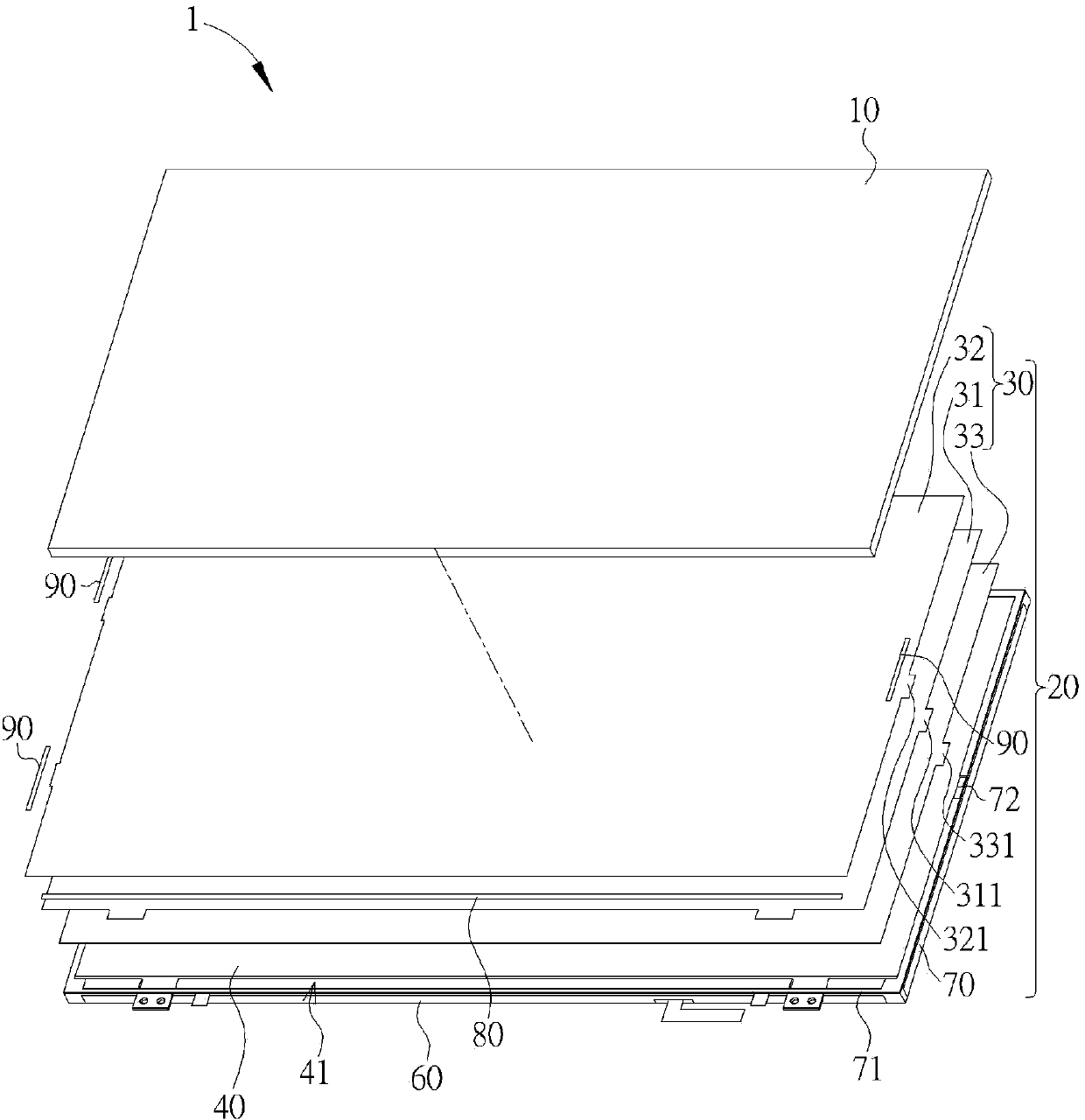

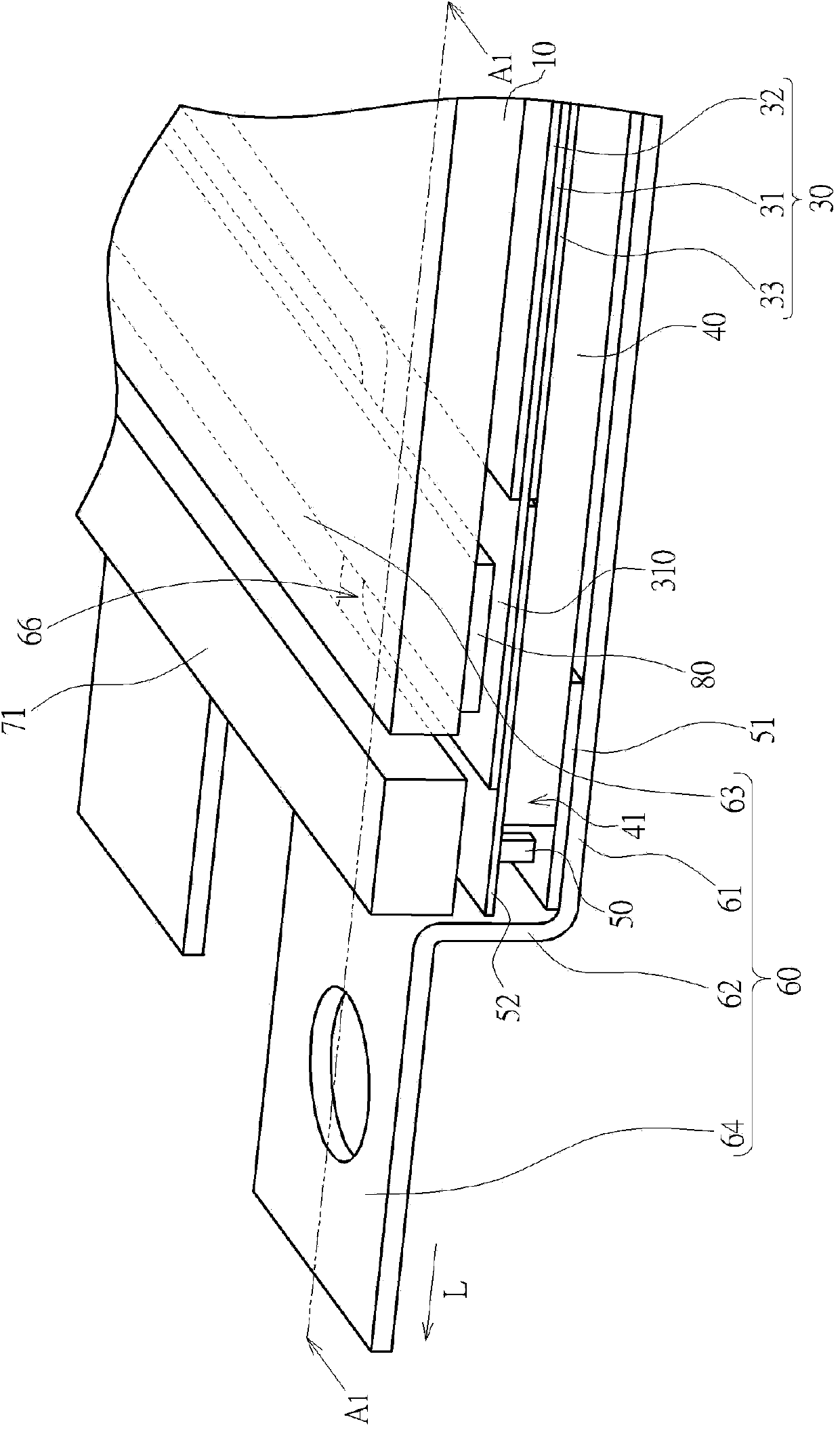

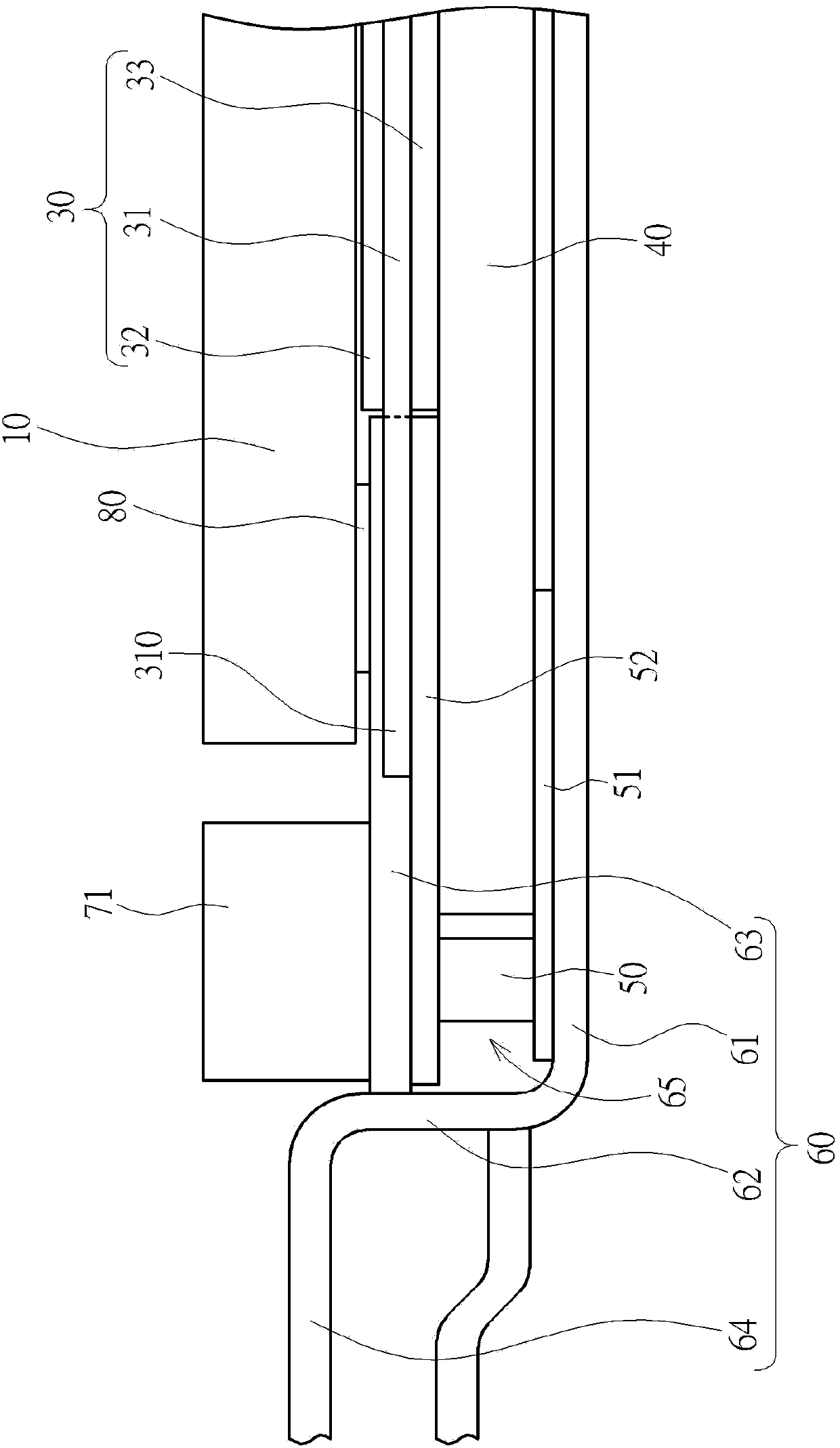

Display Module

A technology for displays and display panels, applied in the directions of instruments, light guides, optics, etc., can solve the problems of tape loosening, jumping off, and displacement of optical films of optical films, and achieve the effect of proper fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Certain terms are used throughout the specification and following claims to refer to particular elements. Those of ordinary skill in the art will appreciate that manufacturers may refer to the same element by different terms. The scope of this specification and the following claims does not use the difference in name as the way to distinguish components, but the difference in function of the components as the criterion for distinguishing. The "comprising" mentioned throughout the specification and subsequent claims is an open term, so it should be interpreted as "including but not limited to". Furthermore, the terms "coupled" or "connected" herein include any direct or indirect electrical or structural means of connection. Therefore, if it is described in the text that a first device is coupled / connected to a second device, it means that the first device may be directly electrically / structurally connected to the second device, or indirectly electrically / structurally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com