Pipeline liquid exhaust device for flow testing

A technology of flow test and exhaust device, applied in the direction of measurement device, liquid/fluid solid measurement, measurement capacity, etc., can solve the problems of inconvenient installation and repair, inability to meet the requirements of gas elimination, top bending of float lever, etc., and achieve the installation pendulum. The effect of stable placement, convenient connection and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

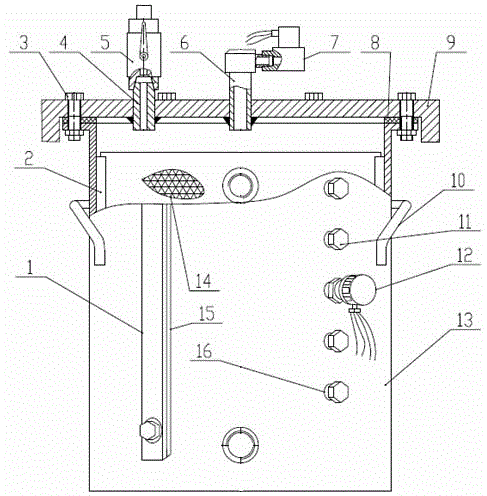

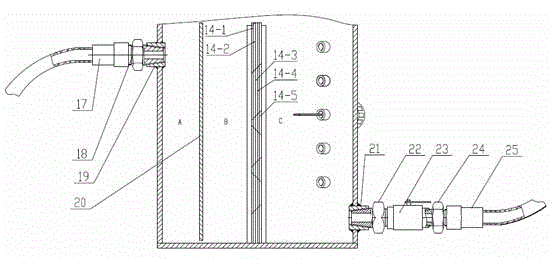

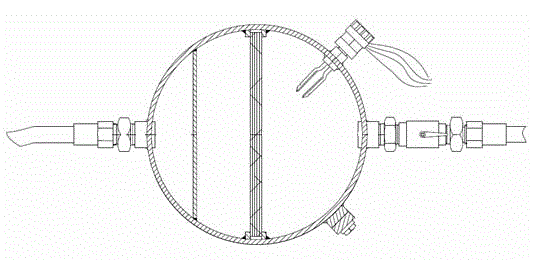

[0024]Referring to the accompanying drawings, this embodiment includes a welded barrel-shaped tank body 13, said tank body 13 is assembled and connected with the top cover 9 through 8 bolt assemblies 3 and a 3mm thick annular oil-resistant rubber sealing backing plate 8, forming a realizable Oil and air-tight container space; the tank body 13 is provided with an inlet screw seat 19 and an outlet screw seat 21, the inlet screw seat 19 and the outlet screw seat 21 are located on the same plane passing through the central axis, and the inlet screw seat The position of 19 is higher than the position of the outlet screw seat 21. The outlet screw seat 21 is vertically welded with a liquid level gauge mounting seat 15 at 45° to the left of the center of the circle. The liquid level gauge mounting seat 15 is equipped with a scale The liquid level gauge 1, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com