IGBT (insulated gate bipolar transistor) module of motor controller and applied motor controller

A technology of motor controller and control board, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of affecting the stability and reliability of equipment, poor cooling effect of motor controller, low degree of modularization of parts, etc., to achieve heat dissipation and cooling Good effect, saving labor cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

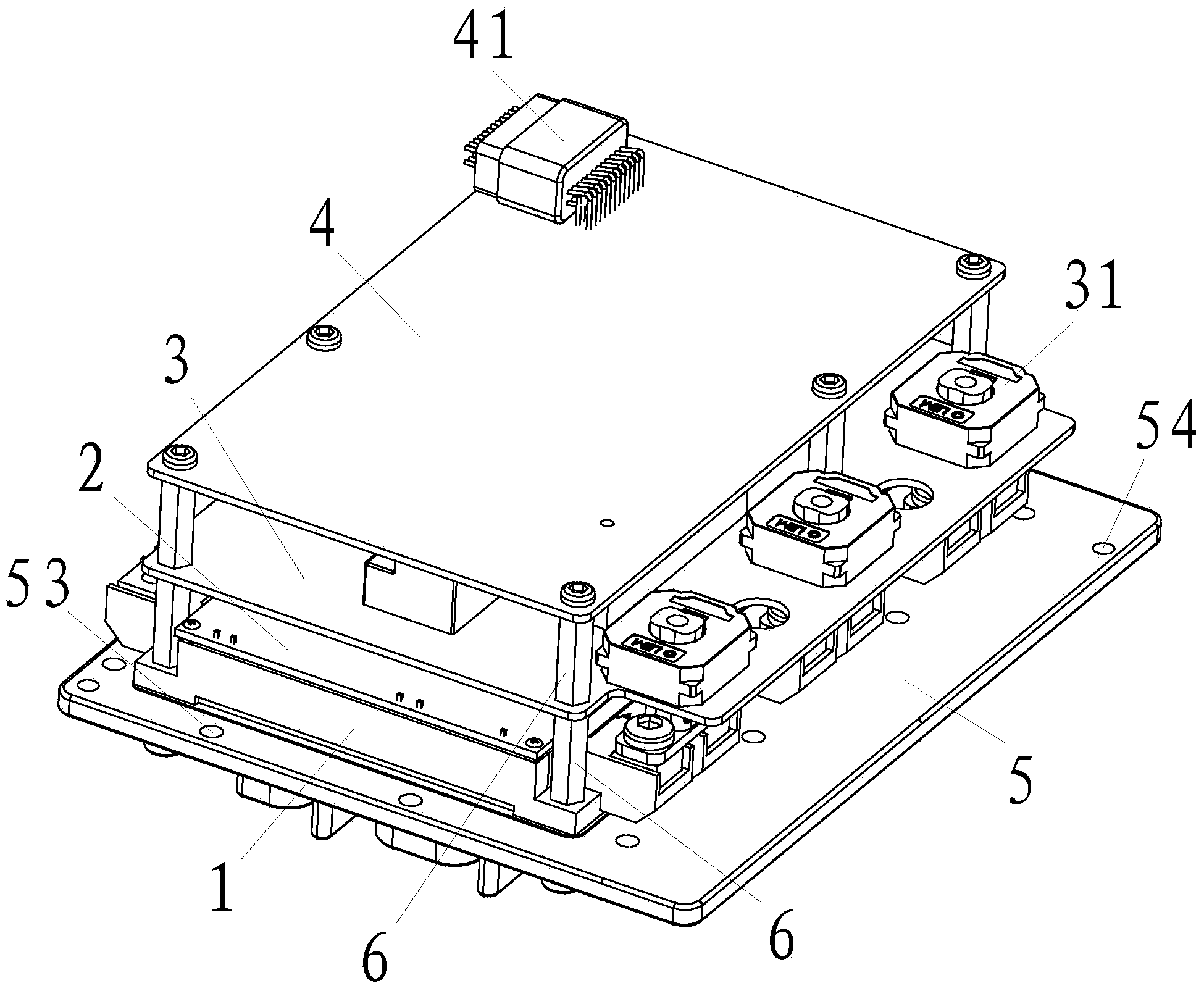

[0037] Embodiment one: if image 3 , Figure 4 and Figure 5 As shown, the present invention is an IGBT module of a motor controller, including an IGBT element 1, a gate plate 2, a drive plate 3 and a control plate 4, the gate plate 2 is installed on the top surface of the IGBT element 1, and the drive plate 3 Installed on the top surface of the gate plate 2, the control board 4 is installed on the top surface of the drive board 3, it also includes a heat dissipation base plate 5, a number of heat dissipation fins 51 protrude downward from the bottom surface of the heat dissipation base plate 5, and the heat dissipation fins A cooling water channel 510 is formed between 51, and the IGBT element 1 is installed on the top surface of the heat dissipation bottom plate 5. This structure is simple, and the degree of modularization is high, and it is convenient to install into the motor controller and form a complete cooling channel. efficient. An annular sealing groove 52 is arra...

Embodiment 2

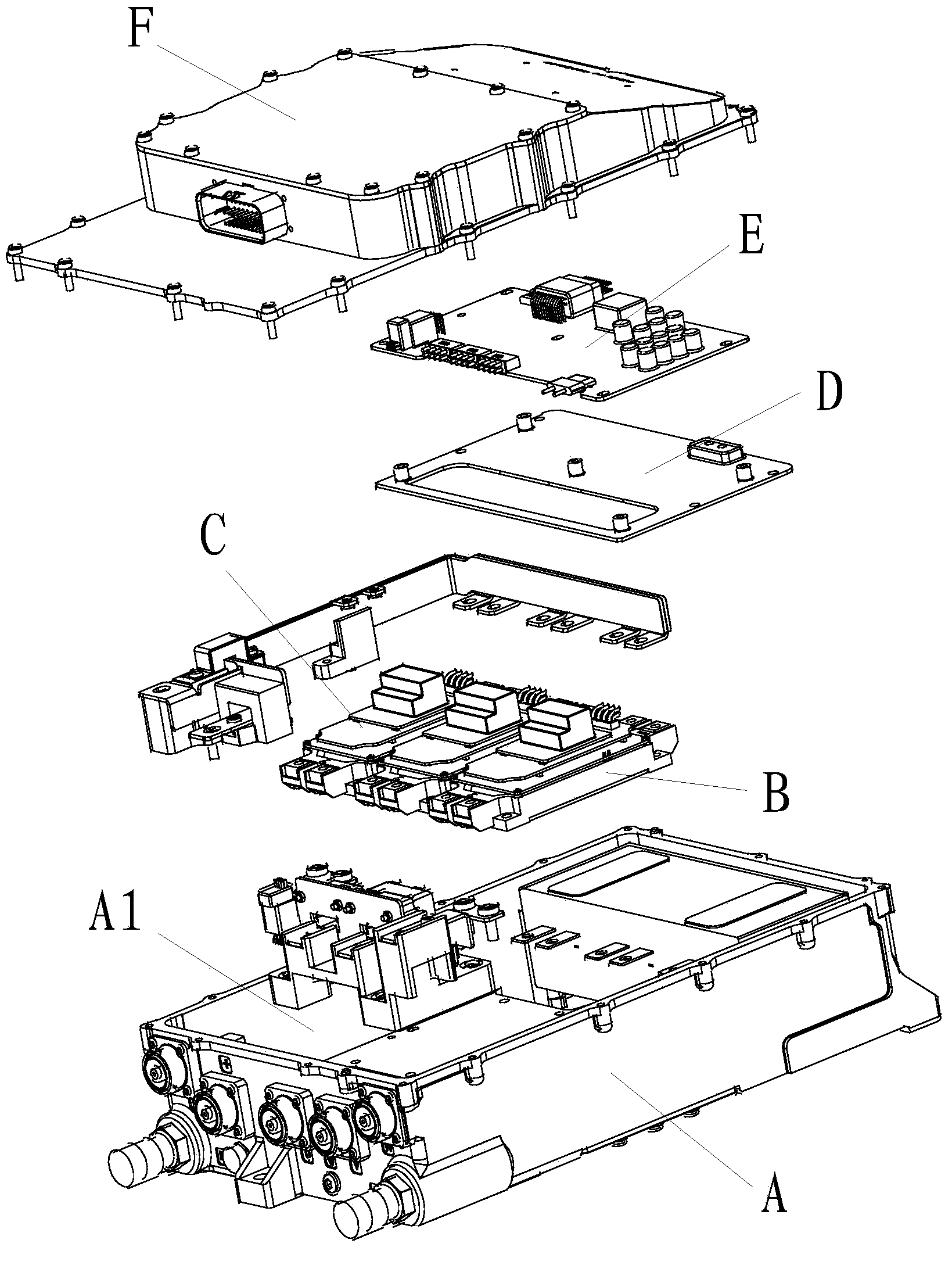

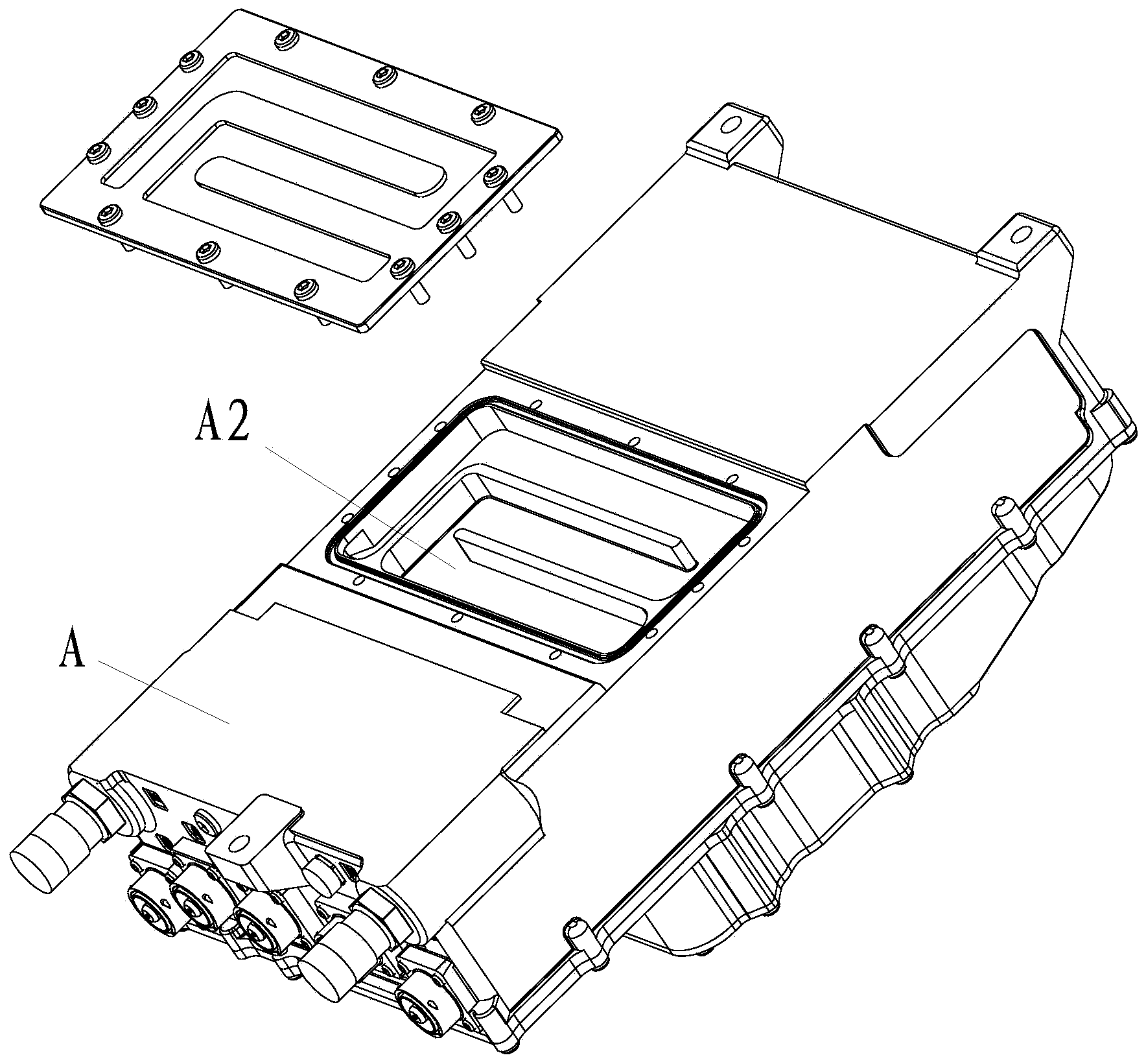

[0038] Embodiment two: if image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the present invention is a motor controller, including a box body 8, an IGBT module 9 and an upper cover assembly 10, a cavity 81 is opened in the middle of the box body 8, the IGBT module 9 is installed in the cavity 81, and the upper cover assembly 10 Installed on the top surface of the box body 8 and covering the opening at the top of the cavity 81, the IGBT module 9 includes an IGBT element 1, a gate plate 2, a drive plate 3 and a control board 4, and the gate plate 2 is installed on the IGBT On the top surface of the component 1, the driving board 3 is installed on the top surface of the gate plate 2, and the control board 4 is installed on the top surface of the driving board 3. It also includes a heat dissipation bottom plate 5, and the bottom surface of the heat dissipation bottom plate 5 extends downward A number of heat dissipation fins 51 are formed, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com