Electrode for LF (ladle furnace) refining furnaces

A refining furnace and electrode technology, which is applied in the field of electrodes for LF refining furnaces, can solve problems such as affecting production and breaking electrode joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

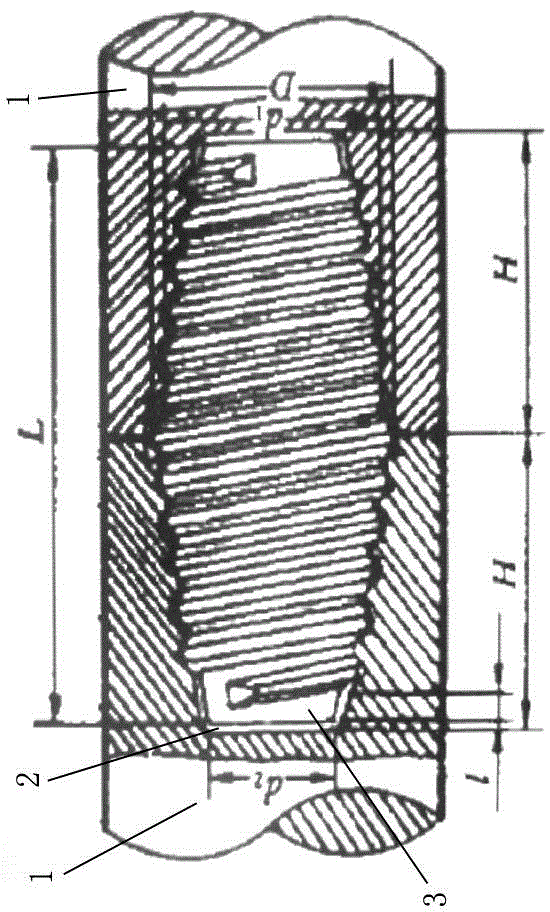

[0018] An electrode for LF refining furnace, as shown in the figure, it includes an electrode body 1 and an electrode joint 3 threadedly connected with it, the nominal diameter of the electrode body 1 is 450 mm, and the electrode joint 3 is a shuttle-shaped rotary body (that is, two ends The diameter is smaller than the diameter of the middle part, and its cross section is circular), the outer surface of the electrode joint 3 is provided with a connecting thread, one end of the electrode body 1 is provided with a joint hole 2 that matches the electrode joint 3, and the inner surface of the joint hole 2 The side is provided with an internal thread. In the electrode joint 3, the maximum diameter of the electrode joint 3 is divided into two sections in the axial direction, and the two sections of the electrode joint 3 are respectively matched with the joint holes 2 of the two adjacent electrode bodies 1, so as to realize the electrode joint 3 Two adjacent electrode bodies 1 are c...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that the maximum inner diameter D of the joint hole 2 ranges from 273 to 274 mm, and the diameter of one end of the electrode joint 3 is d 1 The range of value is 264~265mm, the diameter of the other end of the electrode connector 3 is d 2 The value range of the length L of the electrode joint 3 is 198-199 mm, and the value range of the length L of the electrode joint 3 is 355-356 mm.

[0023] The electrode joint 3 of this structure can effectively improve its anti-breaking ability, and the electrode joint 3 will break once every five years on average. Compared with the prior art, the fracture frequency of the electrode joint 3 is reduced, thereby ensuring the smooth progress of production. Production costs are also reduced.

Embodiment 3

[0025] The difference between this embodiment and Embodiment 1 is that the maximum inner diameter D of the joint hole 2 is 273.05mm, and the diameter of one end of the electrode joint 3 is d 1 =264.62mm, the diameter of the other end of the electrode joint 3 is d 2 =198.70mm, the length L of the electrode joint 3=355.60mm.

[0026] The electrode joint 3 of this structure effectively improves its anti-breakability, and the electrode joint 3 has not broken after eight years of trial use, thereby ensuring smooth production and reducing production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com