I-shaped steel welding device

A welding device and I-beam technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems that H-beams are prone to shaking or shifting, affecting the success rate of H-beam welding, and hidden safety hazards of H-beam scrapping , to achieve the effect of saving manpower, improving welding efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

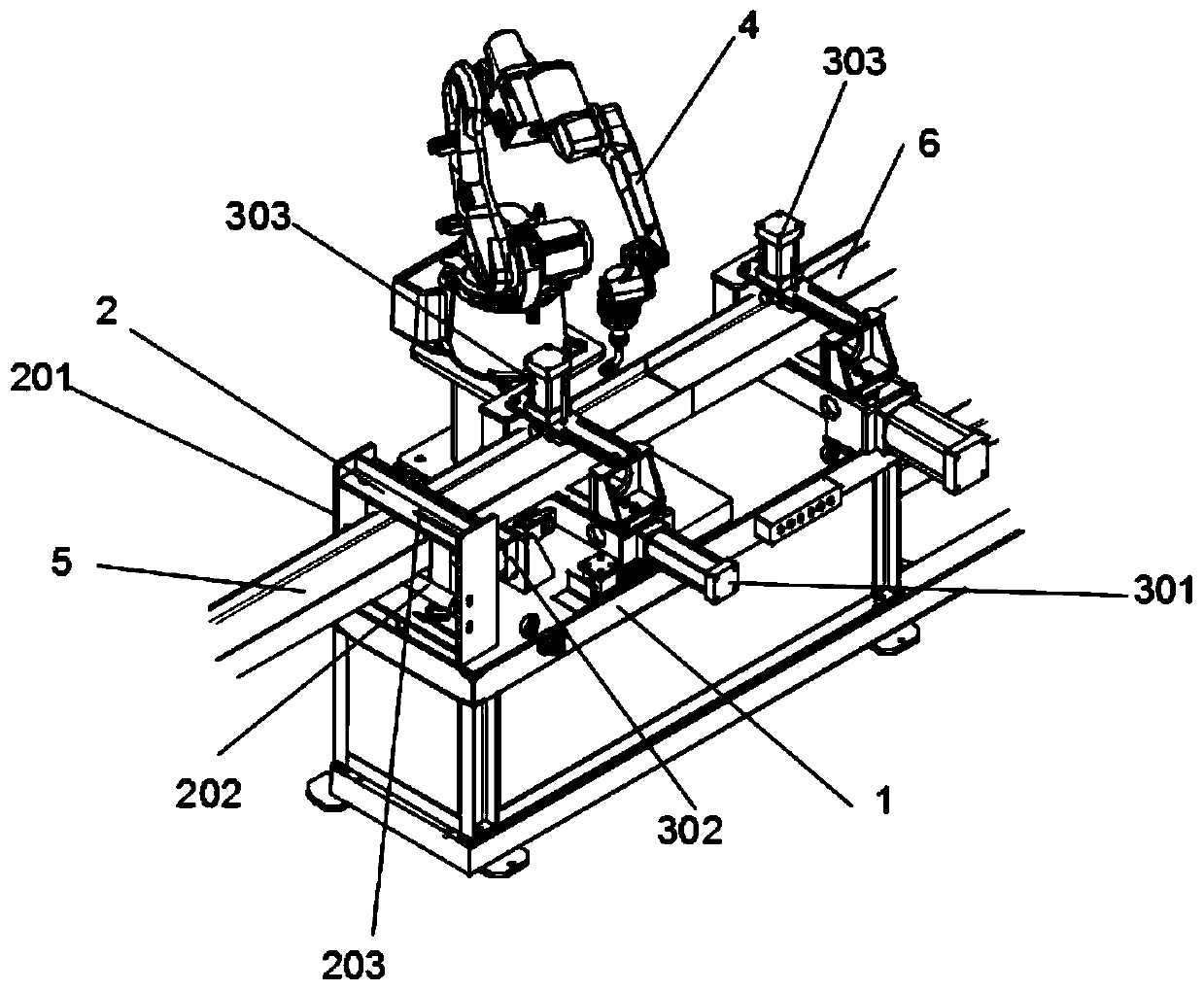

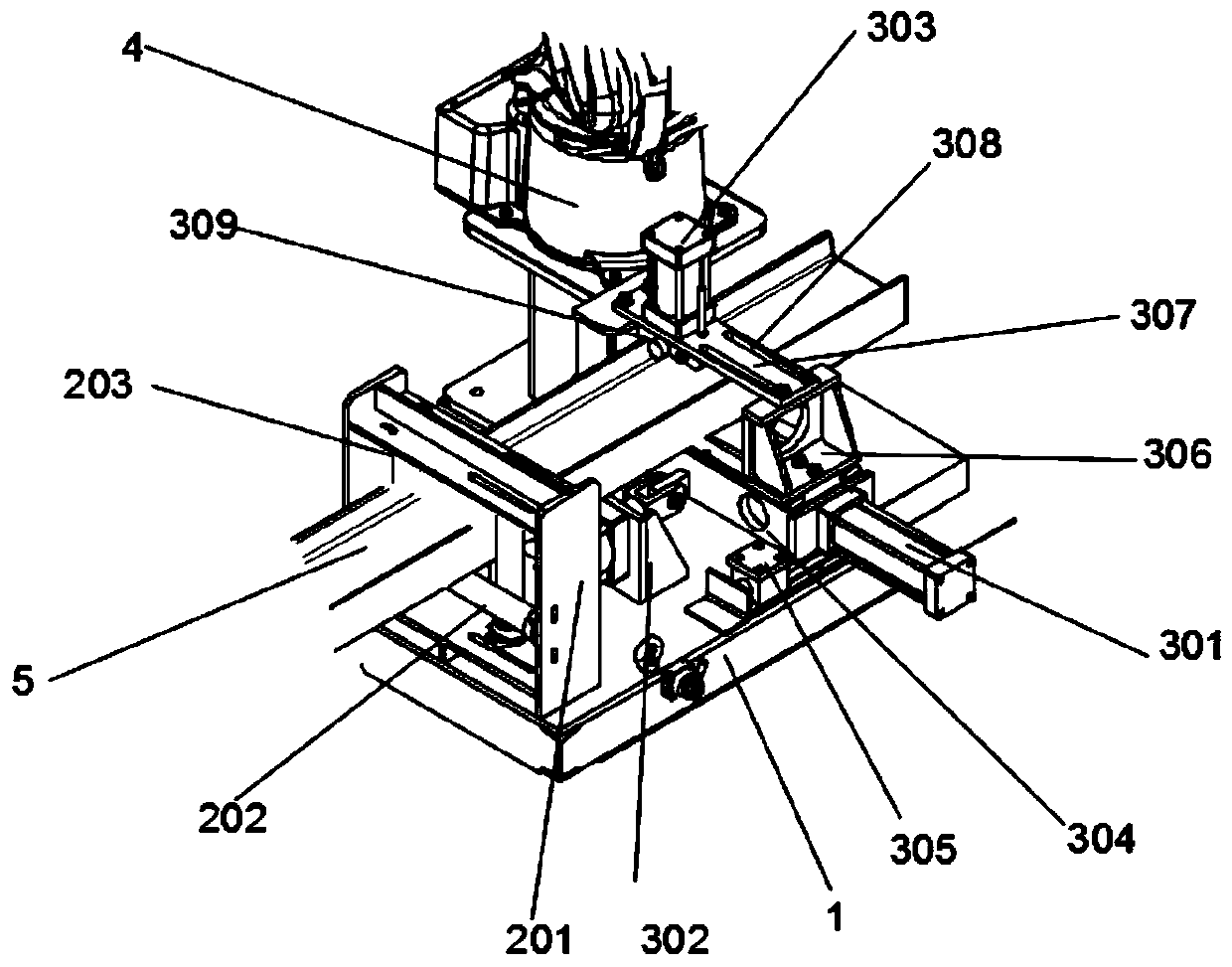

[0027] Specific embodiment 1. An I-beam welding device includes a welding device body. The welding device body includes a rectangular frame 1. The bottom of the frame 1 is fixed with a base and the top is an operating platform. The top of the frame 1 is fixedly connected with a limit mechanism 2 , a positioning mechanism 3 and a welding mechanism 4 .

[0028] Wherein the position limiting machine 2 includes a first fixed frame 201 arranged vertically, and two fixed frames 201 are arranged symmetrically on both sides of the frame 1 . The bottom of the first fixed frame 201 is fixed with a roller 202 , and the top of the first fixed frame 201 is fixed with a limit rod 203 ; the limit rod 203 is arranged parallel to the top of the frame 1 . The rollers 202 are located away from the bottom of the frame 1 .

[0029] The positioning mechanism 3 includes a first cylinder 301 , a second cylinder 302 and a third cylinder 303 . The first cylinder 301 is arranged along the width direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com