A method of replacement and support for strongly expansive muddy soft rock roadway

A technology of strong expansion and roadway, which is used in the support of mining engineering and the field of replacement and support of strong expansion muddy soft rock roadway, can solve the problems of difficulty in forming an anchoring structure, low rigidity, and difficulty in implementing grouting reinforcement, and achieve isolation. The effect of surrounding rock expansion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

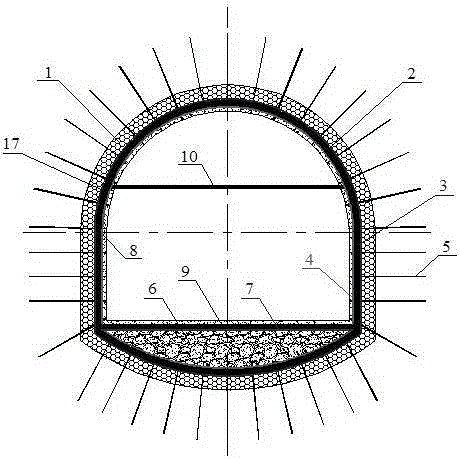

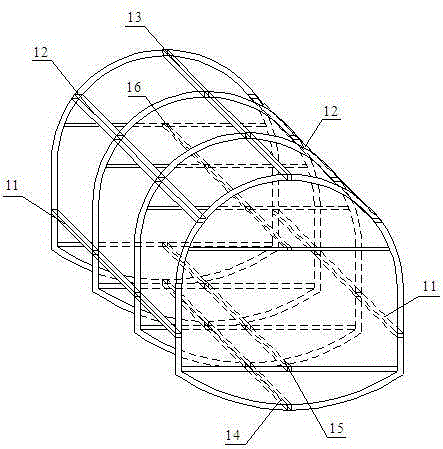

[0023] Such as figure 1 As shown, the strong expansive muddy soft rock roadway replacement and support method of the present invention includes three parts: quicklime replacement filling, high-strength shed support, anchor mesh spray extrusion arch support, wherein the quicklime replacement filling is the use of quicklime The cushion layer 1 replaces part of the strongly expansive muddy soft rock, and the high-strength shed support uses high-strength support 3 to strengthen the support. Reinforcement work. The specific implementation process of this support method is described in detail as follows.

[0024] During the excavation process of strong expansive muddy soft rock roadway, appropriate overbreak is carried out, and the overbreak amount is controlled at 400~600mm. After the roadway excavation is completed, a series of support work will be carried out. The specific steps are as follows:

[0025] (1) Erect the outer frame of the high-strength support 3, the radial dimens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com