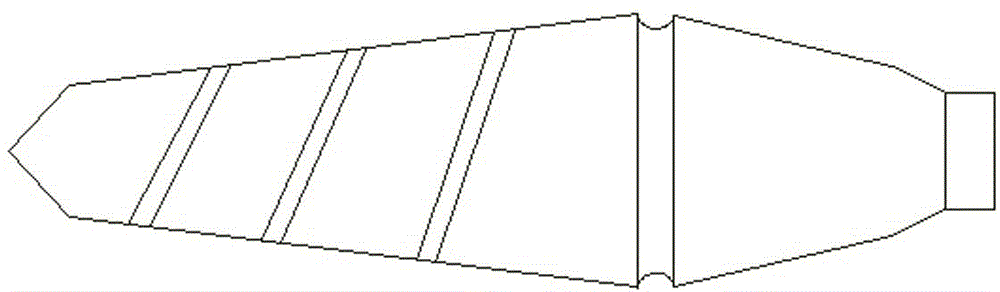

Hard alloy steel taper drill bit

A cemented carbide steel and taper technology, which is used in conical drills, repair drills, drilling tool accessories, etc., can solve the problems of high labor intensity, low processing efficiency, and scrapped workpieces, achieve low labor intensity, and meet the requirements of structural accuracy. High and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The design will be further described below in conjunction with the accompanying drawings of the description.

[0015] A cemented carbide steel tapered drill bit, including a shank and a working part, is characterized in that the working part is tapered.

[0016] further:

[0017] The above described cemented carbide steel taper drill bit is characterized in that: the taper of the taper is 15°.

[0018] The aforementioned cemented carbide steel taper drill bit is characterized in that: the apex angle of the cutting part of the first drill bit is 118°, the bevel angle of the chisel edge is 50°, and the relief angle is 20°.

[0019] The above mentioned cemented carbide steel taper drill bit is characterized in that: the helix angle of the working part is 30°.

[0020] The above-mentioned cemented carbide steel taper drill bit is characterized in that: the material of the cemented carbide steel taper drill bit is cemented carbide steel.

[0021] The above mentioned cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com