Large-scale multifunctional geosynthetic interface dynamic direct shear instrument

A geosynthetic, multi-functional technology, applied in the direction of testing the strength of materials by applying a stable shear force, can solve problems such as difficult research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

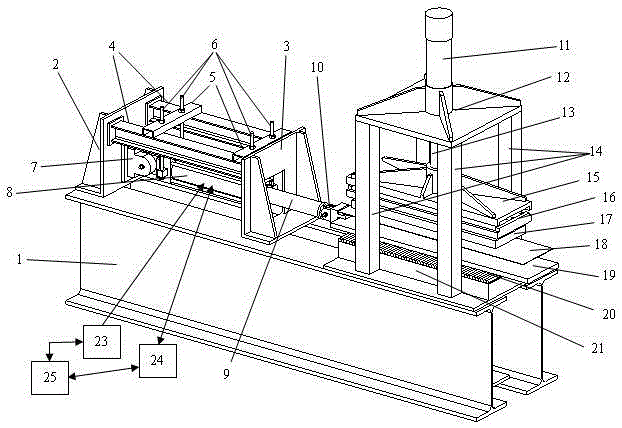

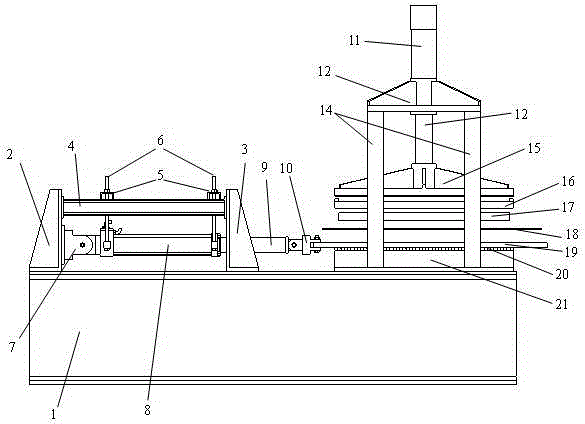

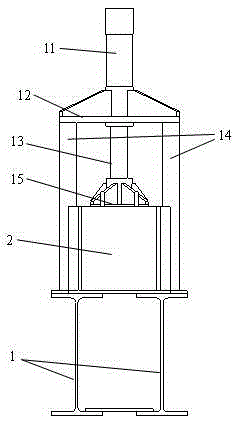

[0029] like Figure 1-Figure 7As shown, the device consists of the instrument base 1, the rear fixing bracket of the vibration exciter 2, the front fixing bracket of the vibration exciter 3, the longitudinal suspension beam 4, the horizontal suspension beam 5, the vibration exciter suspension fixing rod 6, and the vibration exciter fixing support 7 , Exciter cylinder 8, exciter dowel 9, connecting bayonet device 10, vertical press cylinder 11, fixed support top plate 12, vertical press dowel 13, vertical support column 14, loading plate 15. Consisting of lateral limit fixed frame 16, test soil sample 17, test geosynthetic material 18, dynamic extraction plate 19, steel rolling bar group 20, horizontal base 21, second layer test geosynthetic material 22, and vibration exciter Servo system 23, oil pressure delivery control system 24, computer adjustment control system 25. Among them, the instrument base 1 serves as the bottom fixing system of the whole multifunctional test plat...

Embodiment 2

[0035] The device described in Example 1 is used to test the double geosynthetic interface direct shear test mode, and its working process is as follows: a test geosynthetic material 18 with a size of 1250 mm × 350 mm is attached to the upper surface of the dynamic extraction plate 19, and the A test geosynthetic material with a size of 1050mm×350mm is attached to the lower surface of the pressure loading plate 15, and the computer numerical control system 31 and the oil pressure control system 30 are controlled to make the geosynthetic material 22 on the lower surface of the pressure loading plate 15 and the dynamic extraction plate 19 The geosynthetic material 18 on the surface contacts to form a shear plane, and the applied normal pressure continues to increase until it reaches the experimental set value. The extraction plate 19 and the exciter dowel 9 are firmly connected with bolts through the steel dowel fixing device 10, the computer numerical control system 25 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com