Self-adaptive fixture for laser chip

An adaptive, chip technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of loose chips, easy blockage of vacuum holes, affecting processing efficiency, etc., to eliminate force fluctuations, correct adverse effects, and improve consistency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

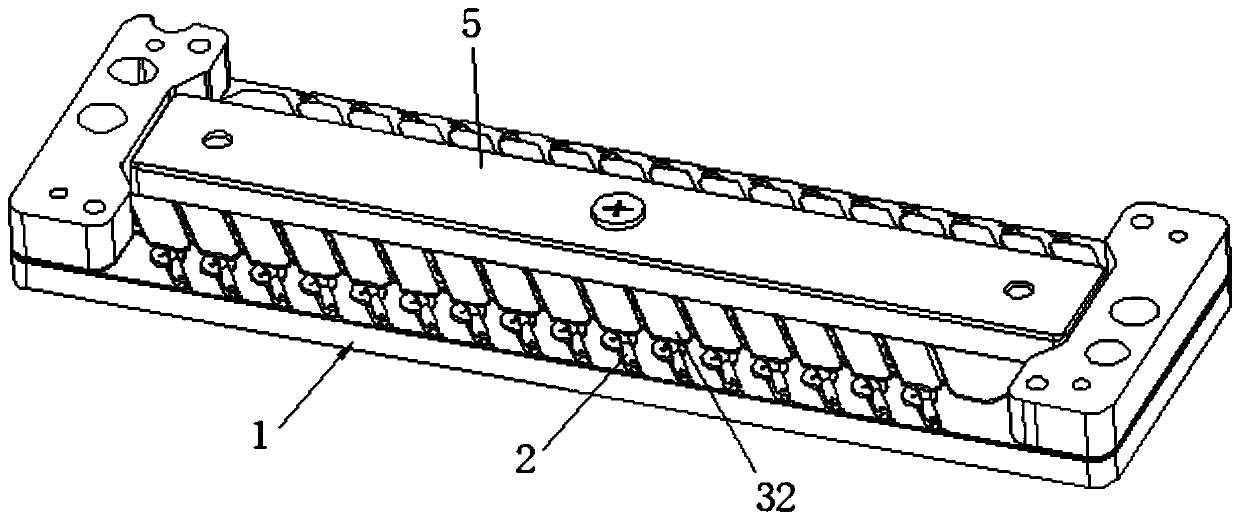

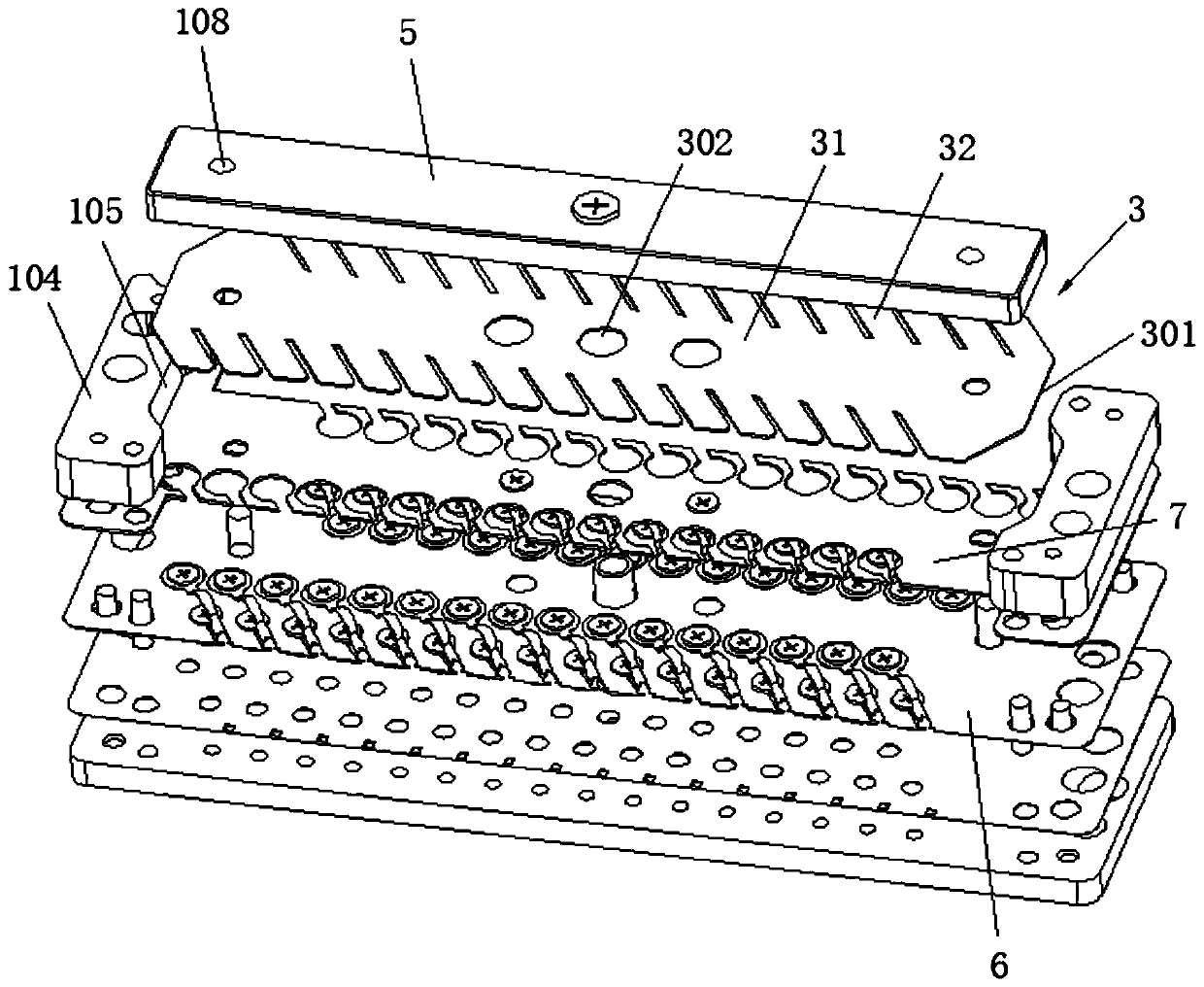

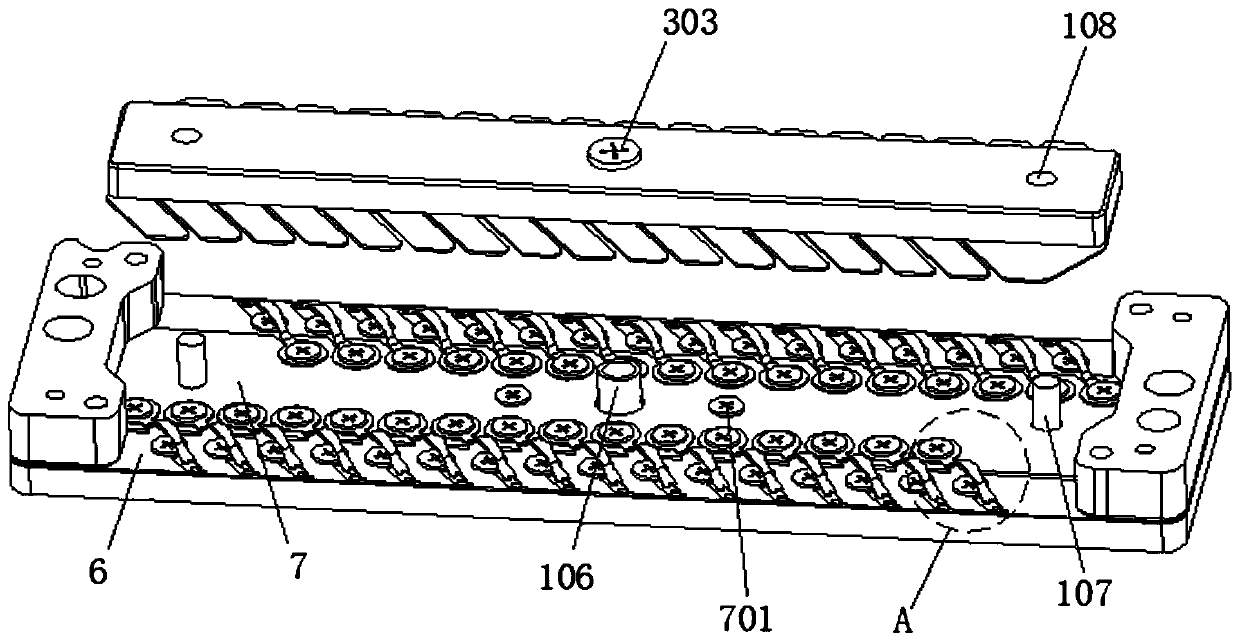

[0030] Embodiment 1: A self-adaptive fixture for a laser chip, referring to the attached Figure 1-4 , comprising a base 1, an elastic piece 2 mounted on the base 1 and a pressing plate 3 above the elastic piece 2, the base 1 is provided with a positioning groove 4 for inserting the chip 8;

[0031]The elastic piece 2 includes a connecting portion 21 installed on the base 1, a deformation portion 22 bent toward the pressure plate 3, and a positioning portion 23, the connecting portion 21 and the positioning portion 23 are connected by the deformation portion 22, and the positioning groove 4 There is a positioning right angle 41, the end of the positioning part 23 of the elastic piece 2 is provided with a right angle positioning notch 24, the two sides of the positioning right angle 41 are in contact with the adjacent two sides of the chip 8, the two sides of the right angle positioning notch 24 are in contact with the chip 8 The other two sides are in contact, and the pressure...

Embodiment 2

[0035] Embodiment 2: A kind of self-adaptive fixture for laser chip, refer to attached Figure 1-4 , comprising a base 1, an elastic piece 2 mounted on the base 1 and a pressing plate 3 above the elastic piece 2, the base 1 is provided with a positioning groove 4 for inserting the chip 8;

[0036] The elastic piece 2 includes a connecting portion 21 installed on the base 1, a deformation portion 22 bent toward the pressure plate 3, and a positioning portion 23, the connecting portion 21 and the positioning portion 23 are connected by the deformation portion 22, and the positioning groove 4 There is a positioning right angle 41, the end of the positioning part 23 of the elastic piece 2 is provided with a right angle positioning notch 24, the two sides of the positioning right angle 41 are in contact with the adjacent two sides of the chip 8, the two sides of the right angle positioning notch 24 are in contact with the chip 8 The other two sides are in contact, and the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com