Interlocked three-section sliding rail

A slide rail and three-section technology, applied to furniture parts, household appliances, drawers, etc., can solve the problems of easy displacement, disengagement of support sliders, failure of support locks, etc., to improve stability, prolong service life, Ensure the effect of using quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

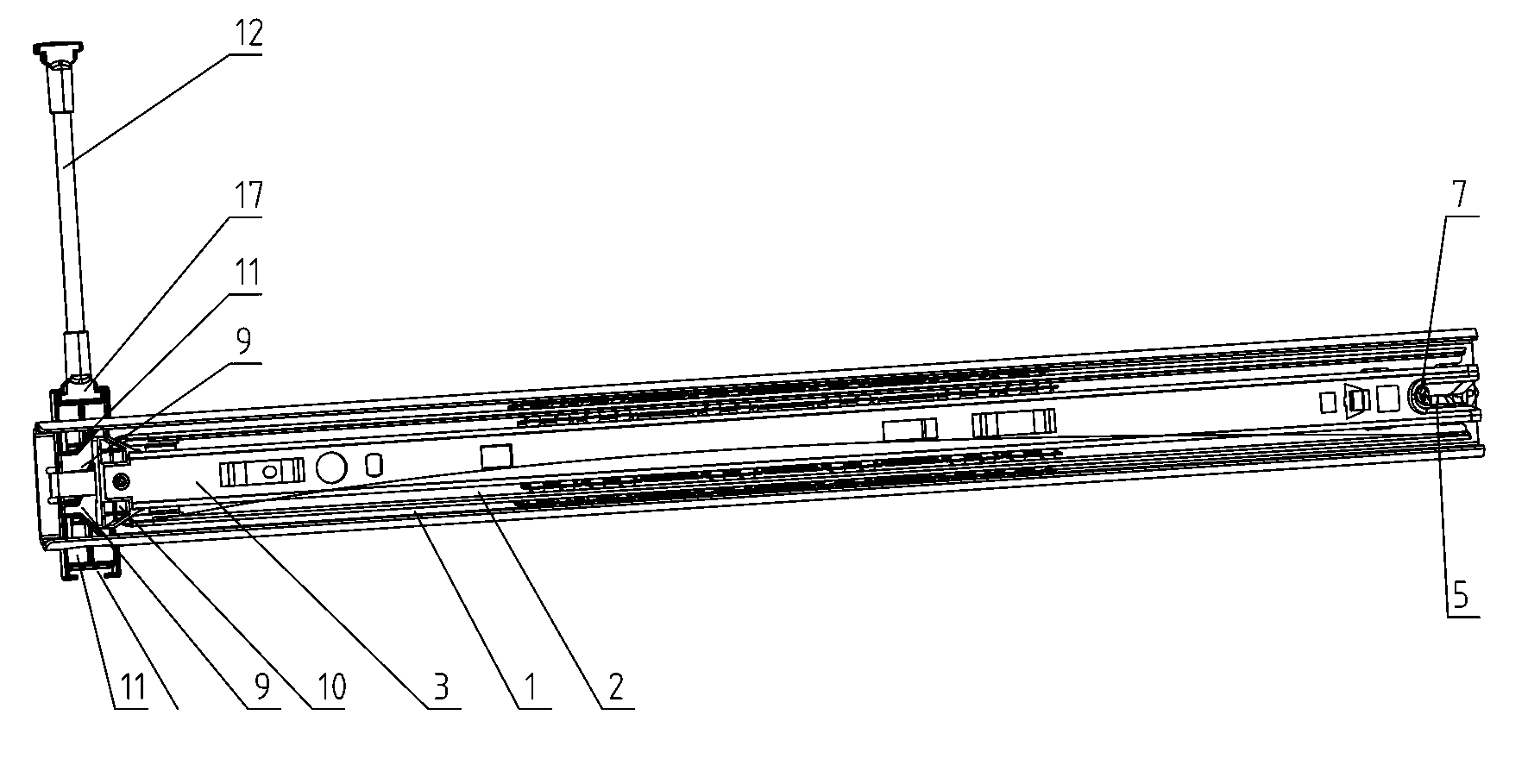

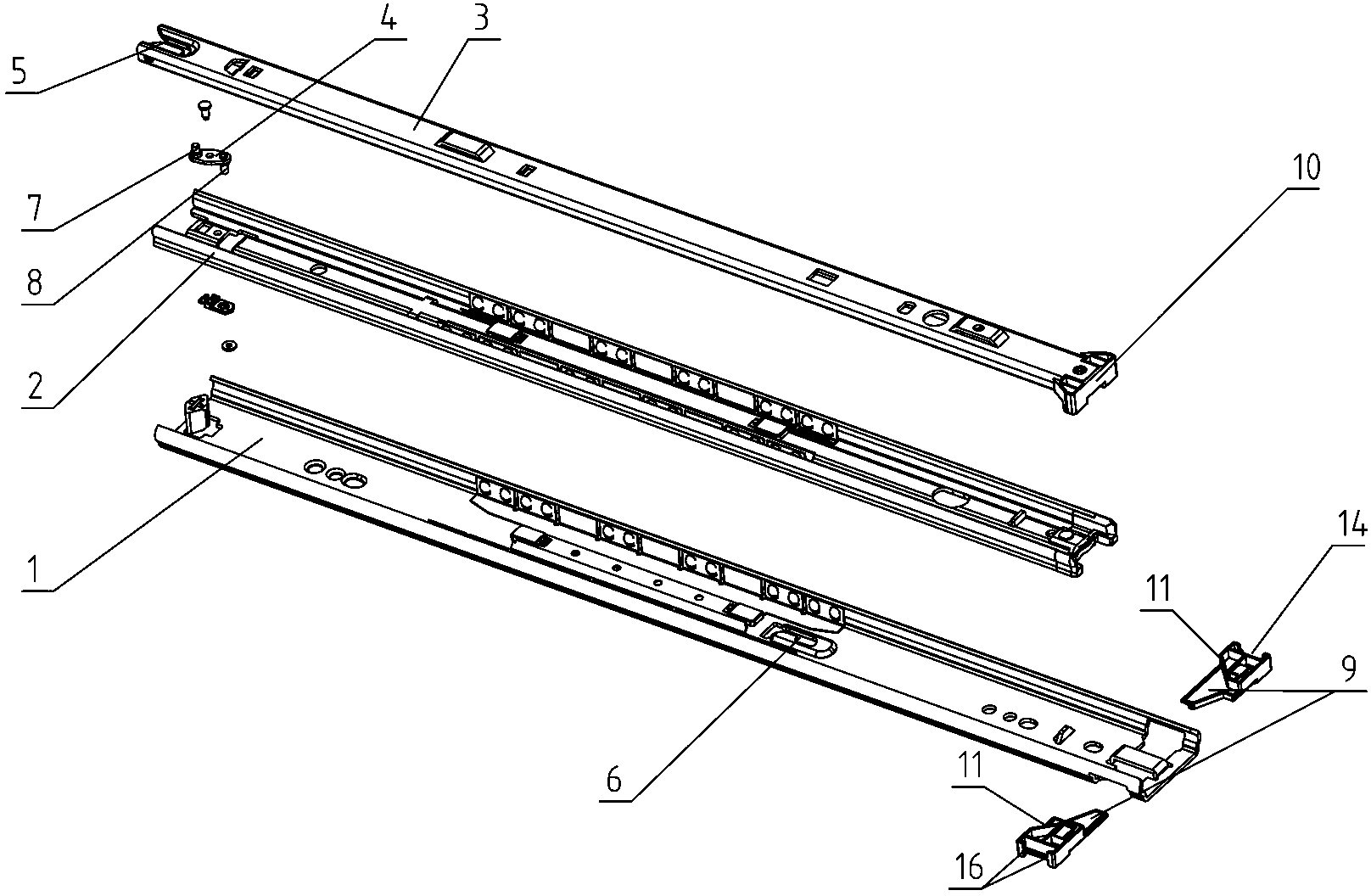

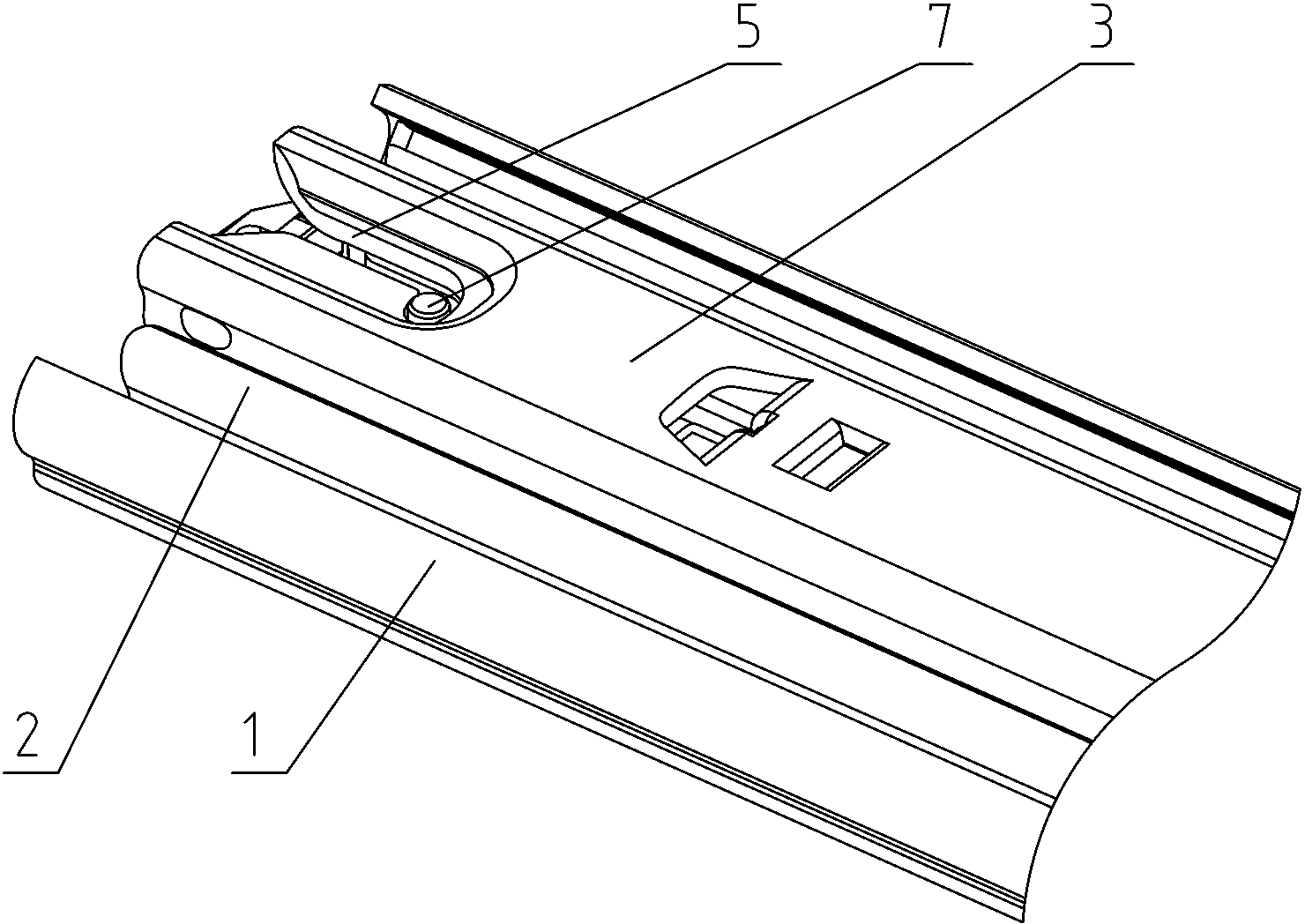

[0023] The present invention will be described in detail below in conjunction with accompanying drawing, as preferred embodiment figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, it includes an outer rail 1, a middle rail 2, and an inner rail 3 that are sequentially embedded and slidably connected. The outer rail 1, the middle rail 2, and the inner rail 3 are respectively equipped with sliding components to ensure running stability. Wherein, the middle rail 2 is provided with a swing buckle 4 capable of swinging left and right and locked on the inner rail 3 or the outer rail 1, the swing buckle 4 is hinged on the middle rail 2, and the inner rail 3 is provided with an adaptive swing buckle 4 Sliding and can the sliding locking groove 5 that swing buckle 4 is buckled usefulness, the outer rail 1 is provided with and swinging buckle 4 connects and swinging buckle 4 breaks away from the sliding locking groove 5 usefulness of sliding locking groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com