Coil-forming transmission mechanism of warp knitting machine

A transmission mechanism and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the complex processing of the first swing arm and the second swing arm of the needle core mechanism, high manufacturing cost of the needle core spindle, Increase the load of the grooved needle spindle and other issues to achieve the effect of improving work reliability, reducing installation and maintenance time, and improving installation and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

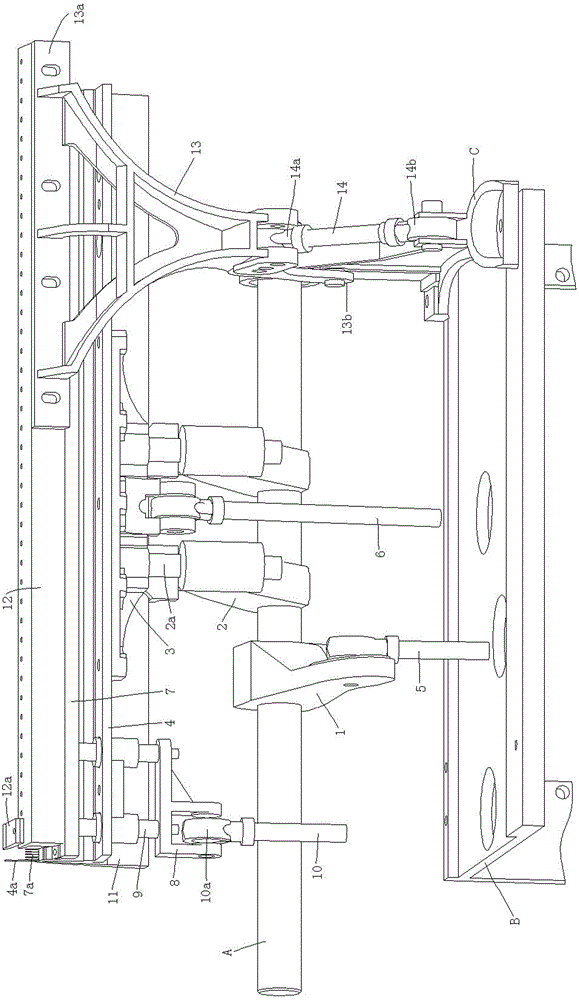

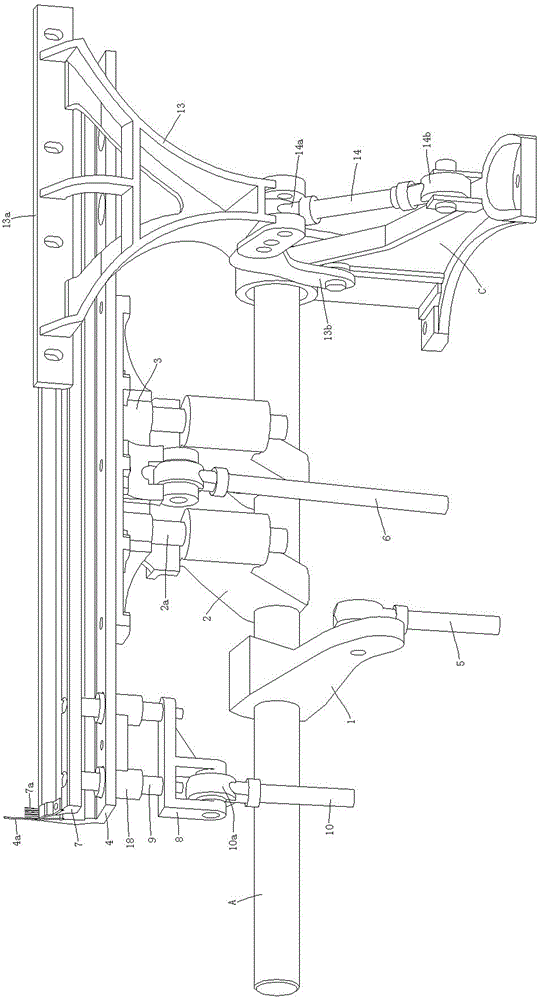

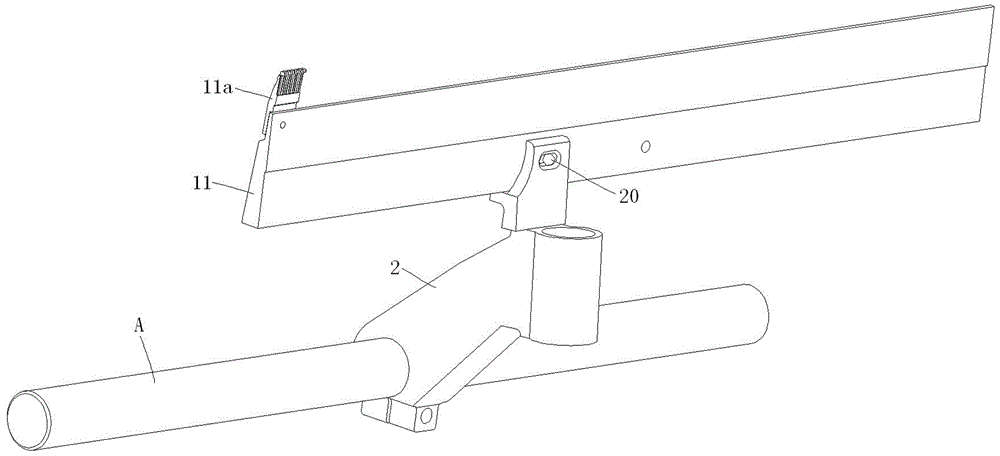

[0024] see Figure 1 to Figure 6 The shown ring-forming transmission mechanism of a warp knitting machine includes a groove needle mechanism, a needle core mechanism, a de-ring mechanism, a settling mechanism, and an oil tank main shaft D rotatably installed in a warp knitting oil tank B through a bearing; the groove The needle mechanism includes a groove needle main shaft A, a groove needle swing arm 1, a guide arm 2, a groove needle bed bracket 3, a groove needle bed 4 installed with a groove needle 4a, and a groove needle linkage mechanism, and the groove needle main shaft A passes through the bearing. It is rotatably installed on the main shaft seat C on the upper part of the warp knitting oil tank B, the slotted needle bed bracket 3 is fixedly installed on the lower part of the slotted needle bed 4 by bolts, and the slotted needle linkage mechanism includes a slot needle 4a for swinging. The moving groove needle fuel tank output rod 5 and the connecting rod 6 for the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com