Tape feeder

A belt feeder, the technology of the belt feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

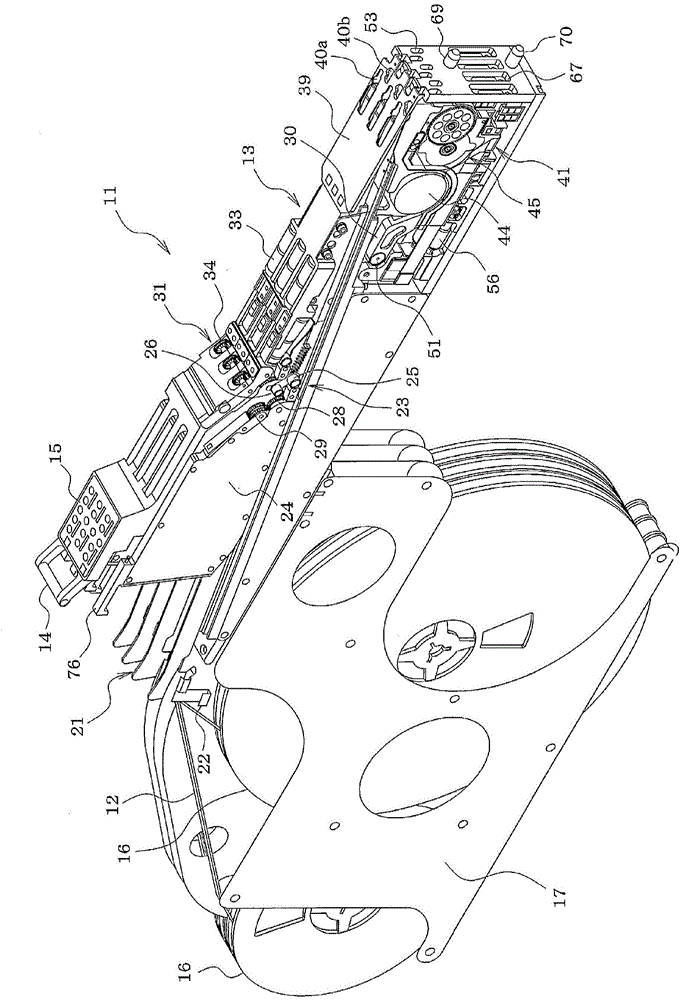

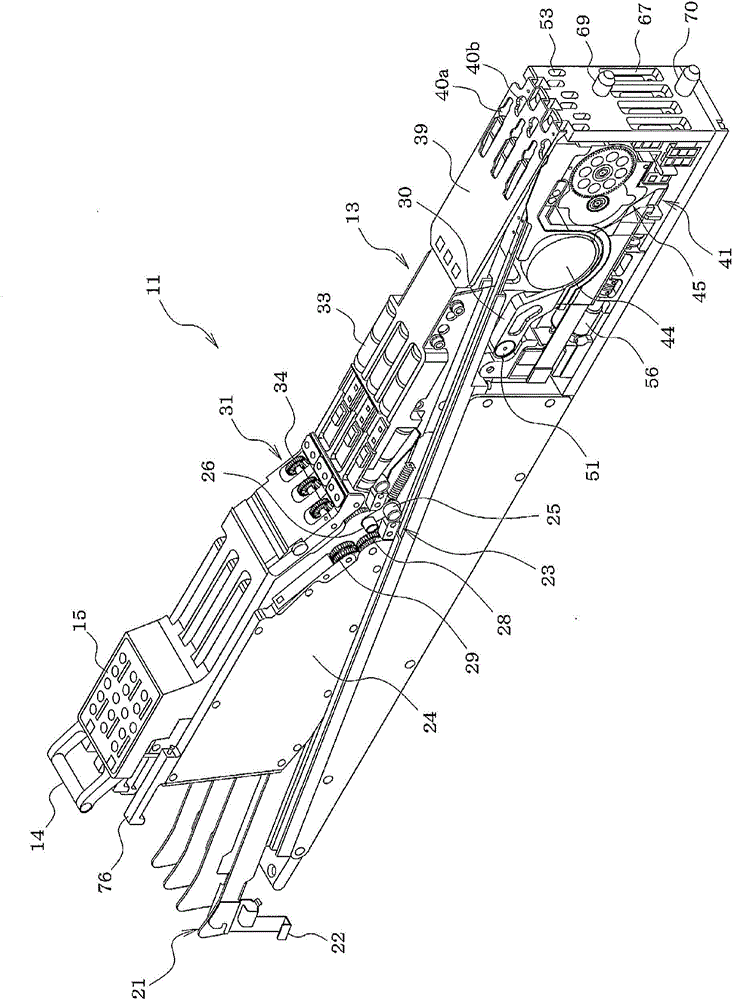

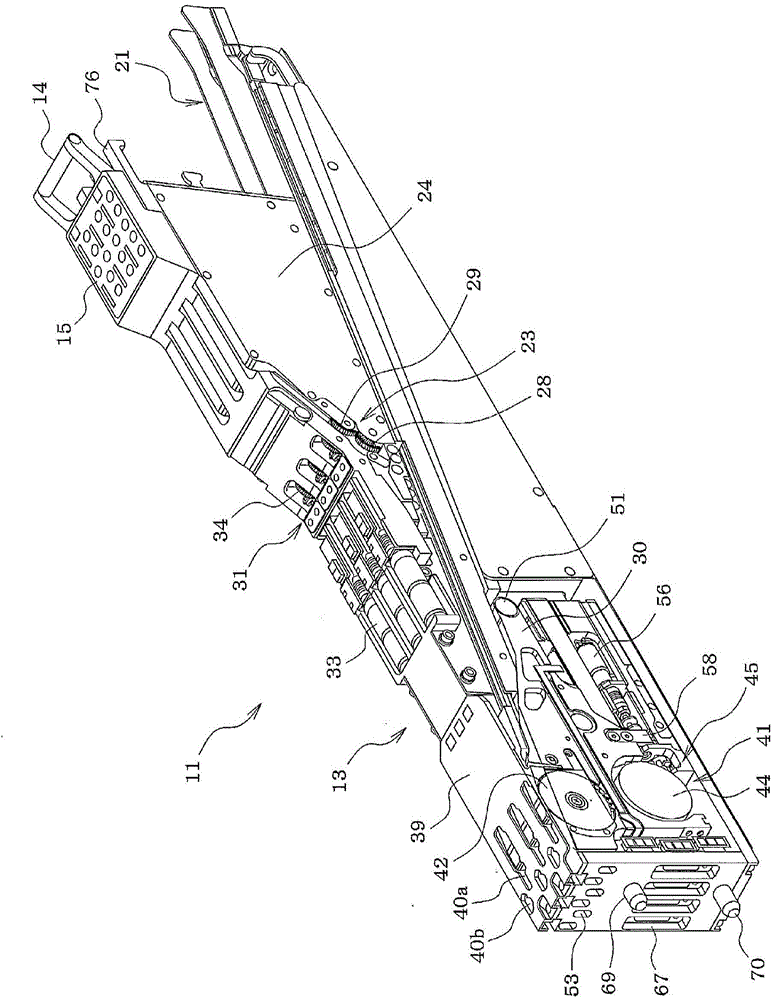

[0036] Hereinafter, one Example of the specific form for implementing this invention is demonstrated using drawing.

[0037] First, the structure of the tape feeder 11 is demonstrated.

[0038]In the tape feeder 11, the width of the feeder main body 13 is approximately the same as that of a conventional general tape feeder (only the multiples of the width of a tape feeder for a component supply tape. In the present embodiment, the width of the feeder main body 13 is made, for example, approximately four times (approximately M times) the width of the conventional general tape feeder by reducing the interval between the adjacent component supply tapes 12 . It is possible to arrange six (N, where N is an integer larger than M) component supply belts 12 in the width direction. Although not shown in detail, the component supply tape 12 accommodates components in component accommodating recesses formed in a line at a predetermined pitch in a carrier tape, and a top tape (also call...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com