Improved structure for connecting wheel hub and steel wires

A technology of steel wire and hub, applied in the direction of wheels, spoked wheels, vehicle parts, etc., can solve the problems of easy column breakage, reduce efficiency, increase difficulty, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

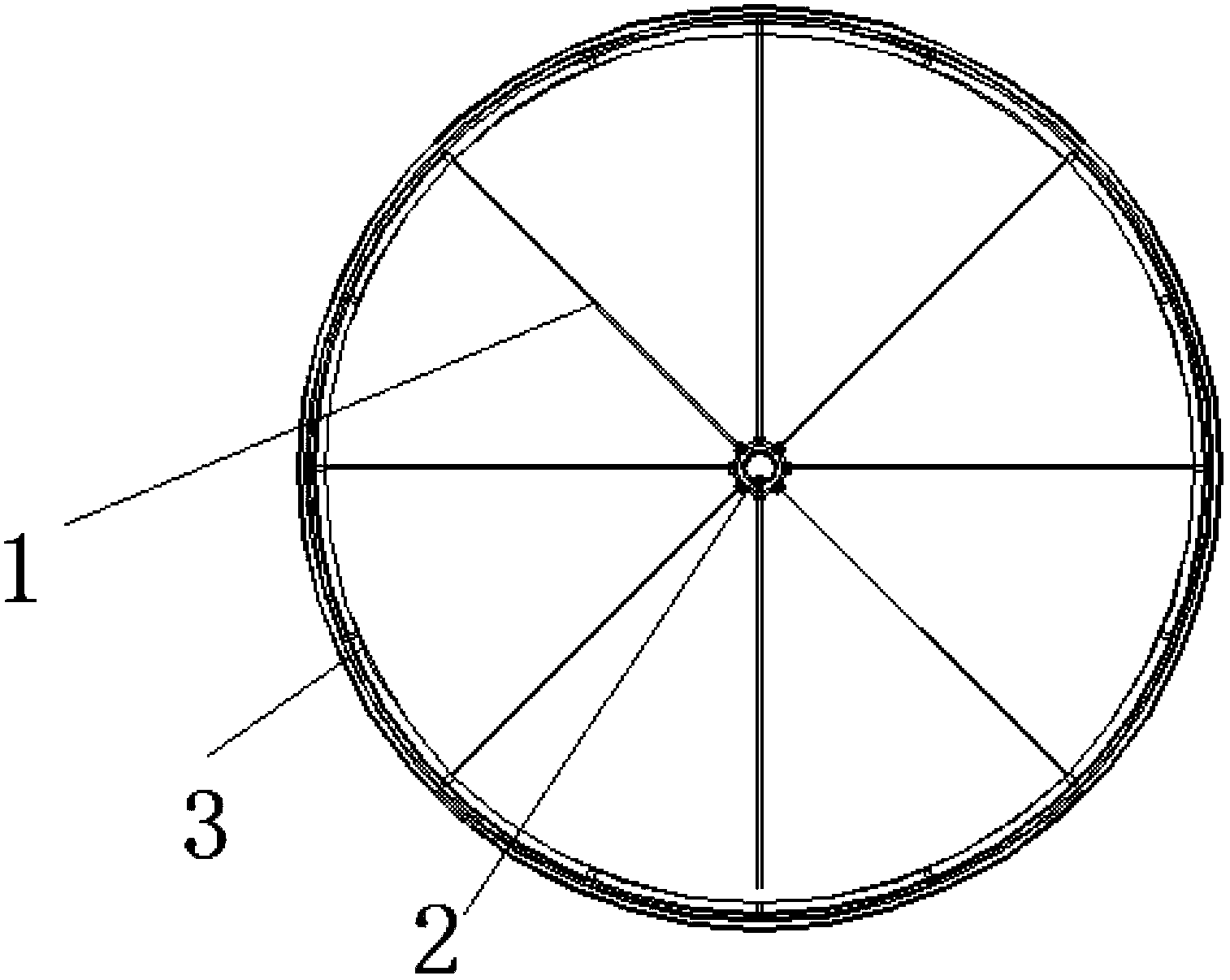

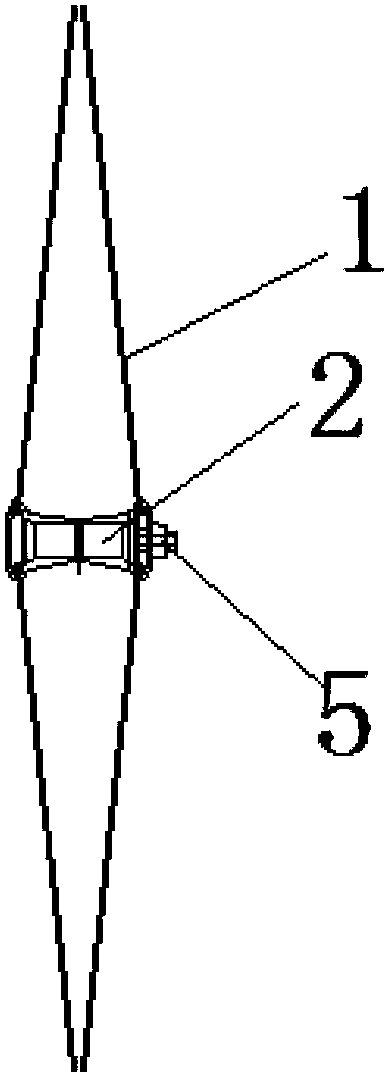

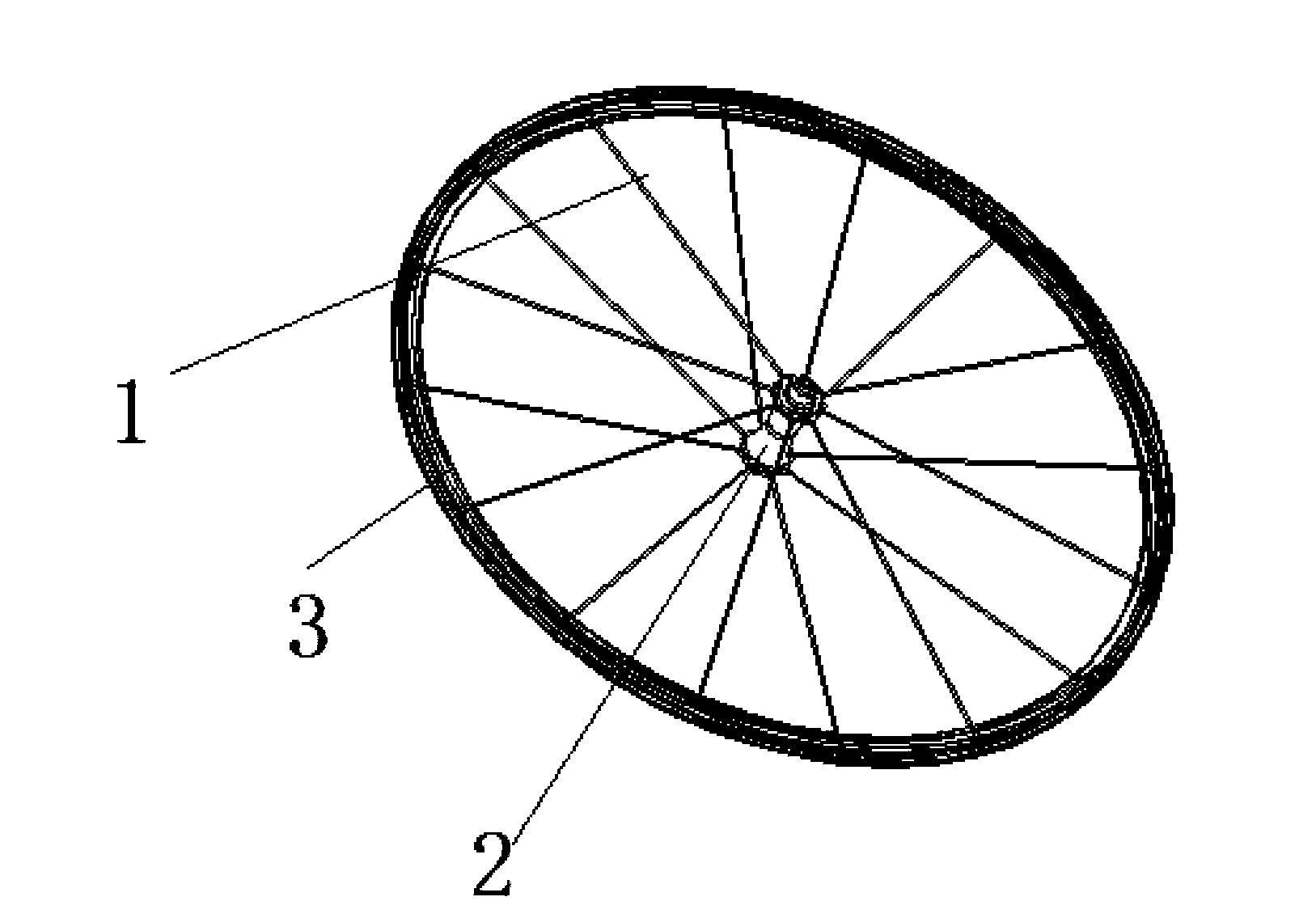

[0020] combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , as described in detail below:

[0021] An improved structure for connecting the hub of a wheel with steel wires, each steel wire on the wheel is a straight-pull steel wire 1 with an end 11, and the two sides of the hub 2 respectively form a plurality of connecting protrusions evenly distributed in the shape of a ring 21. Each of the connecting protrusions is provided with a fixing hole radially along the hub shaft hole. Each of the straight-pull steel wires 1 passes through a limiting block, and moves through the fixing hole on the corresponding connecting protrusion, and then is fixed to the wheel wheel. Ring 3, each of the limiting blocks forms an arc-shaped convex surface that facilitates the free rotation of the straight-pull steel wire.

[0022] In order to facilitate the free rotation of the straight-pull steel wire, each of the limiting blocks is a spherical washer 4, and the spherical wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com