Large-curvature curved seam tracking method based on dynamic seam tangent method

A tangent method and large curvature technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of lack of analysis methods, difficulty in establishing mathematical models and control models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

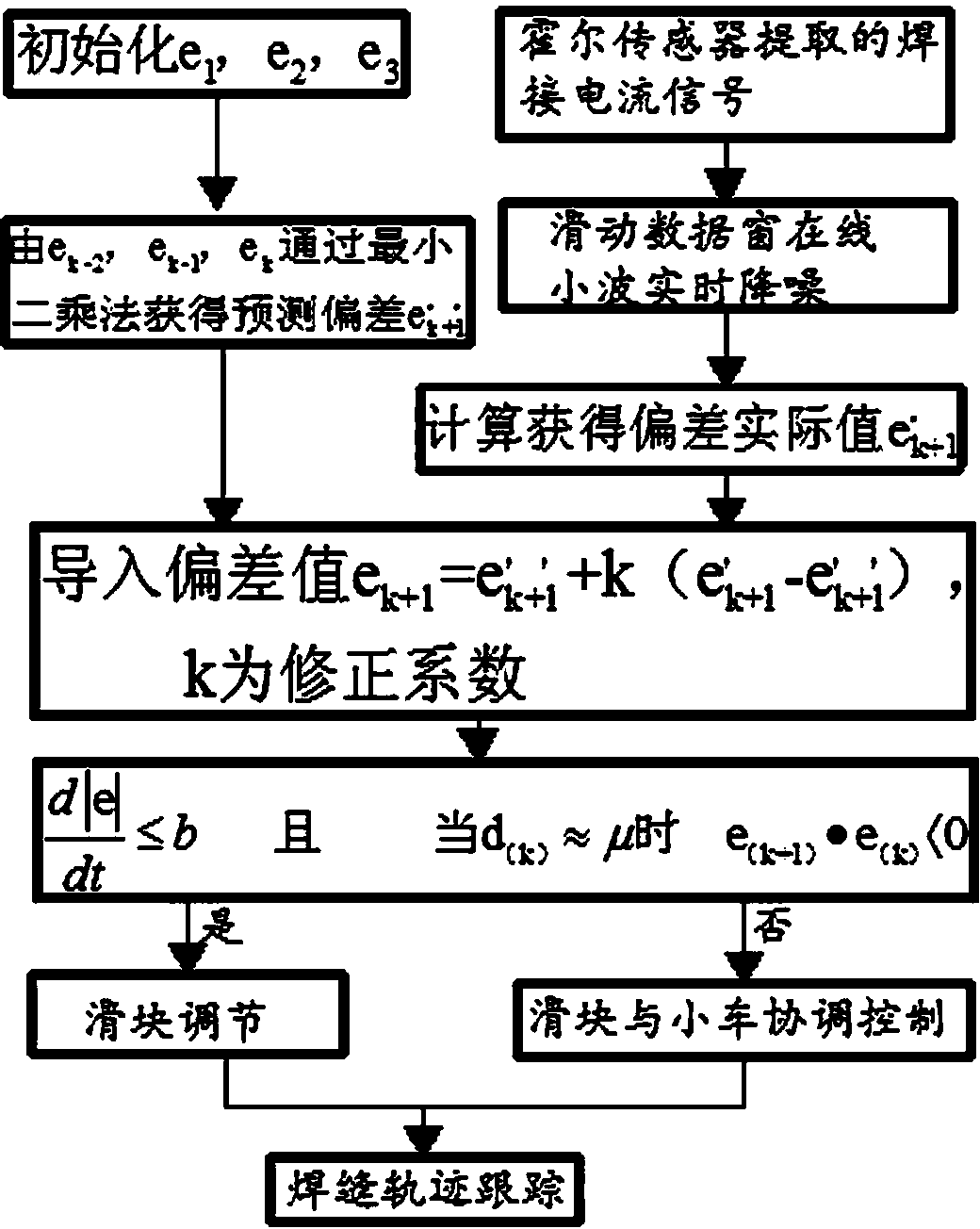

[0030] Embodiment 1, in the seam tracking process at k+1 moment, according to e(k-2), e(k-1), e(k) by least squares method curve fitting, obtain predicted value e"( k+1), then, the arc rotation is controlled by the rotating arc sensor to scan the groove on the weld, the Hall sensor extracts the welding current, and the data acquisition card converts it into a digital signal to calculate the actual weld deviation e' (k+1), use the actual weld deviation value to correct the deviation prediction value to obtain the best weld deviation e(k+1), and finally drive the welding trolley according to the change rate of the best weld deviation and the absolute value of the deviation With the cross slider, the specific implementation is as follows:

[0031] When the moving distance d of the horizontal slider exceeds the set threshold u (the center of the horizontal slider is the reference point), if the sign of the weld deviation is opposite to that of the previous cycle and (|e(k+1)|- |e...

Embodiment 2

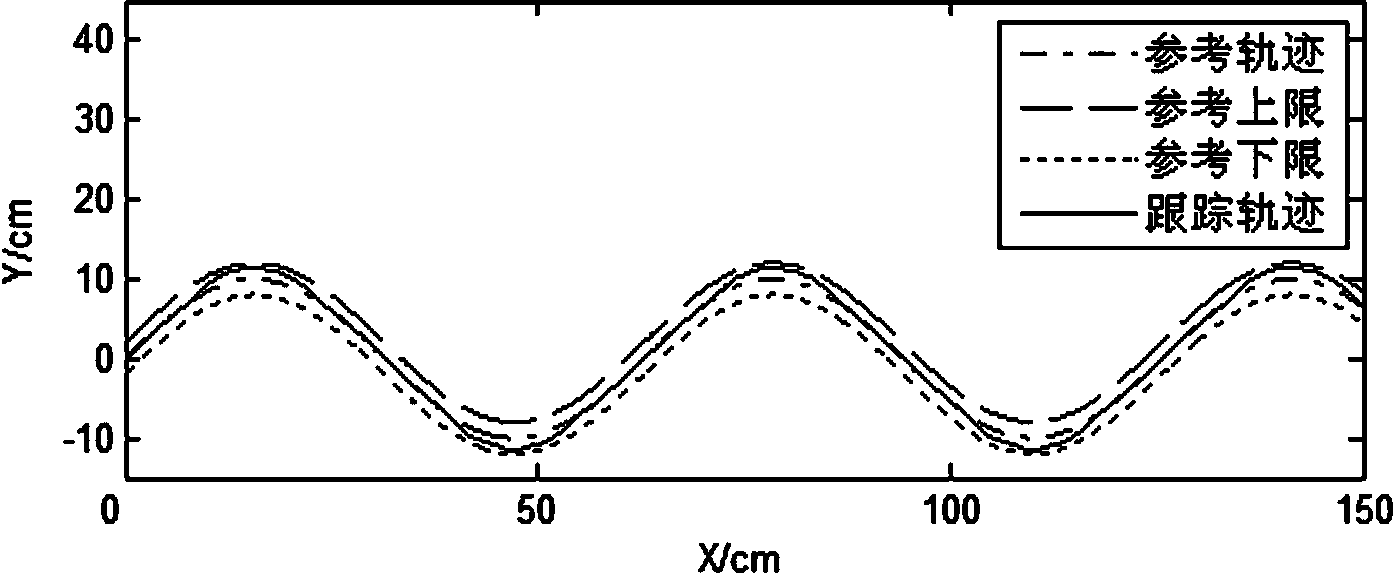

[0046] Embodiment 2, in order to verify the feasibility and superiority of the dynamic weld tangent method model, the simulation analysis using Matlab is as follows:

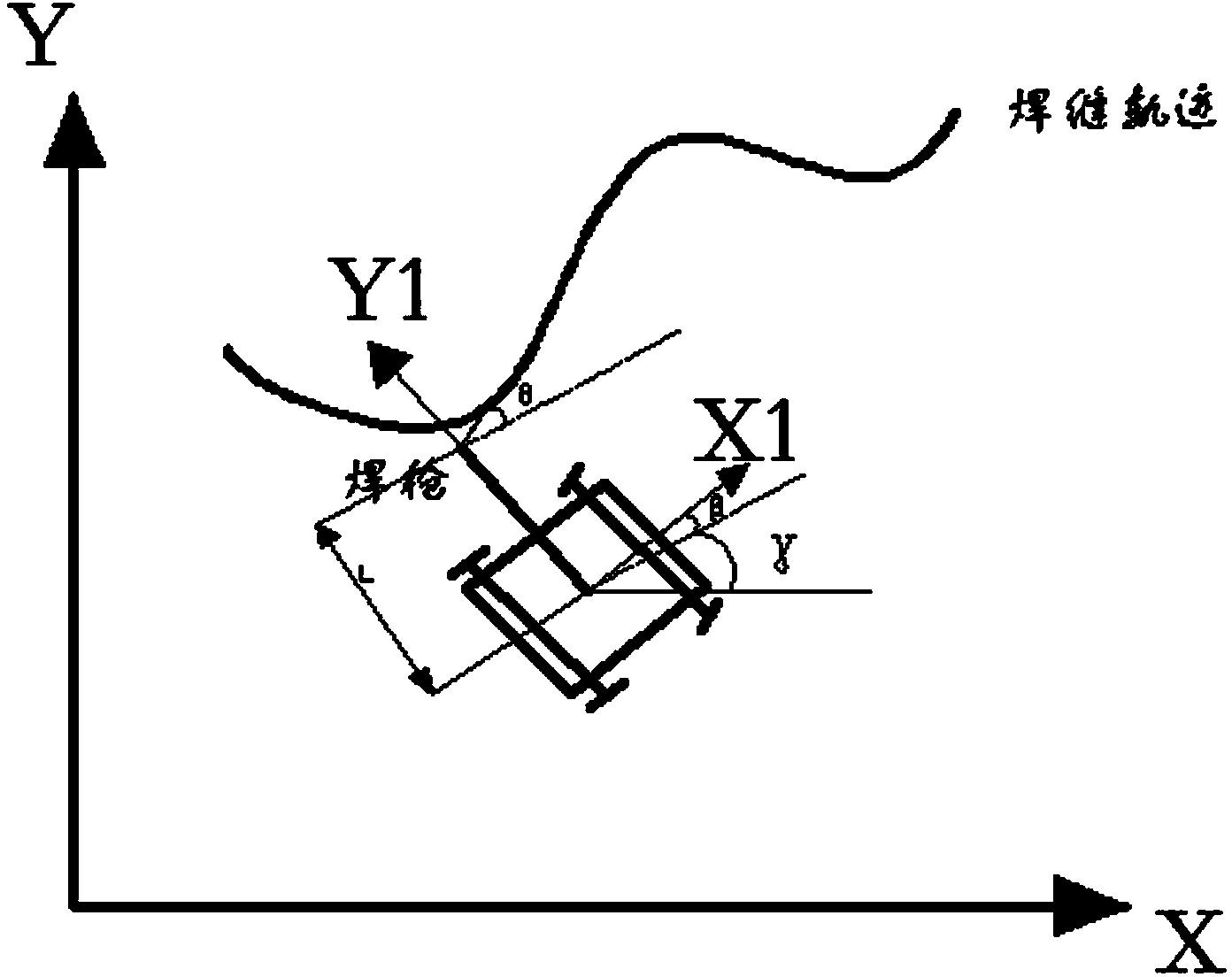

[0047] Simulation condition: v 1 =60cm / min, T=1 / 6s,v 2 =3mm / s, L=30cm. Weld tangent method sampling fourth-order Butterworth filter filtering, delay is set to 0.75s. Dynamic weld tangent method delay can be controlled within 1ms, which can be compared with the sampling period neglect.

[0048] The simulation results are analyzed as follows: image 3 , Figure 4As shown, the weld seam tangent method can basically realize the tracking of the weld trajectory at the small curvature. When the curvature is large, due to the delayed input of the deviation signal, the coordinated control of the welding trolley and the slider is delayed, and the tracking trajectory is obvious. Deviate from the reference trajectory, and the most obvious deviation reaches 1.5cm; and the dynamic weld tangent method solves the delay prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com