Garbage can capable of compressing garbage

A technology for dustbins and garbage, which is applied in the field of bevel gear transmissions and dustbins. It can solve the problems of inconvenient application and lack of dustbins, and achieve the effect of enhancing the awareness of participating in environmental protection and expanding the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

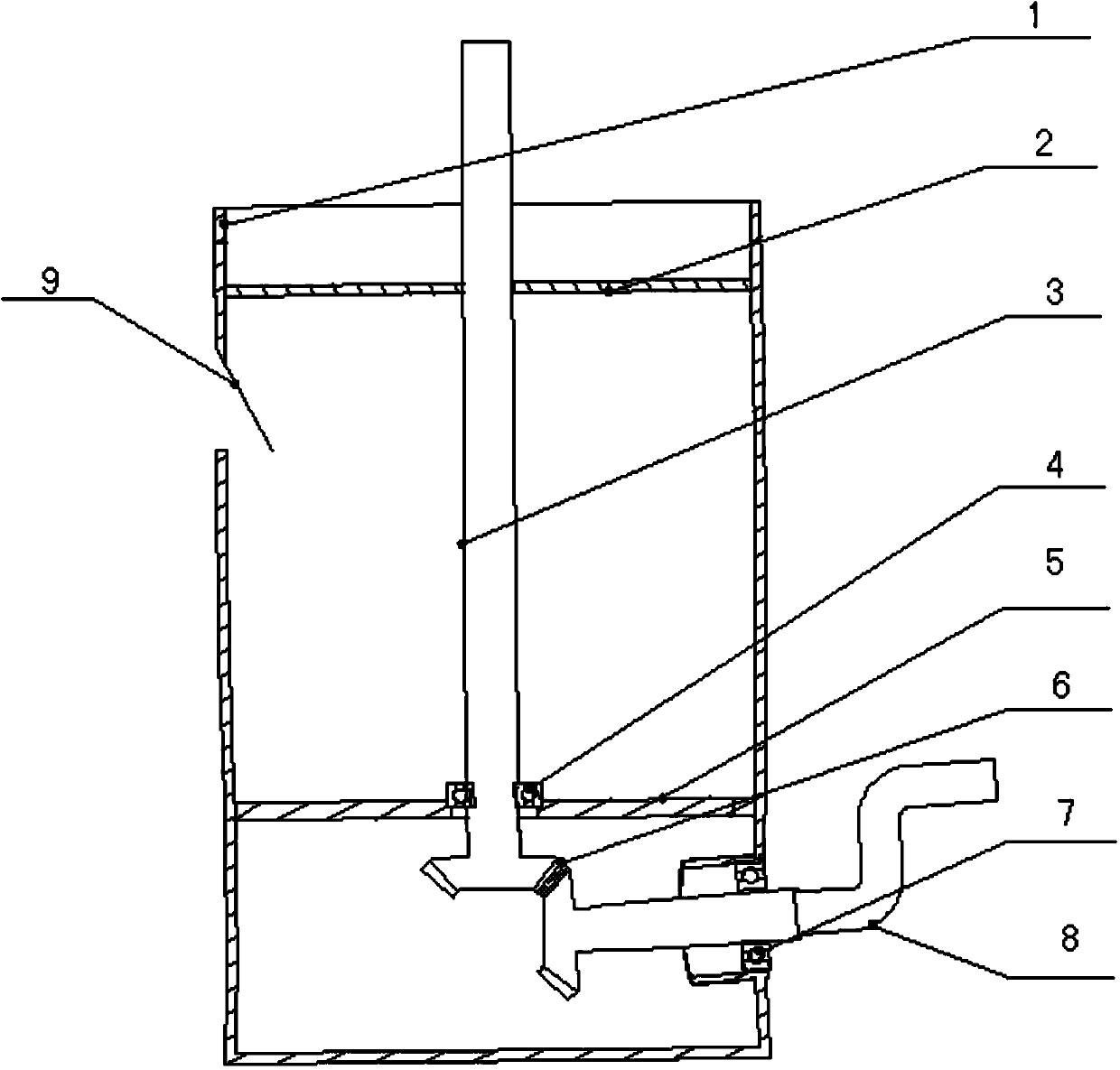

[0008] As shown in the figure, a dustbin that can compress garbage is composed of a first-level dustbin body 1, a dustbin cover 2, a vertical screw 3, an upper bearing 4, a bottom plate 5, a meshing bevel gear 6, and a lower bearing 7. , a rocker 8, and a box mouth baffle 9. It is characterized in that: the first-level dustbin body 1 and the second-level dustbin body are connected by threads to facilitate changing the volume of the dustbin, and the first-level dustbin body 1 side The lower bearing 7 installed on the wall fixes the rocking bar 8, and the upper bearing 4 installed on the base plate 5 fixes the vertical screw 3, and the rocking bar 8 and the vertical screw 3 are meshed by conical gears.

[0009] When the device is working, the garbage can be put in normally by pushing the baffle plate 9 at the mouth of the box. When the garbage is full, the rocker 8 is rotated, and the vertical screw 3 is rotated by engaging the bevel gear 6, driving the garbage bin cover 2 along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com