Permanent magnet DC linear flexible drive

A flexible driver and permanent magnet technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of good motion controllability, small mass and volume, and good motion flexibility, and achieve simple process, small overall volume, and good motion flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

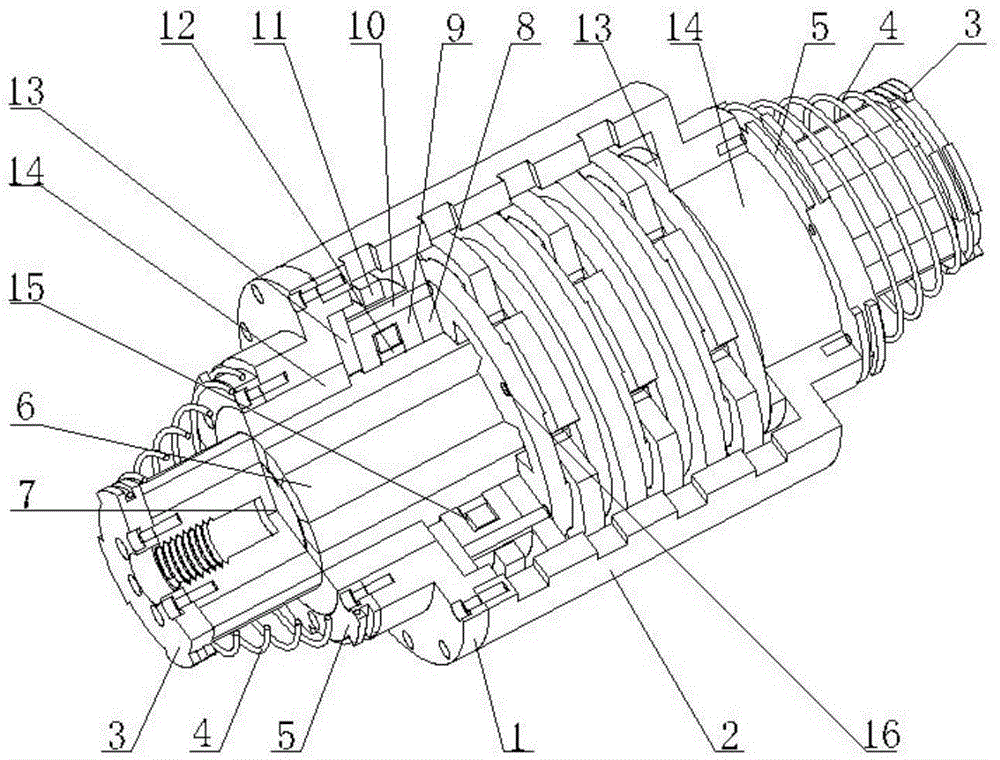

[0035] see figure 1 , Figure 6a and Figure 6b , the structural form of the permanent magnet DC linear flexible driver in this embodiment is:

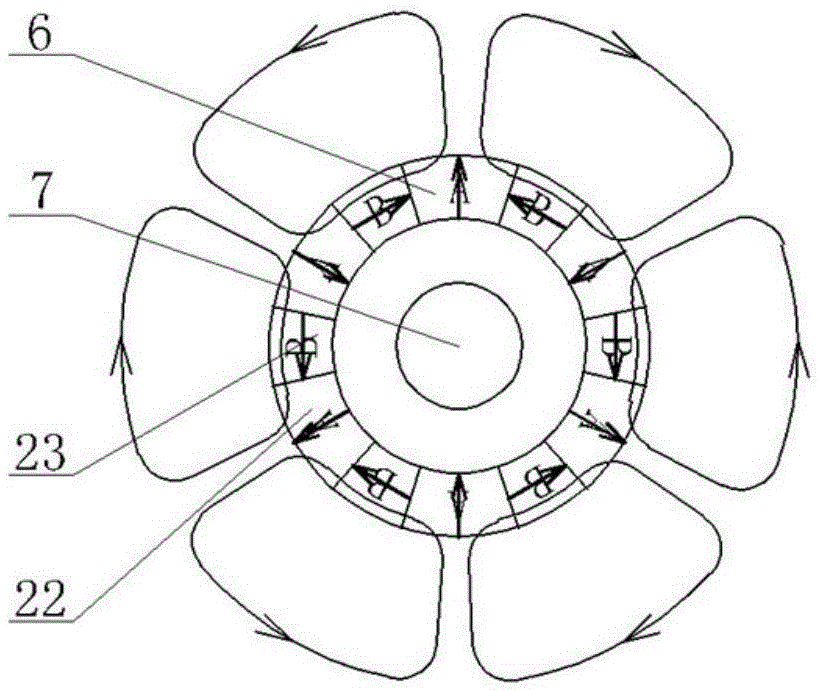

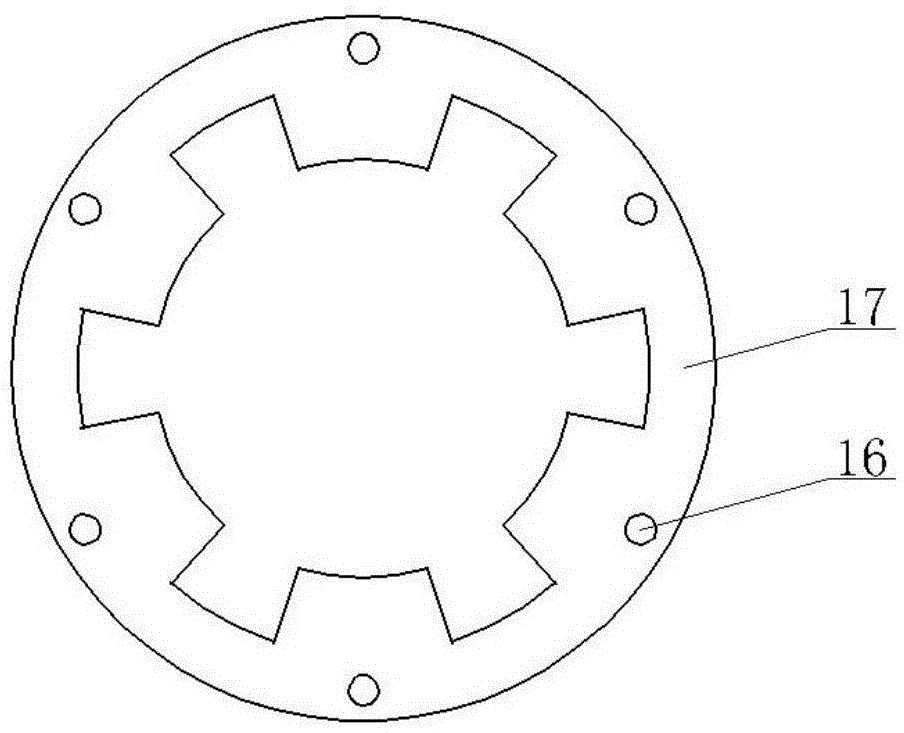

[0036] The mover is composed of a magnetic steel support shaft 7 and a magnetic steel 6 fixedly sleeved on the magnetic steel support shaft 7. The magnetic steel 6 is bonded to the magnetic steel support shaft 7 with superglue, and its structure is simple. The two ends are respectively provided with mover end covers 3; the stator in the form of a cylinder is composed of the stator yoke 9, the stator winding 11, the winding wedge 12, the positioning rod 10 and the positioning ring 8; 1 and the housing 2 constitute a cylindrical shell, and support end caps 5 are respectively provided at both ends of the cylindrical shell; a buffer spring 4 is arranged between the support end cap 5 and the mover end cap 3 to form a buffer limit structure, which plays a role in The function of buffer protection and limit position; the linear bearing 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com