Packaging method for organic light-emitting display panel and organic light-emitting display panel

An encapsulation method and a light-emitting display technology, which are applied in the directions of organic semiconductor devices, electrical components, and electric solid-state devices, etc., can solve problems such as difficulty in realizing a narrower frame design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

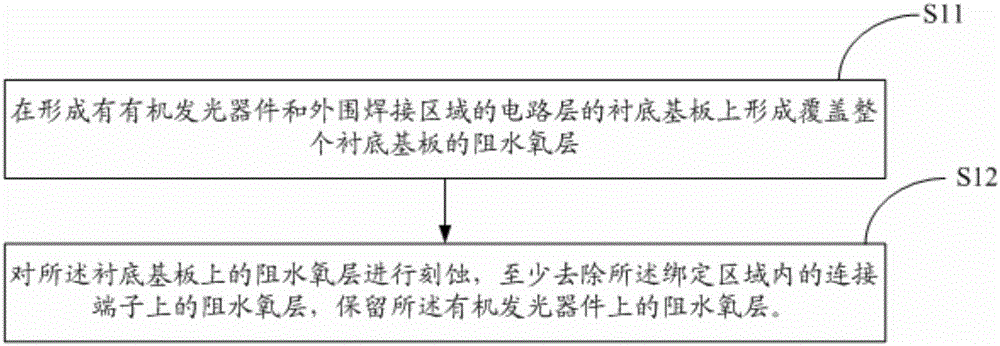

[0042] Method 1: remove all water and oxygen blocking layers in the binding area;

[0043] Method 2: remove the water-blocking oxygen layer on the connection terminals in the binding area, that is, retain the water-blocking oxygen layer outside the connection terminals.

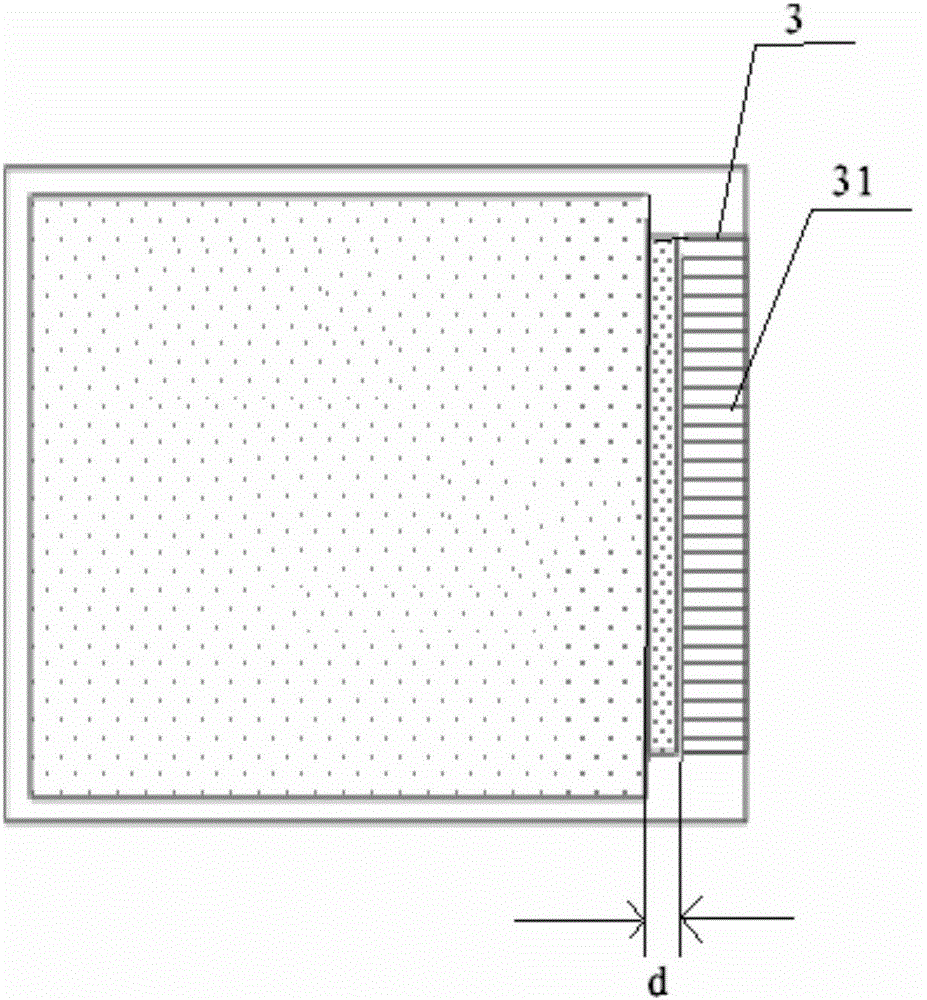

[0044] The size and setting position of the binding area of the organic light-emitting display panel are determined according to actual needs, for example, as figure 2 As shown, the size of the binding area 3 of the organic light emitting display panel may be equivalent to the area covered by the connection terminal 31 . The binding area 3 is located at an area extending a certain distance from the edge of the substrate to the center.

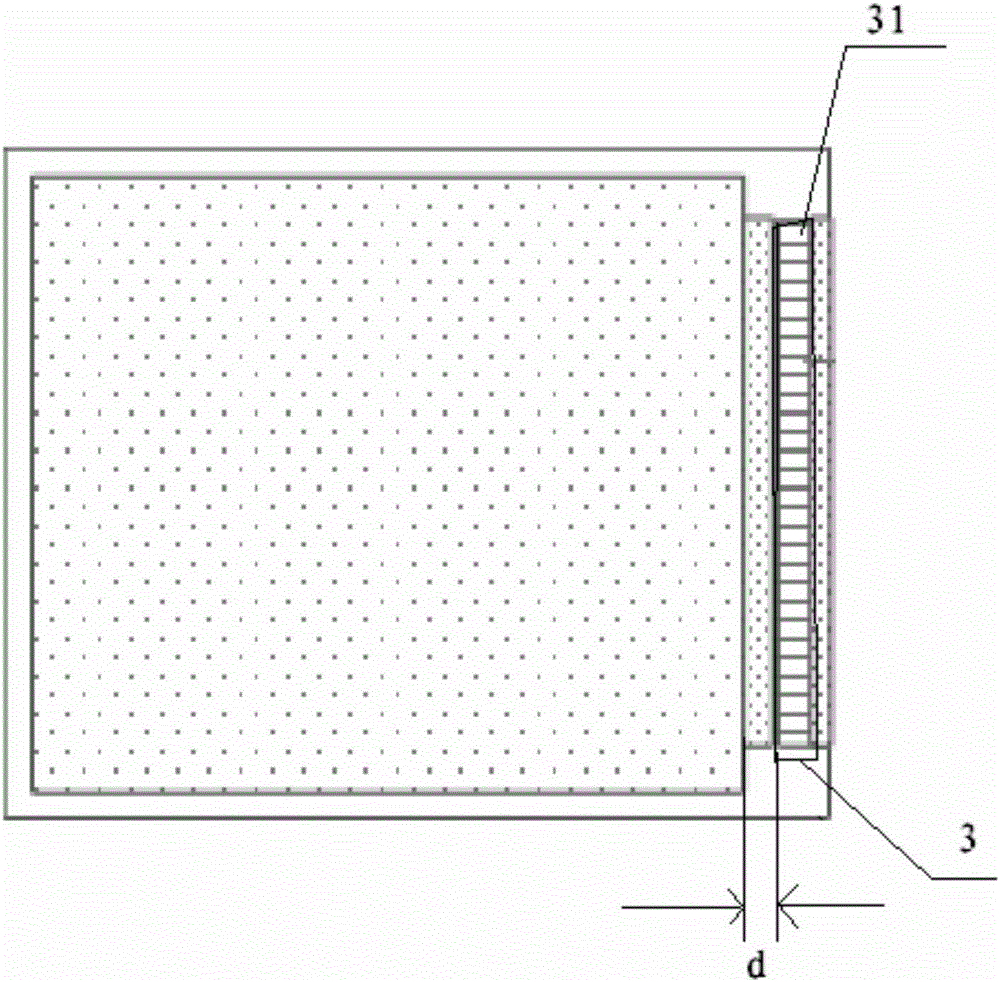

[0045] Such as image 3 As shown, the binding area 3 of the organic light emitting display panel is smaller than the area covered by the connecting terminal 31, and the binding area is a set distance away from the edge of the substrate.

[0046] In the specific implement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com