Semi-pneumatic hanging table sweeping-head machining clamp assembly

A clamping and cylinder technology, applied in the field of semi-pneumatic hanging table sweeping head processing clamping group, can solve the problems of time-consuming, labor-intensive, inability to clamp flat, affecting accuracy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

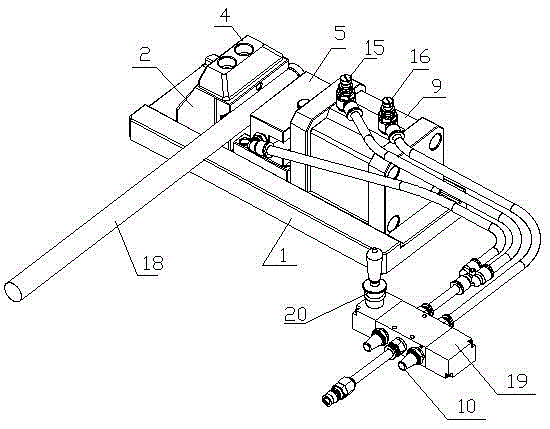

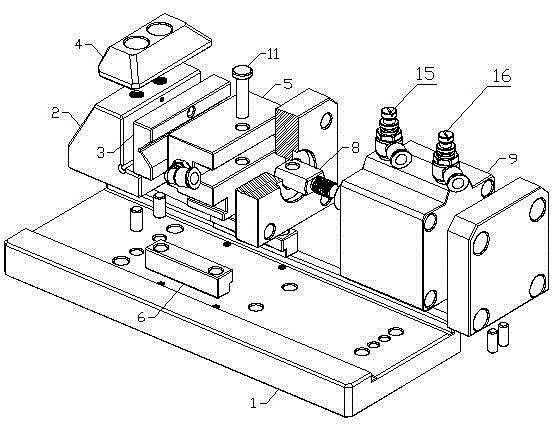

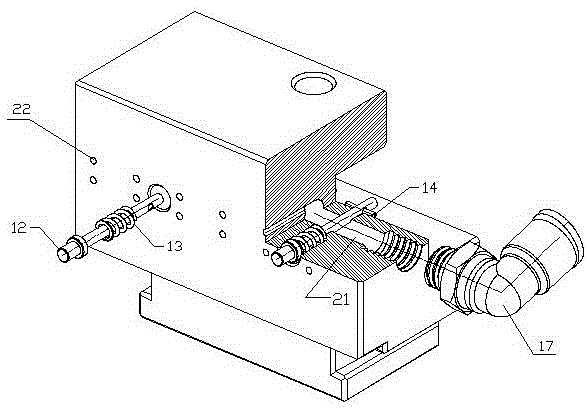

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-Figure 3 As shown, a semi-pneumatic hanging table sweeping head processing clamping group includes a base plate 1, one end of the base plate 1 is provided with a fixed block 3, and the other end is provided with a clamping slider that can move horizontally relative to the fixed block 3 5, and the side surface of the fixed block 3 opposite to the clamping slider 5 is provided with a V-shaped groove; the clamping slider 5 is driven by a cylinder 9, and the cylinder 9 is manually replaced by two air pipes. The reversing valve 19 is connected with the air source, and the manual reversing valve 19 is provided with a reversing valve handle 20 .

[0024] When it is necessary to fix the product 18, use the reversing valve handle 20 to control the cylinder 9 to move toward the fixed block 3, so that the clamping slider 5 slowly moves toward the V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com