A method for manufacturing artificial soft tissue body with vascular network flow channel

A manufacturing method and soft tissue technology, applied in the field of artificial soft tissue preparation, can solve the problems of small repair volume, stent vascularization, insufficient oxygen and nutrient supply for cell growth, etc., and achieve the promotion of vascularization, a wide range of selectivity, and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

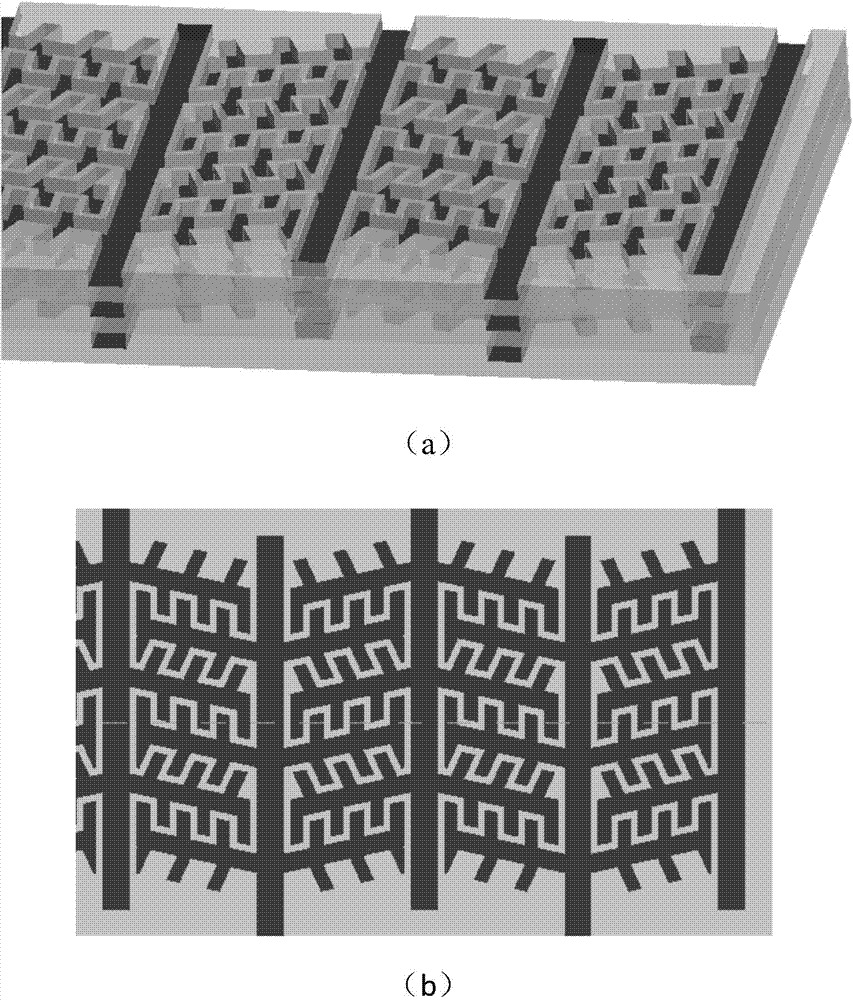

[0028] 1) According to the structure of the arterial vascular network of the organism and the diffusion effect of oxygen and nutrients, use CAD software to design a soft tissue stent model with vascular structure, and layer the designed soft tissue stent model one by one equidistantly, and obtain each layer after layering support, and then respectively manufacture each photomask plate used to manufacture each layer of support;

[0029] The diffusion distance of oxygen and nutrients in the designed soft tissue scaffold model with vascular structure is 200 μm. Considering the hydrogel forming process, the designed blood vessel diameter is 800 μm; the layered thickness of the model is related to the hydrogel forming process and the vascular pore size , the layered thickness of the soft tissue scaffold model is designed to be 800 μm;

[0030] Each photomask is designed and processed according to the structure of each layer of brackets. The specific manufacturing method is: first k...

Embodiment 2

[0041] 1) According to the structure of the arterial vascular network of the organism and the diffusion effect of oxygen and nutrients, use CAD software to design a soft tissue stent model with vascular structure, and layer the designed soft tissue stent model one by one equidistantly, and obtain each layer after layering support, and then respectively manufacture each photomask plate used to manufacture each layer of support;

[0042] The diffusion distance of oxygen and nutrients in the designed soft tissue scaffold model with vascular structure is 200 μm. Considering the hydrogel forming process, the designed blood vessel diameter is 1 mm; the layered thickness of the model is related to the hydrogel forming process and the vascular pore size , the layered thickness of the soft tissue scaffold model is designed to be 1mm;

[0043] Each photomask is designed and processed according to the structure of each layer of brackets. The specific manufacturing method is: first keep t...

Embodiment 3

[0055] 1) According to the structure of the arterial vascular network of the organism and the diffusion effect of oxygen and nutrients, use CAD software to design a soft tissue stent model with vascular structure, and layer the designed soft tissue stent model one by one equidistantly, and obtain each layer after layering support, and then respectively manufacture each photomask plate used to manufacture each layer of support;

[0056] The diffusion distance of oxygen and nutrients in the designed soft tissue scaffold model with vascular structure is 200 μm. Considering the hydrogel forming process, the designed vessel diameter is 900 μm; the layered thickness of the model is related to the hydrogel forming process and the vascular pore size , the layered thickness of the soft tissue scaffold model is designed to be 900 μm;

[0057] Each photomask is designed and processed according to the structure of each layer of brackets. The specific manufacturing method is: first keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com