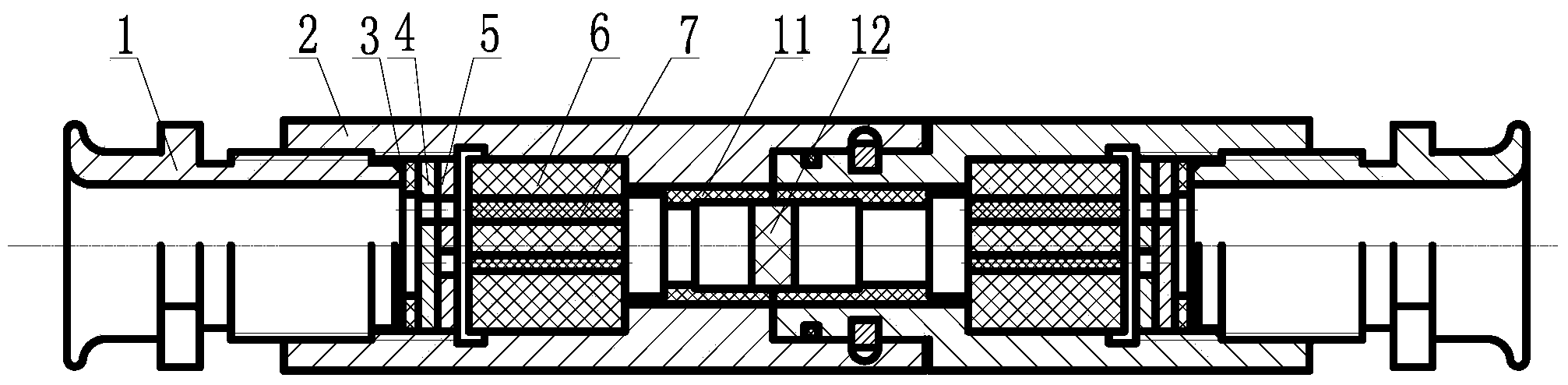

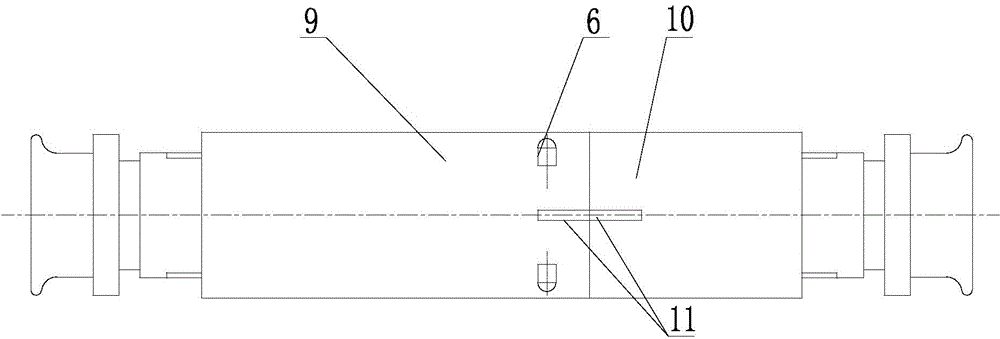

A1 type anti-explosion quick coupler for underground coal mine

InactiveCN104577940AReduce labor intensityImprove installation and maintenance efficiencyCable junctionsCable terminationsCoalEngineering

The invention discloses an A1 type anti-explosion quick coupler for an underground coal mine. The A1 type anti-explosion quick coupler comprises an anti-explosion steel jacket female head (9), wherein an anti-explosion steel jacket male head (10) is connected with one end of the anti-explosion steel jacket female head. The A1 type anti-explosion quick coupler has the benefits as follows: the device adopts a bolt-free two-stage explosive-proof structure, is in accordance with the explosion-proof criteria in the coal mine and free of other fastening tools, can realize manual and quick butt joint operation of the anti-explosion electric apparatus, obviously reduces the labor intensity of operation workers, and improves the efficiency of installation and maintenance of the anti-explosion electric apparatus; a Kevlar flame-retardant braid layer is arranged in the inner cavity of the device, so that the inner cavity explosive-proof gas volume can be reduced, and the explosive-proof capability can be obviously improved.

Owner:CHINA UNIV OF MINING & TECH

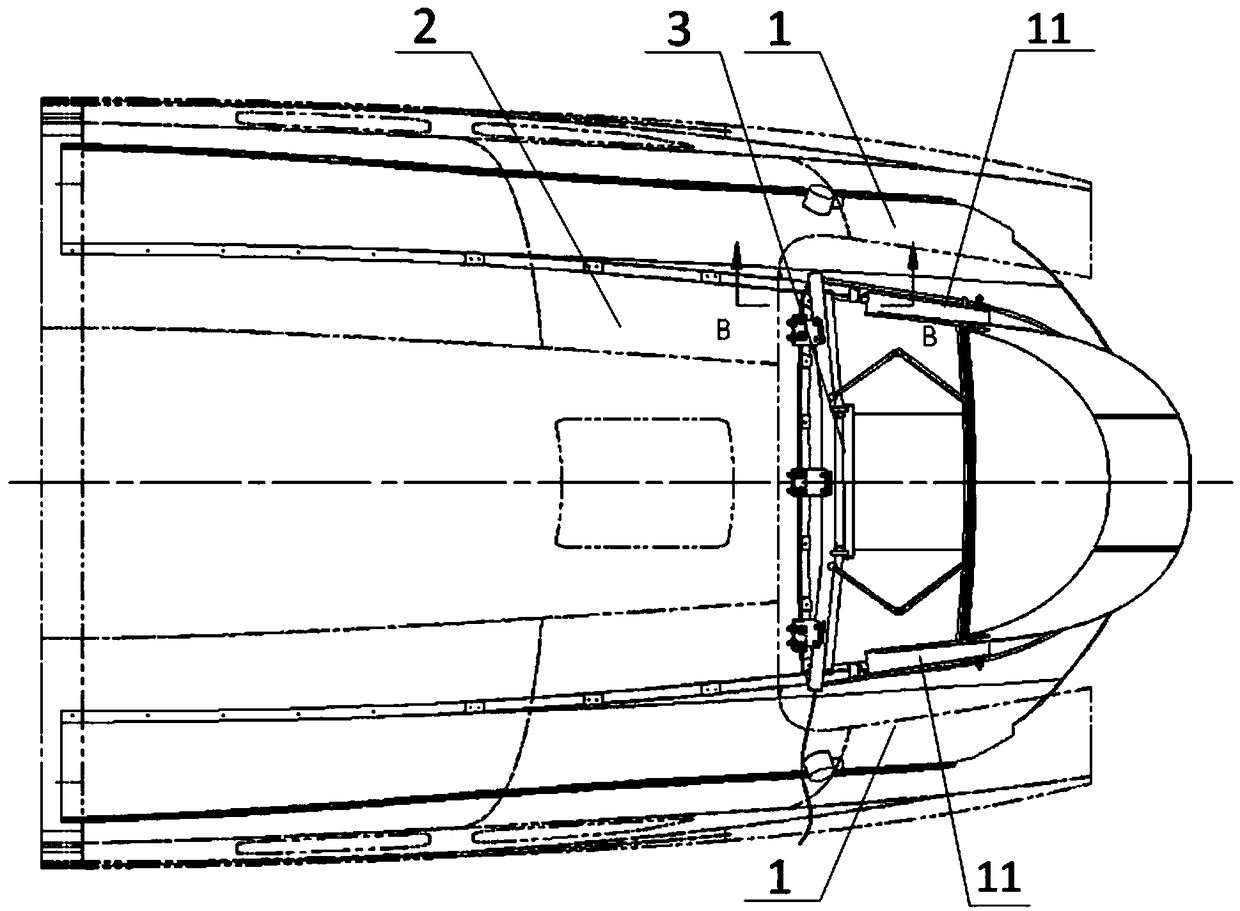

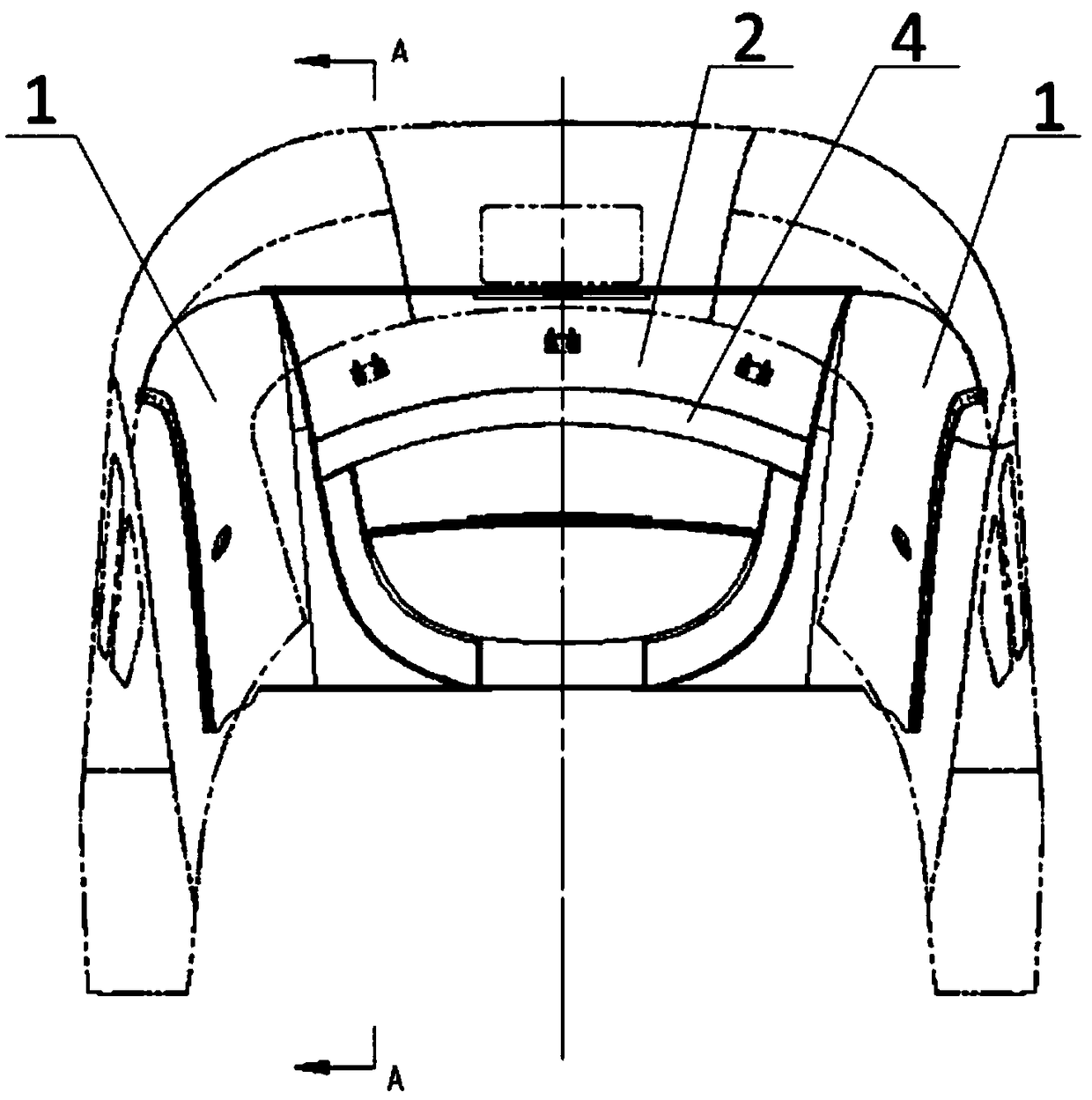

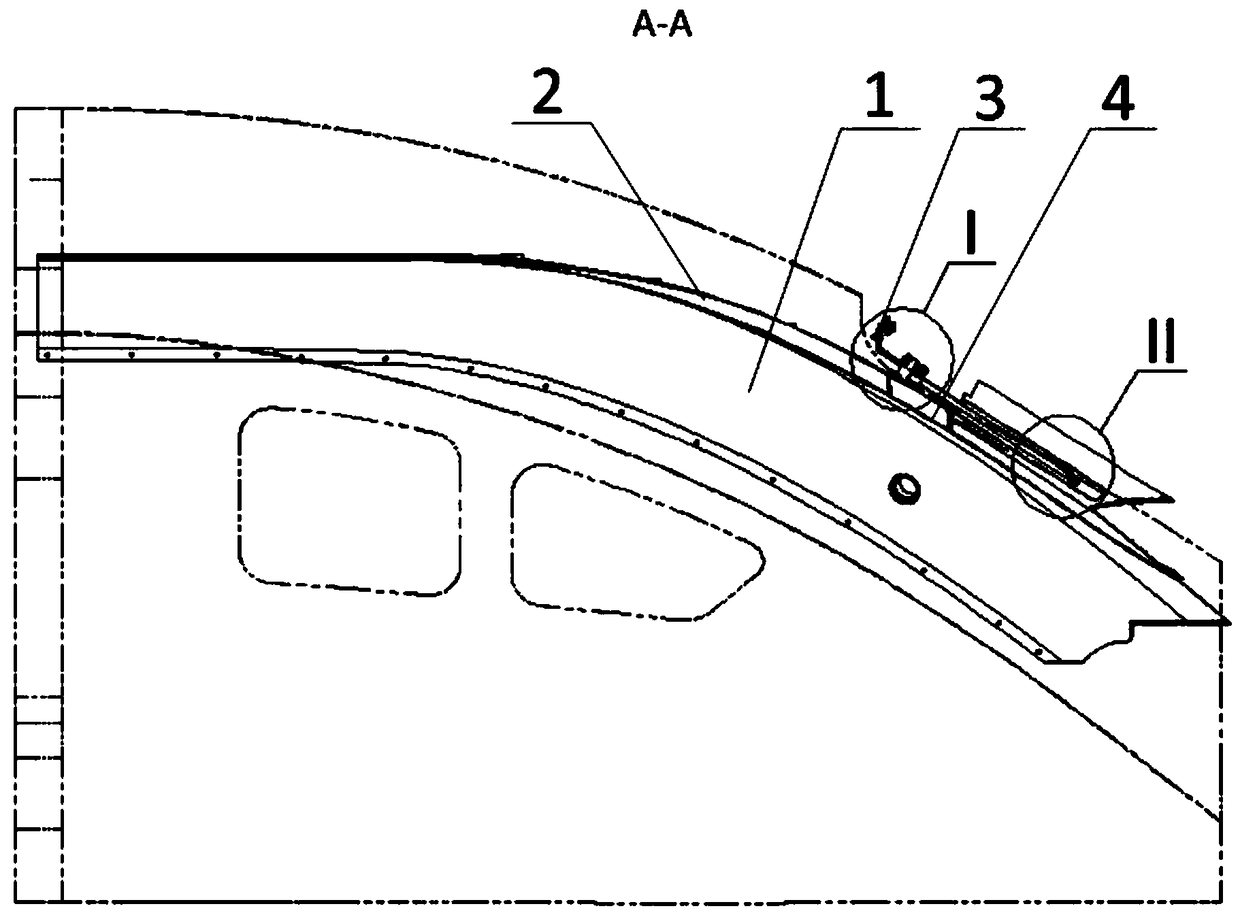

Abat vent mounting assembly

InactiveCN108825100AEasy to disassembleEasy maintenance and repairLight protection screensWindow arrangementsEngineeringFastener

The invention discloses an abat vent mounting assembly which comprises a left-right side decoration plate, a top decoration plate and an abat vent. The left-right side decoration plate is mounted on the side wall of a vehicle body in an embedded mode, and the top decoration plate is mounted at the top of the vehicle body in an embedded mode. An upper skeleton of the abat vent is detachably connected with the top of the vehicle body, and a guide rod is arranged at the bottom of the abat vent. A guide groove is formed in the inner wall of the left-right side decoration plate, and the guide groove and the guide rod are matched to be mounted so as to enable the guide rod to slide along the guide groove. According to the abat vent mounting assembly provided by the invention, by connecting the guide rod of the abat vent with the guide groove of the left-right side decoration plate in a hidden mode, compared with an exposed mounting mode in the prior art, the whole mounting structure and decoration have no various fastening pieces exposed, and decoration is attractive and high in grade; and meanwhile, the abat vent is detachably mounted together with the left-right side decoration plate and the top decoration plate, thus dismounting and mounting can be easy, maintenance and overhauling are convenient, and the mounting and maintenance efficiency is improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

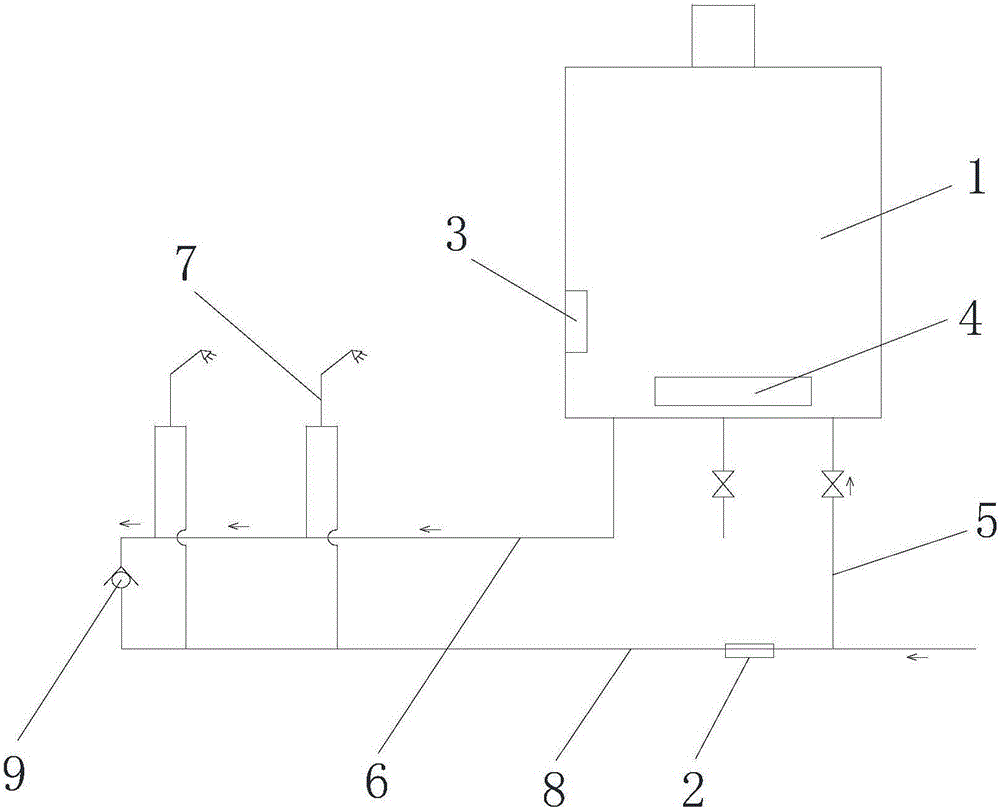

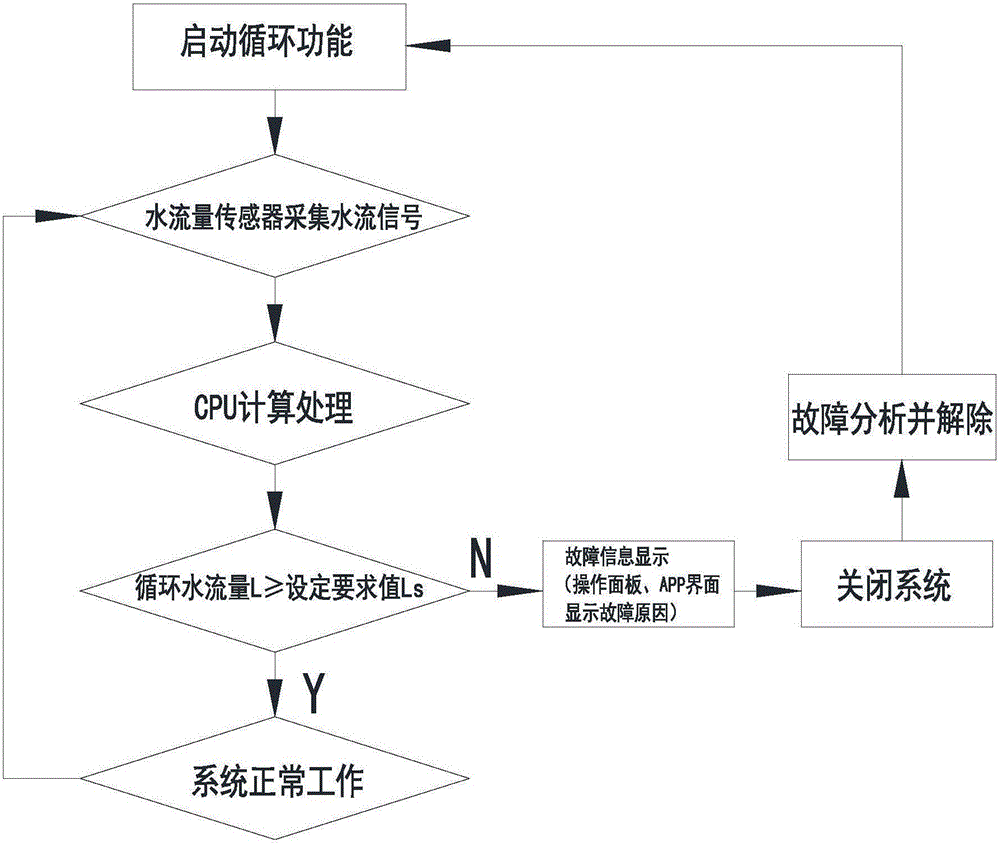

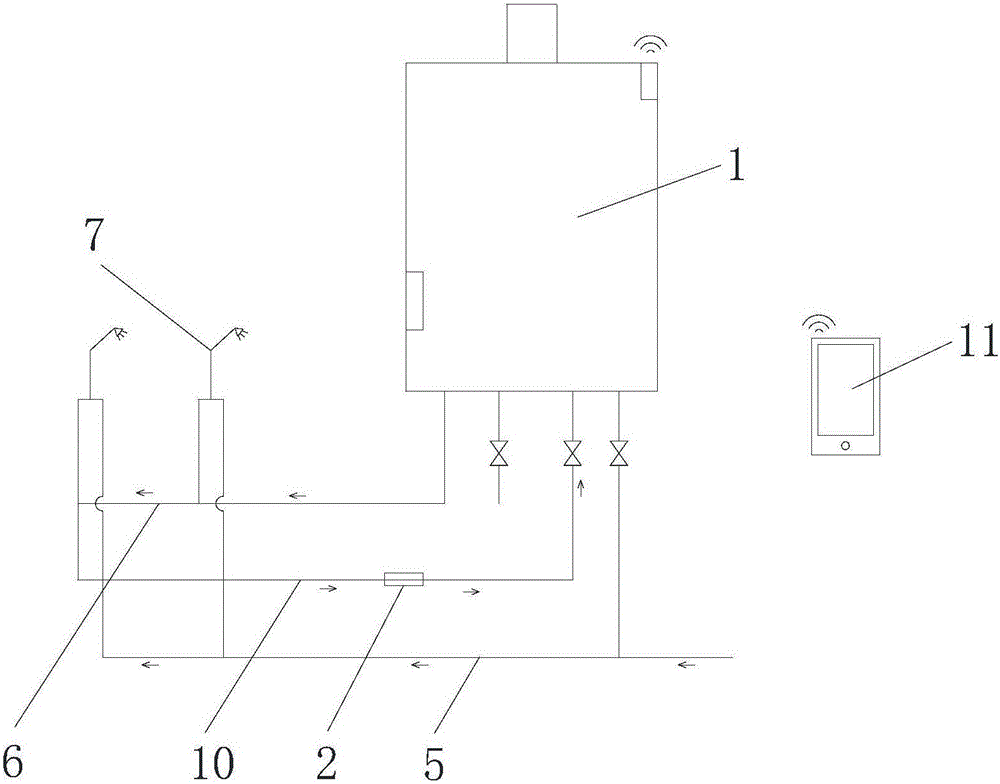

Intelligent protecting and prompting method for central gas water heater system

The invention discloses an intelligent protecting and prompting method for a central gas water heater system. The intelligent protecting and prompting method for the central gas water heater system is characterized in that the central gas water heater system comprises a central gas water heater body, a water flow rate sensor, a master controller and a displayer; the water flow rate sensor is used for detecting the water recirculation rate of the central gas water heater body; the master controller is connected with the water flow rate sensor to be used for analyzing signals detected by the water flow rate sensor; the displayer is connected with the master controller to be used for displaying fault information; and if the water flow rate sensor detects that the water flow rate is smaller than or equal to a set water flow rate within 1 min, the displayer gives out pre-warning to prompt jamming of circulation pipes. According to the intelligent protecting and prompting method for the central gas water heater system, water flow rate information of a circulation loop is acquired, statistically-calculated by the master controller, and then fed back to the displayer for displaying fault information such as jamming and exhausting, installation and maintenance personnel can be conveniently guided to install, adjust, test and maintain a central gas water heater, and the installation and maintenance efficiency is improved.

Owner:GUANGDONG MACRO GAS APPLIANCE

A combined sheet laser amplifier window assembly

PendingCN110943357APrevent overflowDegraded laser performanceSolid state laser constructional detailsEngineeringErbium lasers

The invention belongs to the field of high-power solid lasers, and particularly relates to a novel combined sheet-shaped laser amplifier window assembly. The assembly comprises a window frame sealingelement, a window frame, a window glass lower sealing element. The window glass, a window glass pressing pad and a pressing frame are sequentially arranged from inside to outside, and a first hook and a second hook which are symmetrically arranged are arranged at the upper end of the window frame and match a first positioning block and a second positioning block which are arranged on an amplifierclean box body for use. A window frame sealing piece is arranged on a mounting face, attached to an amplifier clean box body, of the window frame. Installation and detachment are more convenient, thepositioning accuracy is higher, accurate positioning and sealing can be completed under the action of self-gravity through translation and side hanging, the sealing performance is better, aerosol leakage is effectively prevented, and the assembling efficiency is higher.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Plugging method aiming at cables

InactiveCN106532597ARealize flexible installation processImprove protectionElectrical apparatusEngineeringMechanical engineering

The present invention discloses a plugging method aiming at cables. The method comprises the following steps: the step 1: fixing arranging supports at a circular output input hole in an inspection well to form a plurality of partitions for separating the cables from each other; the step 2: flexible waterproof adhesive tapes are arranged at the intervals between each partition; and the step 3: employing a fireproof air inflation sealing bag to wrap the cables, the fireproof air inflation sealing bag fully extrude the cables and the flexible waterproof adhesive tapes through air inflation expansion so as to realize the complete filling of the gaps between the partitions. The plugging method aiming at cables performs separation arrangement when the cables or optical cables are arranged in the circular output input hole in the inspection well, applies effective gap filling and has good sealing waterproof, fireproof and rat and ant prevention functions, so that the installation and maintenance are convenient and rapid, the service life is prolonged, and the accident rate is greatly reduced.

Owner:HANGZHOU HENGMA ELECTRIC POWER TECH

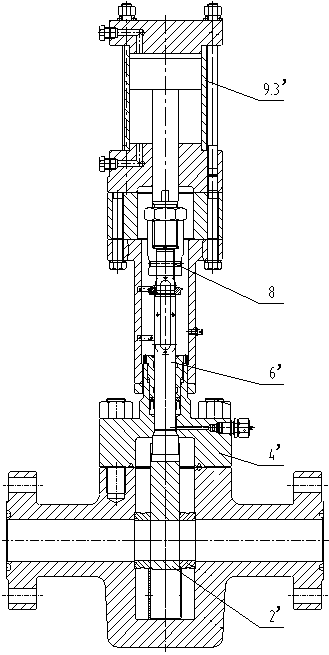

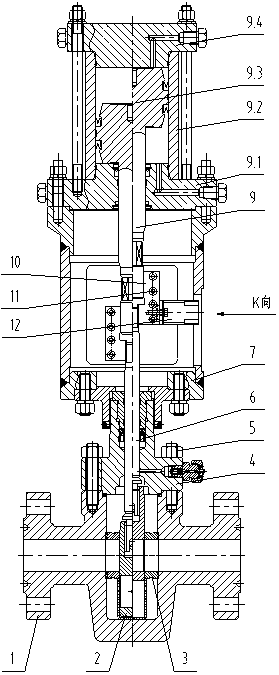

Hydraulic gate valve easy to commission

PendingCN109237062ASimple structureImprove installation and maintenance efficiencyOperating means/releasing devices for valvesSlide valveHydraulic cylinderPiston

The invention discloses a hydraulic gate valve easy to commission. The hydraulic gate valve comprises a valve body, a valve lid, a valve plate, a valve rod, a valve seat, a hydraulic cylinder, connecting blocks, an indicating block, a support, a lower hydraulic cylinder cover, a hydraulic cylinder barrel, a piston and an upper hydraulic cylinder cover, wherein a sealing groove is formed inside thevalve body which is fixedly connected with the valve cover; a threaded hole is formed in the upper portion of the valve plate which is arranged at the bottom of the sealing groove in the valve body;a thread is arranged at the bottom of the valve rod, the valve rod is in threaded connection with the valve plate, and the top of the valve rod penetrates through the valve cover; the valve seat is arranged inside the sealing groove in the valve body and located on the two sides of the valve plate; the first end of the hydraulic cylinder is fixed to the top of the valve rod; the connecting blocksare arranged on the two sides of the connecting position of the hydraulic cylinder and the valve rod to fix the hydraulic cylinder and the valve rod; the indicating block is fixed to the connecting block on one side and provided with an indicator board; the lower end of the support is fixedly connected with the top of the valve cover; the lower hydraulic cylinder cover is fixedly connected with the upper end of the support; the hydraulic cylinder barrel is arranged on the upper portion of the lower hydraulic cylinder cover, and the second end of the hydraulic cylinder penetrates through the lower hydraulic cylinder cover and is arranged inside the hydraulic cylinder barrel; the piston is fixed to the second end of the hydraulic cylinder; the upper hydraulic cylinder cover is arranged on the upper portion of the hydraulic cylinder barrel.

Owner:MEIZUAN SHENHAI ENERGY TECH RES & DEV SHANGHAI CO LTD +1

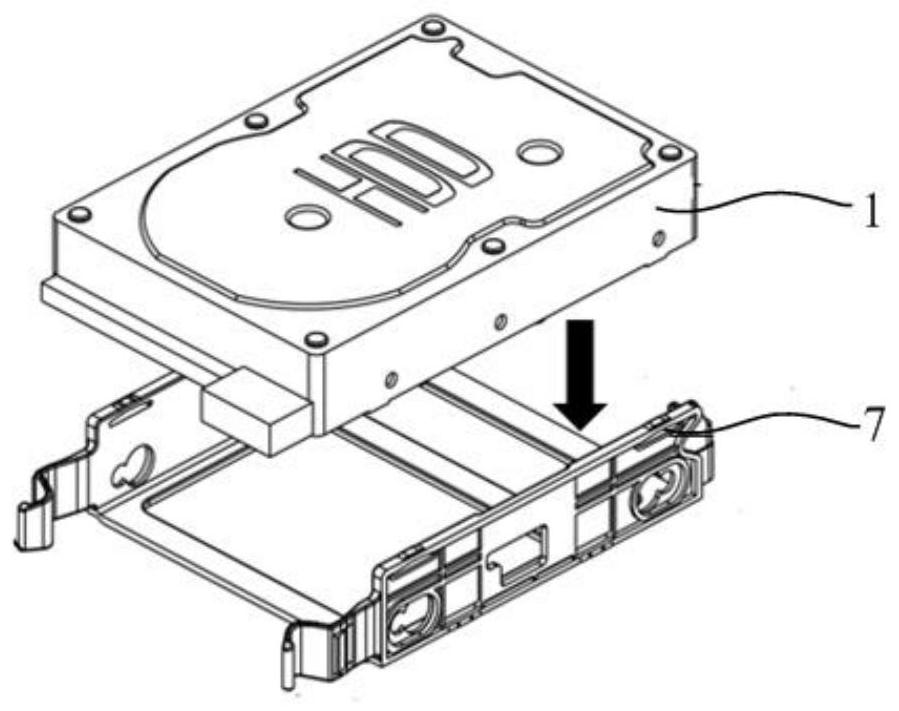

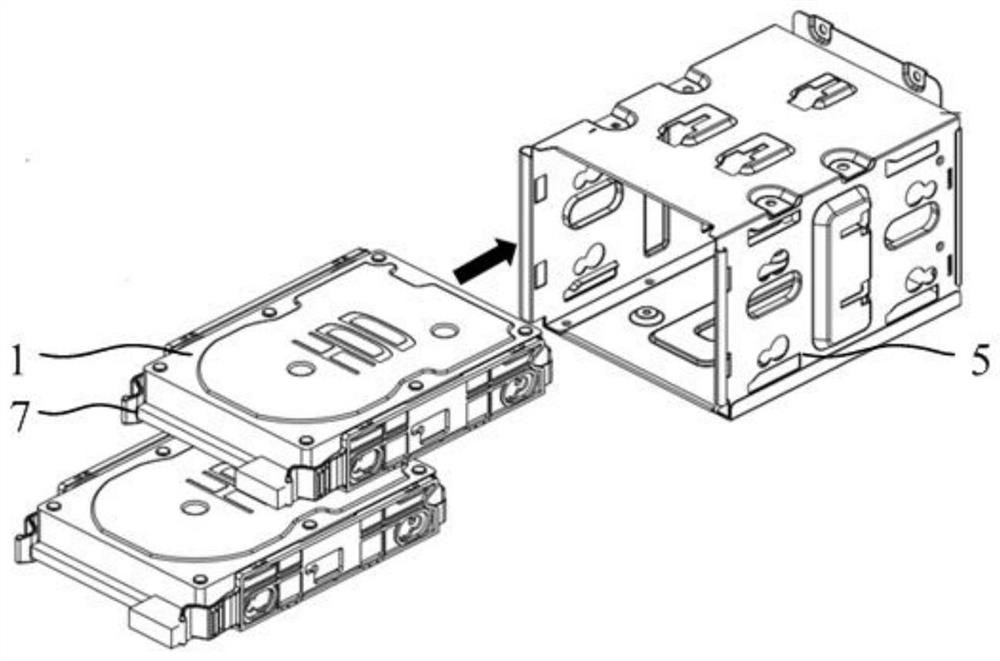

Bus-mounted hard disk video recorder installation bracket

InactiveCN105905042AAutomatic control accessImprove installation and maintenance efficiencyVehicle componentsAutomatic controlTime efficient

The invention discloses a bus-mounted hard disk video recorder installation bracket. The bus-mounted hard disk video recorder installation bracket comprises a T-shaped shell body; a groove is formed in one end of the T-shaped shell body and sleeved with a cover plate, and sliding chutes are symmetrically formed in the inner wall of the T-shaped shell body with respect to the center; the T-shaped shell body is internally provided with a containing cavity, a containing bin is arranged in the containing cavity, and slide rails are arranged on the two sides of the containing bin and matched with the sliding chutes; installation holes are formed in the end, away from the groove, of the containing bin; and the containing bin is connected with the T-shaped shell body through a transmission device, and the T-shaped shell body is provided with threaded holes. According to the bus-mounted hard disk video recorder installation bracket, a bus-mounted hard disk video recorder can slide on the T-shaped shell body along with the containing bin, and the purpose that the bus-mounted hard disk video recorder moves on the T-shaped shell body front and back is achieved, so that a wiring is convenient to install, and maintenance and dismantling are easy; and the purpose that the bus-mounted hard disk video recorder is automatically controlled to enter and exit is achieved, the installing efficiency and the maintaining efficiency of the bus-mounted hard disk video recorder are improved, and the time is saved.

Owner:ANHUI FUHUANG TECH CO LTD

Wind pipe machine

ActiveCN105258216AEasy maintenanceSimple and convenient replacement processCondensate preventionLighting and heating apparatusEngineeringElectric control

The invention provides a wind pipe machine. The wind pipe machine comprises a shell body and a side plate assembly. An installation cavity is formed by the shell body in an enclosed mode. One end of the installation cavity is provided with an opening. An air channel air outlet, a heat exchanger, a pipe temperature sensor and an electric control box assembly are arranged in the installation cavity. The side plate assembly is arranged at the opening of the installation cavity and closes the of the installation cavity. The side plate assembly is provided with a universal maintenance opening. The air channel air outlet, the heat exchanger and the pipe temperature sensor can be examined through the maintenance opening, and the pipe temperature sensor is maintained or replaced. According to the a wind pipe machine, the side plate assembly is arranged at the opening of the installation cavity and closes the of the installation cavity; the air channel air outlet, the heat exchanger and the pipe temperature sensor can be examined through the maintenance opening in the side plate assembly, and the pipe temperature sensor is maintained or replaced, so that the traditional conditions that maintenance is conducted by detaching a top cover and a water-containing disk are avoided, and accordingly the pipe temperature sensor is maintained or replaced conveniently and simply, and the installation-maintenance efficiency of the product is improved. Therefore, the production efficiency of the product is improved. The occupying space is small. The application range of installation sites is wide.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

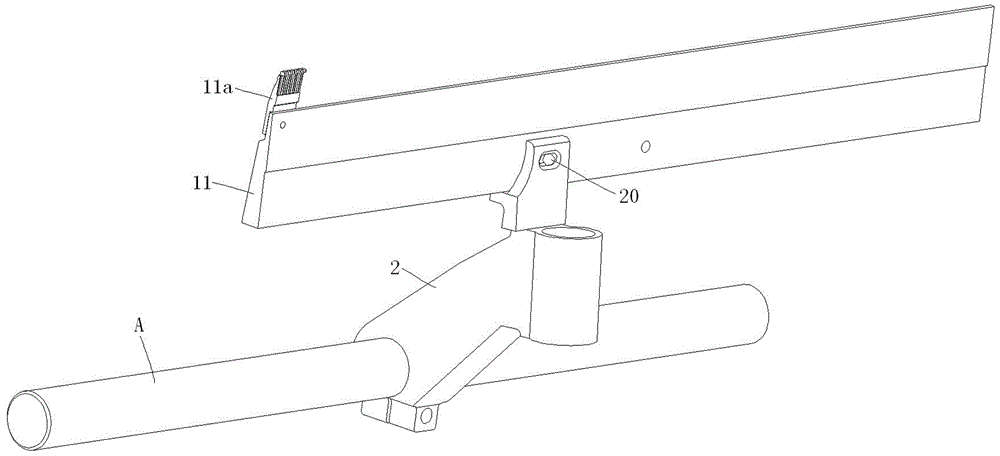

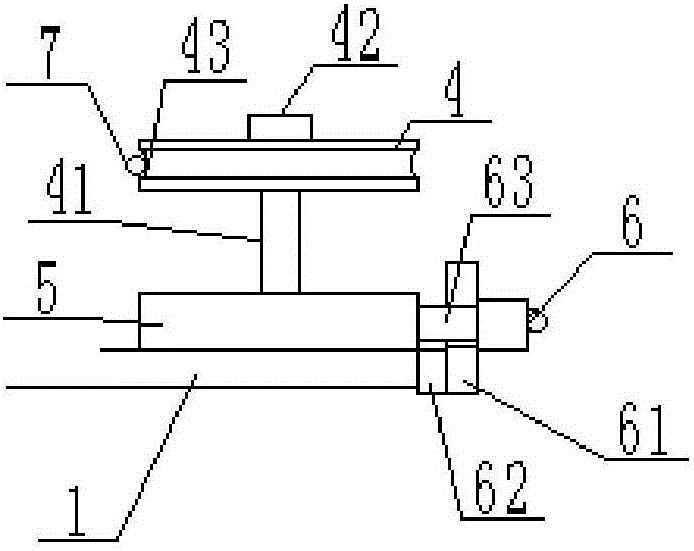

Coil-forming transmission mechanism of warp knitting machine

InactiveCN106835487ASave installation and maintenance timeHigh working reliabilityWarp knittingStub axleFuel tank

The invention discloses a coil-forming transmission mechanism of a warp knitting machine. The coil-forming transmission mechanism comprises a groove pin mechanism, a pin core mechanism, a coil slippage mechanism, a settling mechanism and an oil tank main shaft, wherein the groove pin mechanism comprises a groove pin main shaft, a groove pin swing arm, a guide arm, a groove pin bed bracket, a groove pin bed and a groove pin connecting rod mechanism; the front end of the groove pin swing arm is rotatably connected with the upper end of an oil tank output rod; the rear end of the groove pin swing arm is fixedly connected with the groove pin main shaft; the front end of the guide beam is in sliding connection with the groove pin bed bracket; the rear end of the guide arm is fixedly connected with the groove pin main shaft; the pin core mechanism comprises a pin core bed, a pin core bracket, a short shaft and a pin core oil tank output rod; the coil slippage mechanism comprises a coil slippage pin bed; the settling mechanism comprises a settling pin bed, a settling swing arm and a settling connecting rod; the lower end of the pin core bracket is rotatably connected with the upper end of the pin core oil tank output rod directly; the lower end of the pin core oil tank output rod is in rolling connection with a pin core cam; and the coil slippage pin bed is fixedly mounted on the guide arm. According to the coil-forming transmission mechanism disclosed by the invention, the mechanism is simplified, the mounting time is reduced, and the working reliability, and the mounting precision and efficiency are improved.

Owner:常州市润源提花经编机制造有限公司

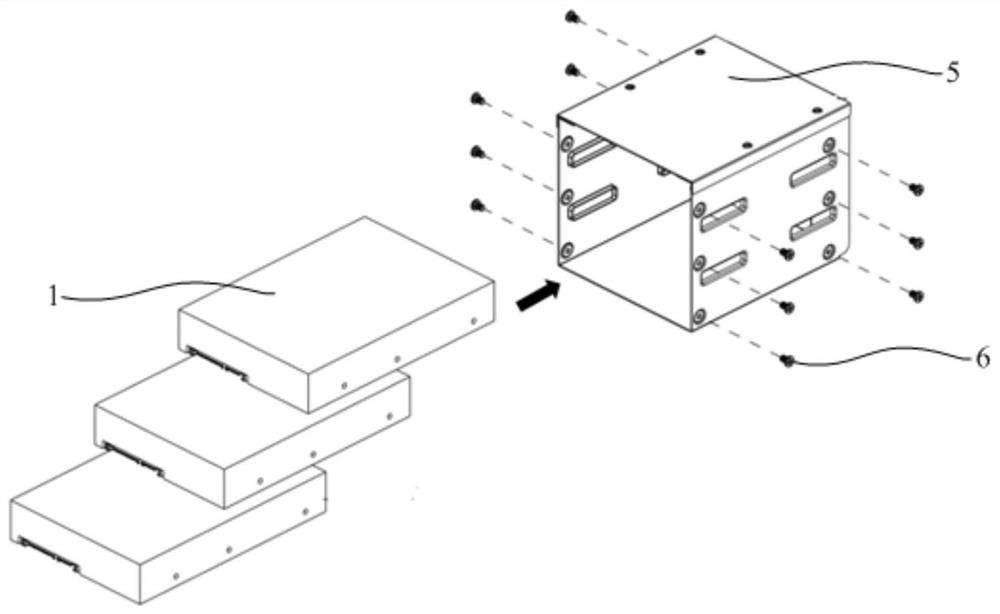

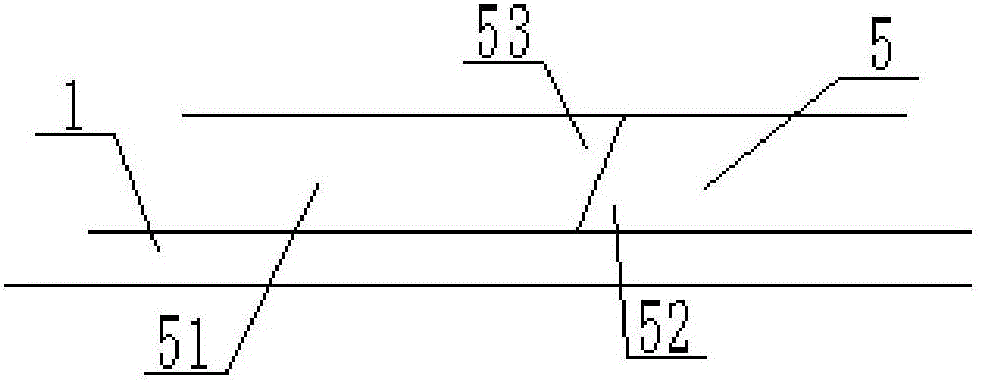

Hard disk fixing device and host

ActiveCN111625056AReduce installation stepsImprove installation and maintenance efficiencyUndesired vibrations/sounds insulation/absorptionDigital processing power distributionRotational axisEngineering

The invention provides a hard disk fixing device and a host, relates to the technical field of computers, and aims to solve the problems of complex hard disk installation and maintenance operation andlow working efficiency. The hard disk fixing device comprises a handle, a locking piece, a transmission piece and a hard disk frame, a locking hole is formed in the first side surface of the hard disk frame; the locking holes are used for fixing parts of the hard disk to extend out of the hard disk frame; the handle is connected with the first side face through a rotating shaft, the transmissionpiece is rotationally connected with the handle, the locking piece is rotationally connected with the transmission piece, the rotating center line of the transmission piece rotating relative to the handle and the rotating center line of the locking piece rotating relative to the transmission piece are both parallel to the center line of the rotating shaft, and a locking bayonet in the locking piece is clamped with the fixing piece. According to the hard disk fixing device, the locking piece, the transmission piece and the handle are used for locking the hard disk in the hard disk frame and unlocking the hard disk, the hard disk can be assembled and disassembled under the condition that the hard disk frame is not disassembled, and the installation and maintenance efficiency of the hard diskis improved.

Owner:XIAN YIPU COMM TECH

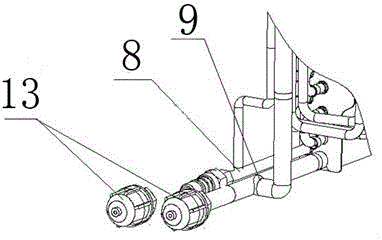

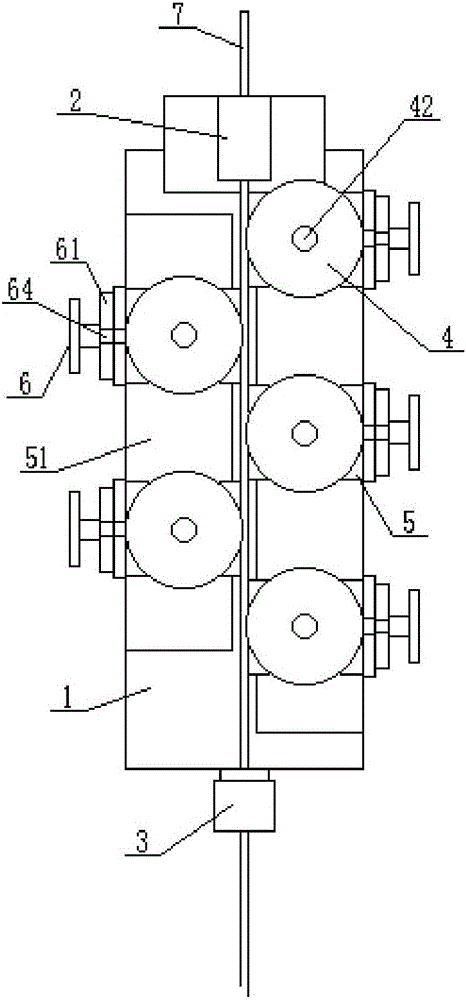

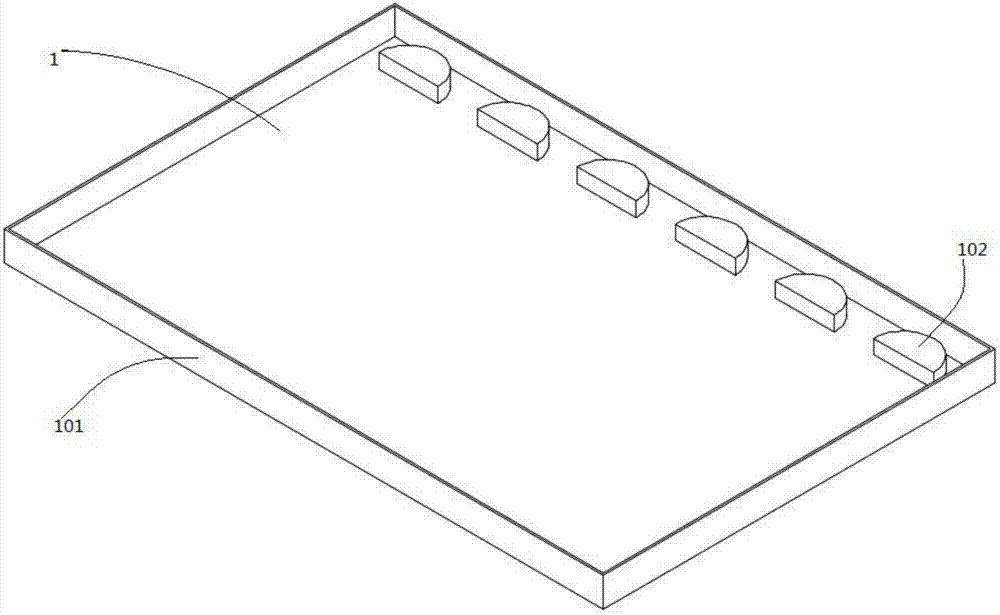

Material guiding mechanism of hook bolt forming machine

InactiveCN106166596AImprove guidanceGuarantee the quality of workHandling devicesMechanical engineeringWheel and axle

The invention discloses a material guiding mechanism of a hook bolt forming machine. The material guiding mechanism comprises a bottom plate, an upper guide block, a lower guide block, guide wheels, a plurality of installation plates, adjusting handles and a material wire. The upper guide block is installed at one end of the bottom plate, the lower guide block is installed at the other end of the bottom plate, the upper guide block and the lower guide block are located on the same central line of the bottom plate, the installation plates are further installed at the upper end of the bottom plate, wheel shafts and handle shafts are installed on the installation plates, the wheel shafts are located on the tops of the installation plates, the handle shafts are located on the side faces of the installation plates, the guide wheels are installed on the wheel shafts, the adjusting handles are installed on the handle shafts, the material wire penetrates through the upper guide block and the lower guide block to be in fit contact with the guide wheels, and fixing plates are distributed on the opposite sides of the bottom plate in a spaced mode. By means of the material guiding mechanism of the hook bolt forming machine, the material wire can be well guided to be straight, and the working quality can be ensured; meanwhile, the installation and maintenance efficiency is improved due to the simple structure.

Owner:新昌县新剡轴承有限公司

Simple stereoscopic parking garage based on hydraulic lifting

Owner:湖北亘华工科有限公司

Detection platform for big data observation and with folding and stretching function

ActiveCN109158140AQuick open closeEasy to control the angleLaboratory benches/tablesEngineeringMotherboard

The invention relates to a detection platform for big data observation and with a folding and stretching function. The detection platform comprises a main plate, a bracket, a hanging ring and a placing rack; a sliding groove is formed below the main plate; a secondary plate is arranged on the inner side of the sliding groove; the main plate is fixedly connected with the sliding groove; the slidinggroove is movably connected with the secondary plate; the bracket is arranged on the outer side of the sliding groove; a toothed clamping strip is arranged on the outer side of the bracket; the bracket is in screw connection with the main plate; the bracket is in adhesion connection with the toothed clamping strip; a push ring is arranged on the outer side of the toothed clamping strip; a push block is arranged above the push ring; the toothed clamping strip is movably connected with the push ring; the push ring is movably connected with the push block; and the bottom of the push block is connected with a clamping spring. The detection platform has the following beneficial effects: the detection platform for big data observation and with the folding and stretching function is provided with the secondary plate, and the secondary plate can effectively increase the integrated area of the device, so that the use range of the device is wider.

Owner:董钢

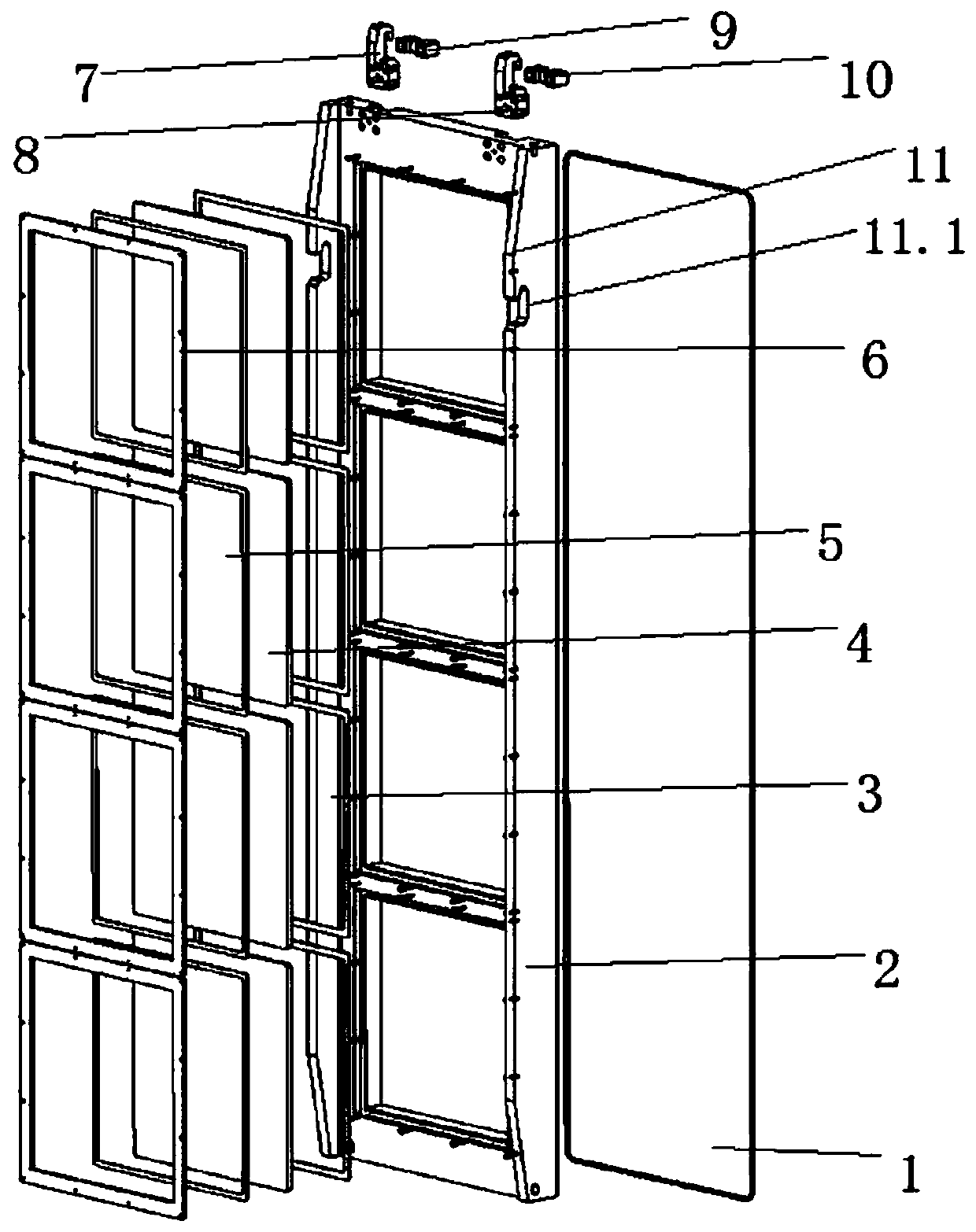

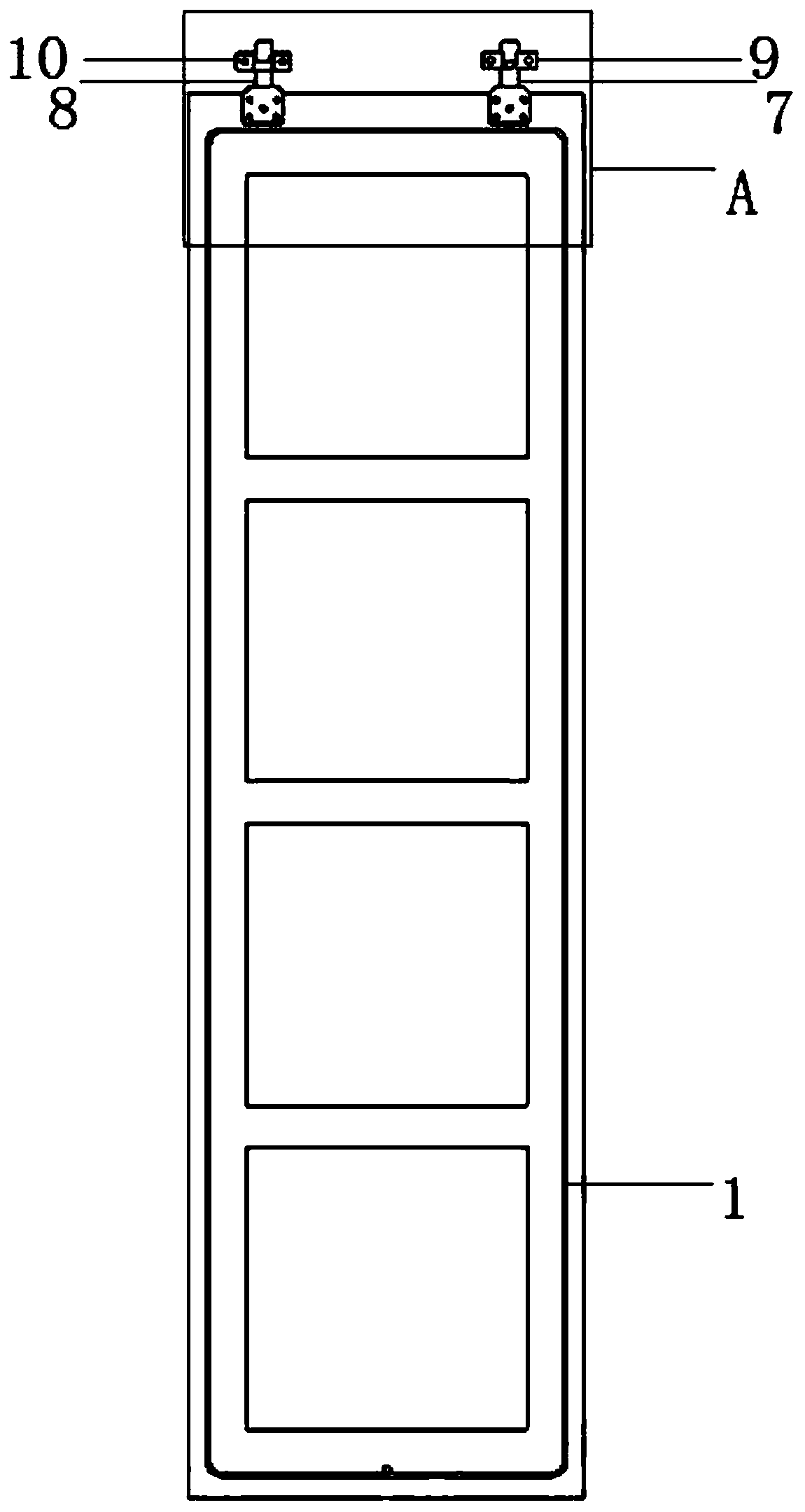

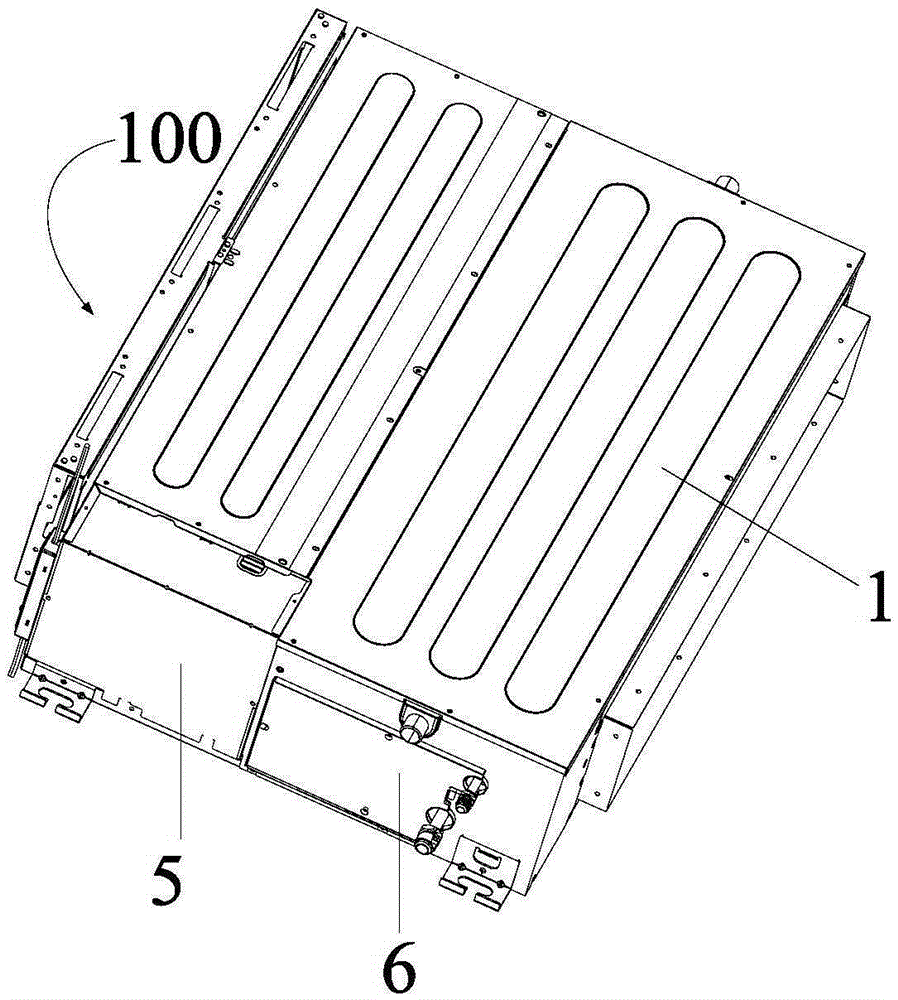

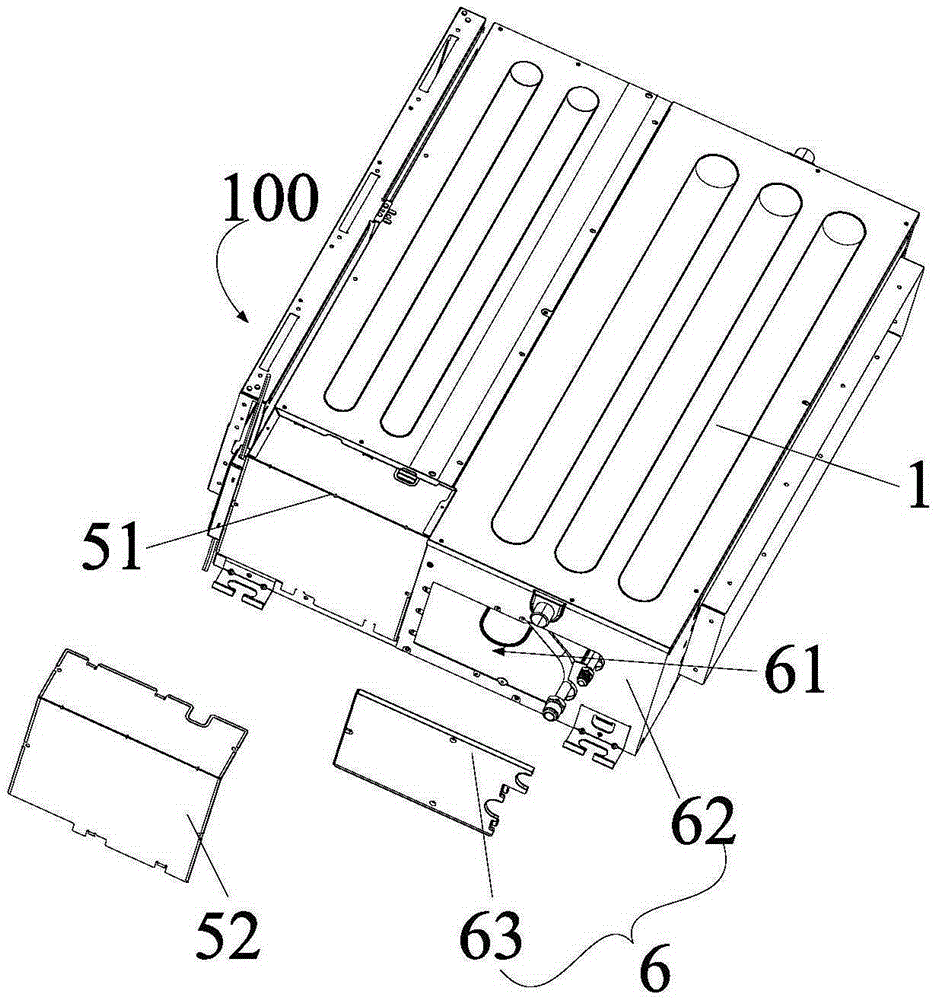

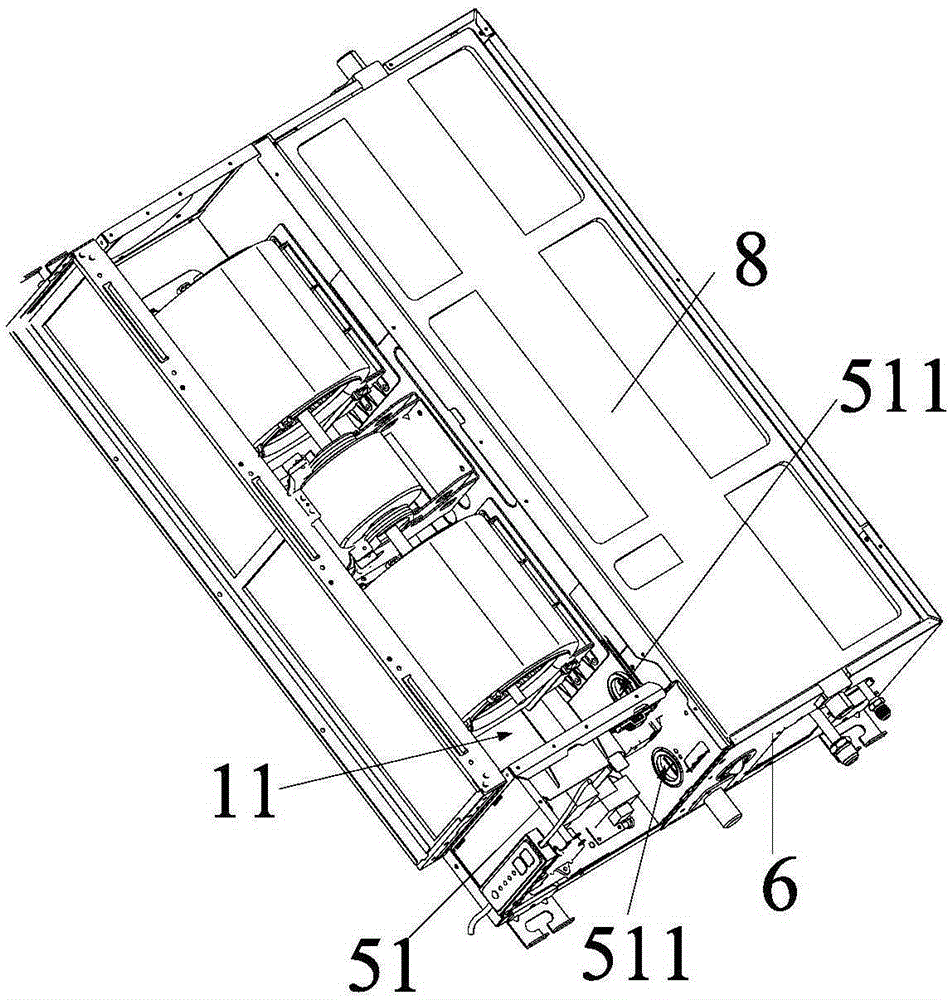

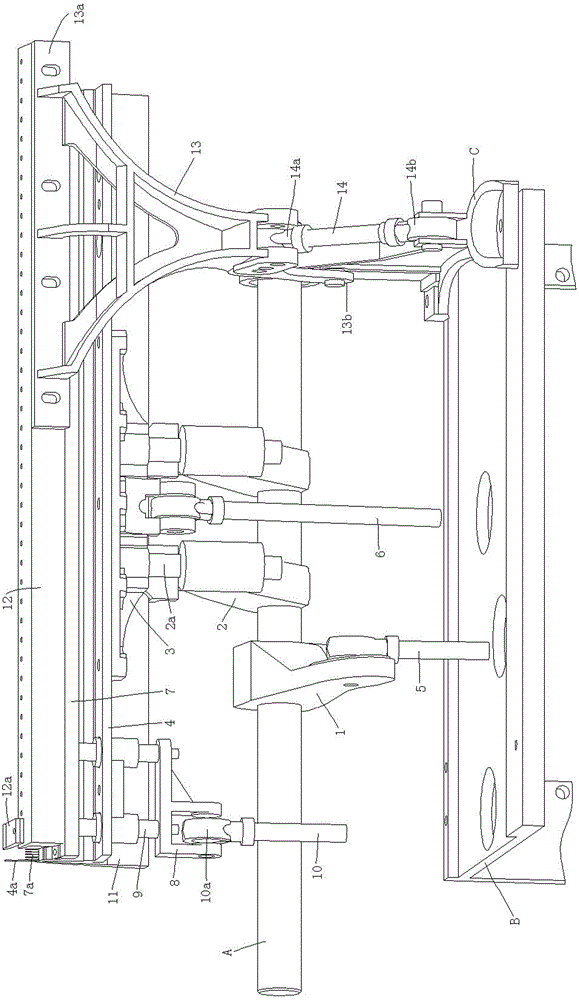

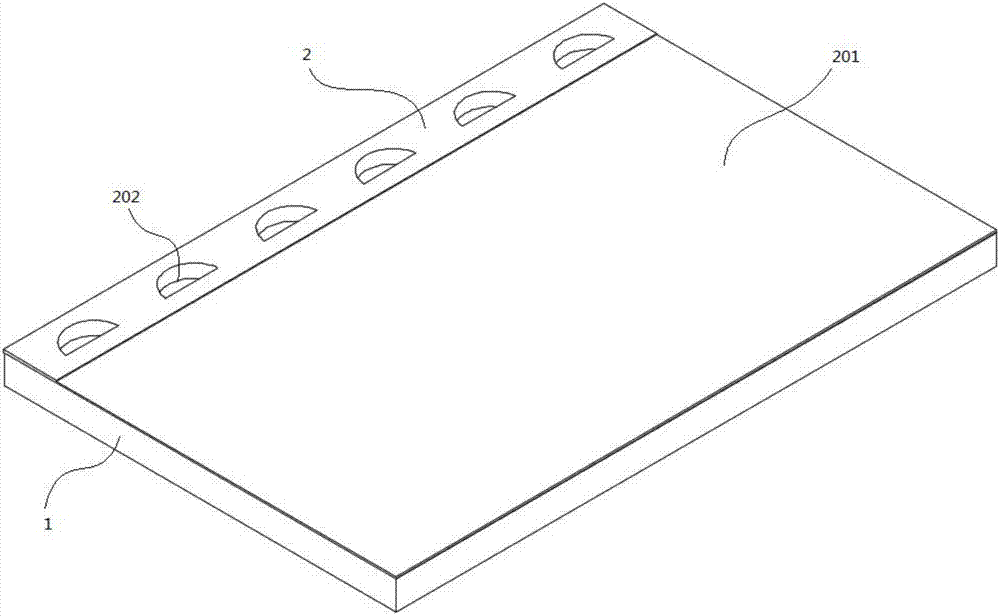

Solar cell panel based on waterflow heat-absorption cycle

ActiveCN107070398AImprove photoelectric heat conversion efficiencySimple structureSolar heating energySolar heat devicesElectricityCells panel

The invention discloses a solar cell panel based on waterflow heat-absorption cycle. The solar cell panel comprises a base, a reflector, a coiled pipe, a cover plate and a substrate; a first bump is arranged on the base; the reflector is fixed on the surface in the base; a plurality of protrusion surfaces are arranged on one surface of the reflector in a row; the coiled pipe is fixed on the reflector through the substrate; a solar cell is fixed on one surface of the substrate; a plurality of studs are arranged on the other surface of the substrate; a second bump is arranged on one surface of the cover plate; the cover plate is provided with a transparent plate; and the second bump and the first bump are relatively matched. By means of the solar cell panel based on waterflow heat-absorption cycle disclosed by the invention, the solar cell and the coiled water pipe are matched, so that a device capable of generating electricity and heating water simultaneously is formed; the substrate is arranged, and used for installing the solar cell and the coiled pipe; the assembly manner among structures is reduced; the installation and maintenance efficiency is increased; while the cell panel is separated by the reflector with the convexity, light irradiates the surface of the coiled water pipe, and is used for heating the coiled water pipe; and thus, the solar cell panel is reasonable in structure and high in energy utilization rate.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

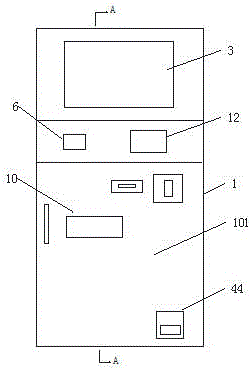

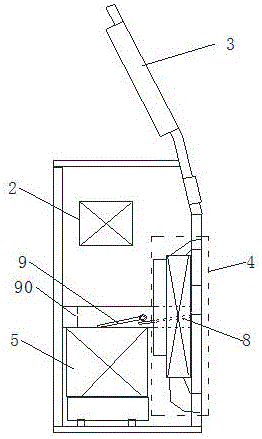

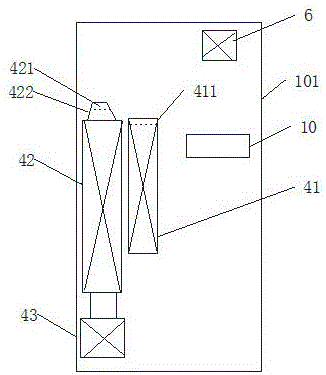

Self-service printing terminal

InactiveCN103996250BPrecise alignmentEasy coin operationApparatus for meter-controlled dispensingTerminal equipmentPulp and paper industry

The invention relates to the field of printers and discloses a self-help printing terminal device. The self-help printing terminal device comprises a cabinet, a control circuit, a touch display screen, a coin inserting device, a printer, an identifying device and a stamping device, wherein the touch display screen, the coin inserting device, the printer, the identifying device and the stamping device are connected with the control circuit. A cabinet paper outlet is formed in the middle of the cabinet. A guide wheel device used for holding the printer is arranged in the cabinet. The touch display screen is installed on the upper portion of a front panel of the cabinet. The coin inserting device comprises a paper currency identifying device and a coin identifying device which are installed on the inner side of a front door sheet of the cabinet. A discharged paper supporting plate which is communicated with the cabinet paper outlet is arranged in front of a printer paper outlet formed in the upper portion of the printer. A printing paper guiding plate is arranged above the inner side of the discharged paper supporting plate and located in front of the printer paper outlet. The identifying device is installed on the front panel of the cabinet. The stamping device is arranged between the printer paper outlet and the cabinet paper outlet. According to the self-help printing terminal device, a coin slot is accurately aligned with a coin inlet of the coin identifying device, discharged paper cannot slide into a gap between the discharged paper supporting plate and the printer, the paper cannot be stuck, the printer is easy to maintain, and the automatic stamping function is achieved.

Owner:上海圣玖机电成套设备制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com