Shock absorption and fixing equipment used in porcelain transporting process

A technology for transporting and fixing equipment, applied in the field of shock-absorbing fixed equipment, can solve the problems of too many filling materials, the device cannot be used in a cycle, affecting protection, etc., and achieves the effect of simple fixing and good shock-absorbing protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

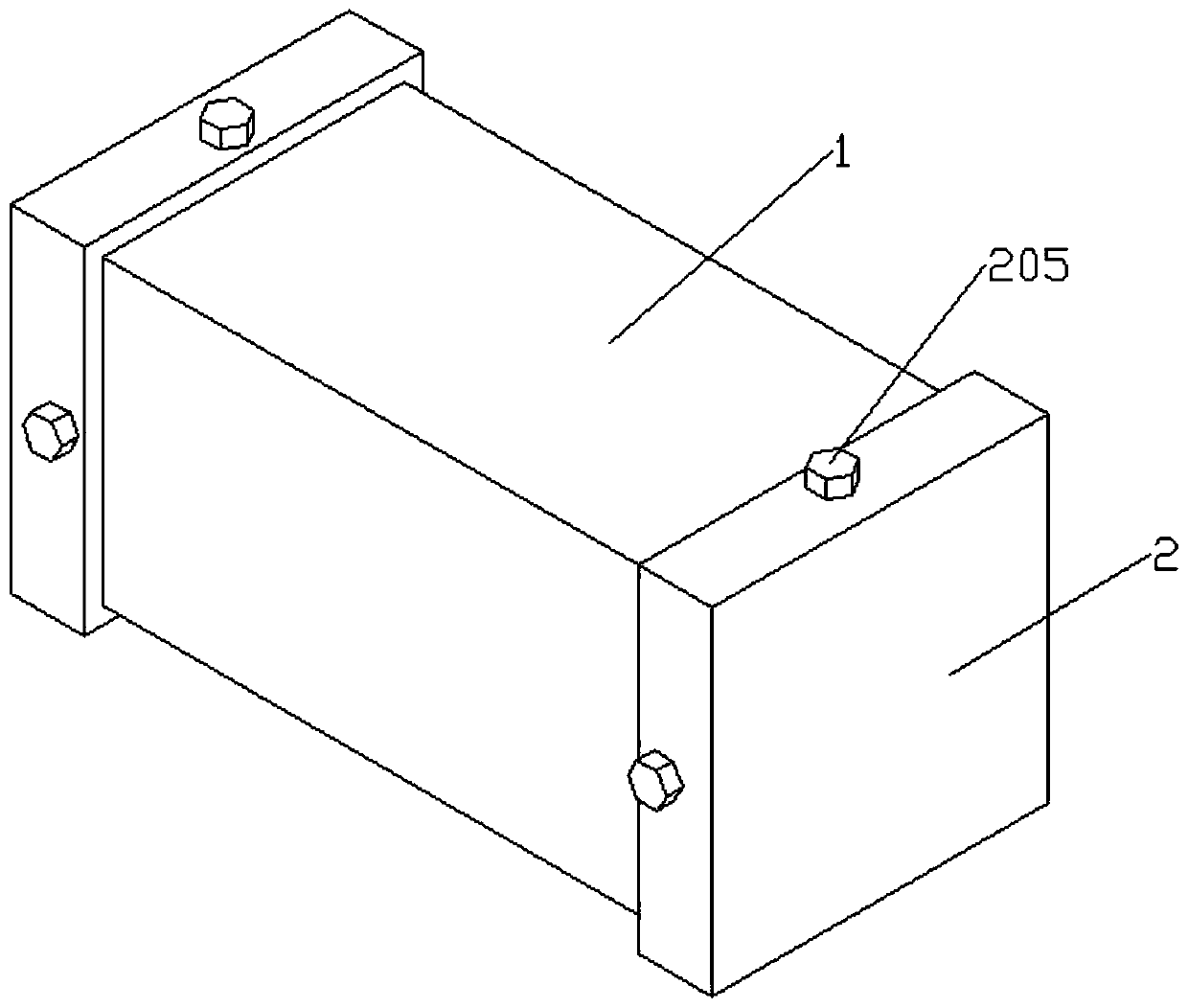

[0027] A shock-absorbing and fixing device during the transportation of porcelain, comprising a transport box 1, a cover body 2 and a shock-absorbing and fixing mechanism 3;

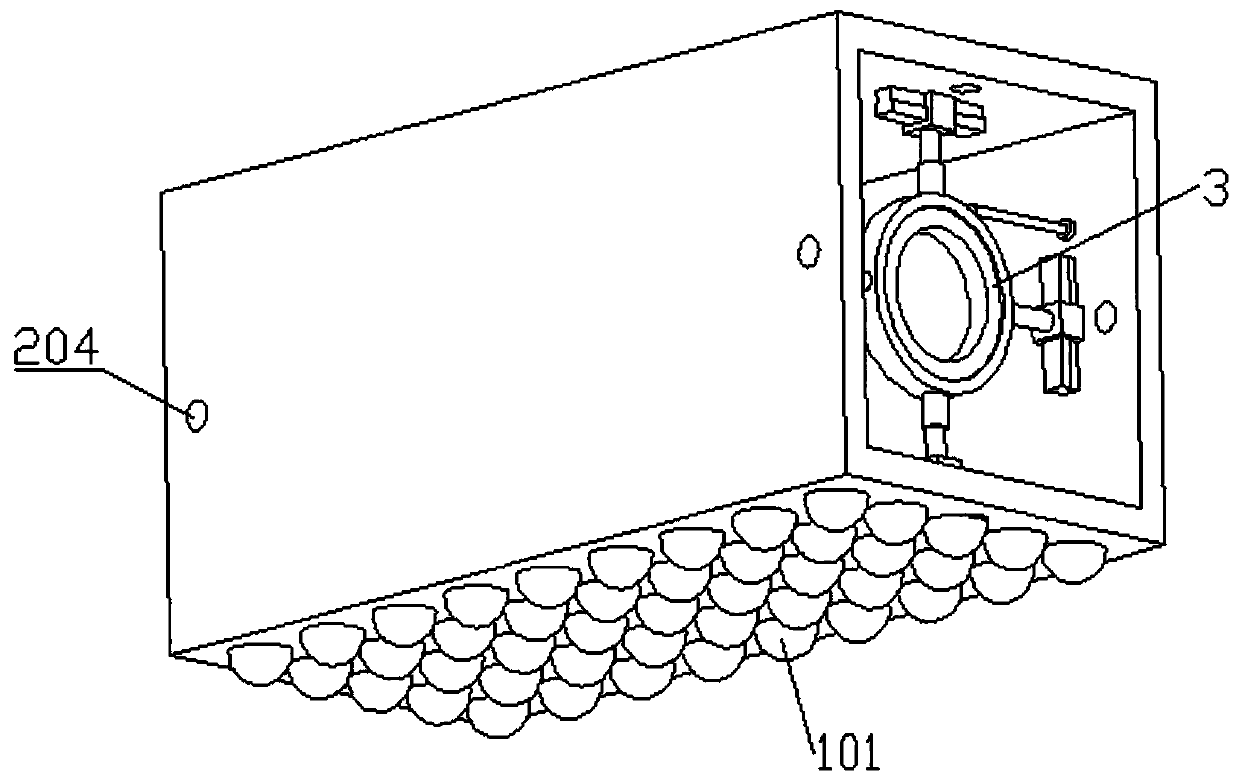

[0028] The transport box 1 is arranged horizontally, the transport box 1 is a cuboid cavity structure with open left and right ends, the lower surface of the bottom plate of the transport box 1 is densely covered with hemispherical anti-slip protrusions 101, and the anti-slip protrusions 101 are made of hard rubber;

[0029] The cover body 2 fits on the left and right ends of the transport box 1 and closes the left and right sides of the transport box 1;

[0030] The shock absorbing and fixing mechanism 3 is evenly arranged horizontally in the transport box 1, and the number of the shock absorbing and fixing mechanism 3 is not less than three places. The shock absorbing and fixing mechanism 3 includes a track plate 301 and a fixed air bag 302. The cross section of the track bar is T-shaped, and the track ...

Embodiment 2

[0032] The difference from Example 1 is that it also includes the following:

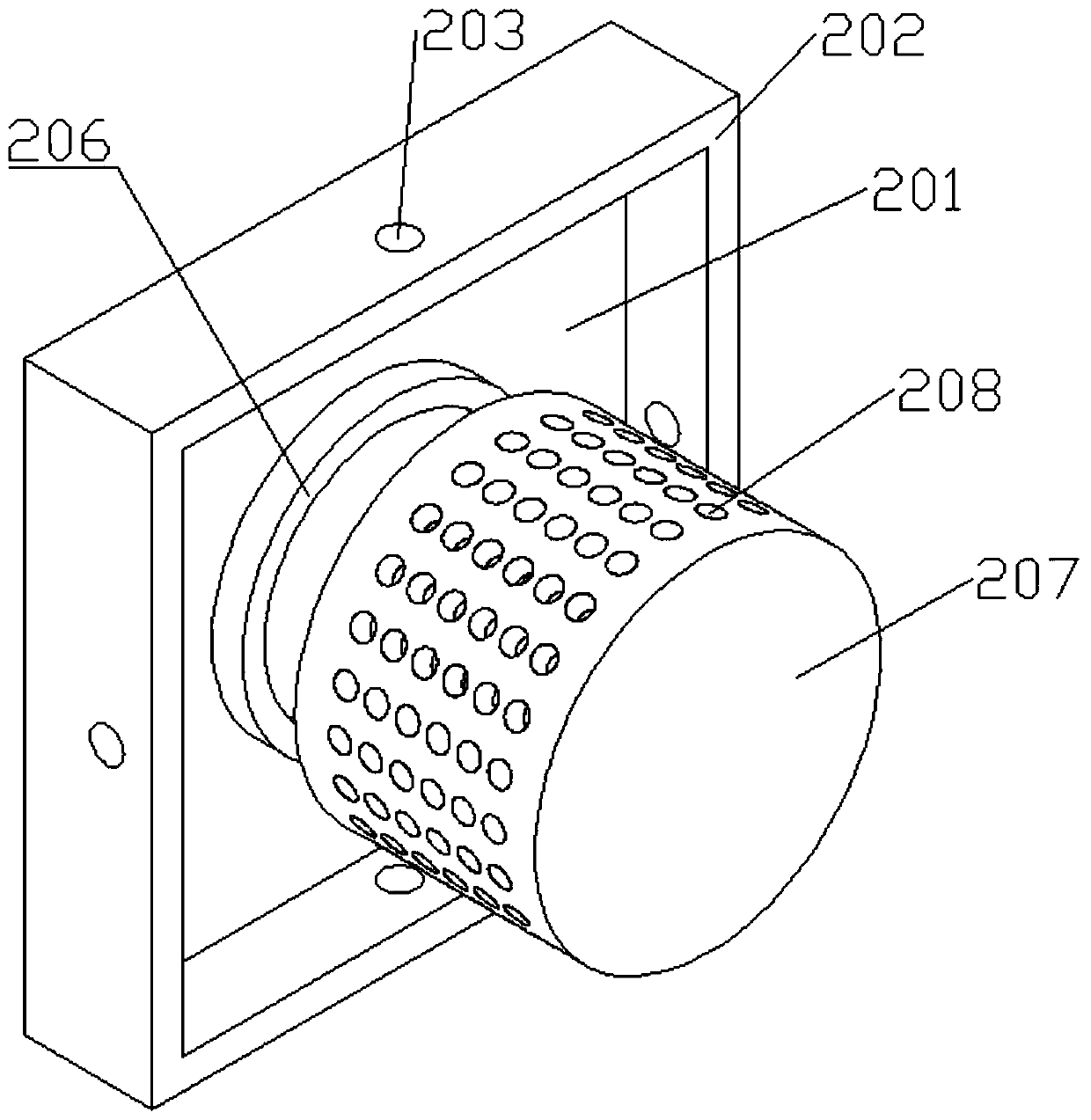

[0033] Cover body 2 comprises cover plate 201 and enclosure plate 202, and enclosure plate 202 is provided with four, and four enclosure panels 202 are arranged in a rectangle, and the space formed by enclosure plate 202 fits with transport case 1, and each enclosure plate 202 is provided with the first One fixed screw hole 203, each side plate of transport box 1 is provided with the second fixed screw hole 204 corresponding to the first fixed screw hole 203 one by one, the paired first fixed screw hole 203 and the second fixed screw hole 204 The connection is through the fixing screw 205.

Embodiment 3

[0035] The difference from Example 2 is that it also includes the following:

[0036] The inner wall of the cover plate 201 is fixedly connected with a connecting sleeve 206, and also includes a drying cylinder 207. The drying cylinder 207 is screwed to the connecting sleeve 206. The arc-shaped plate of the drying cylinder 207 is densely covered with through holes 208. The drying cylinder 207 is filled with desiccant. , The desiccant is made of colored silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com