Touch control color film base plate, manufacturing method of touch control color film base plate, display panel and display device

A color filter substrate and manufacturing method technology, applied in optics, instruments, electrical digital data processing and other directions, can solve the problems of affecting LCD transmittance, increasing process complexity, and manufacturing processes are not on the same side, so as to reduce process complexity. , The effect of eliminating the inversion process and improving the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

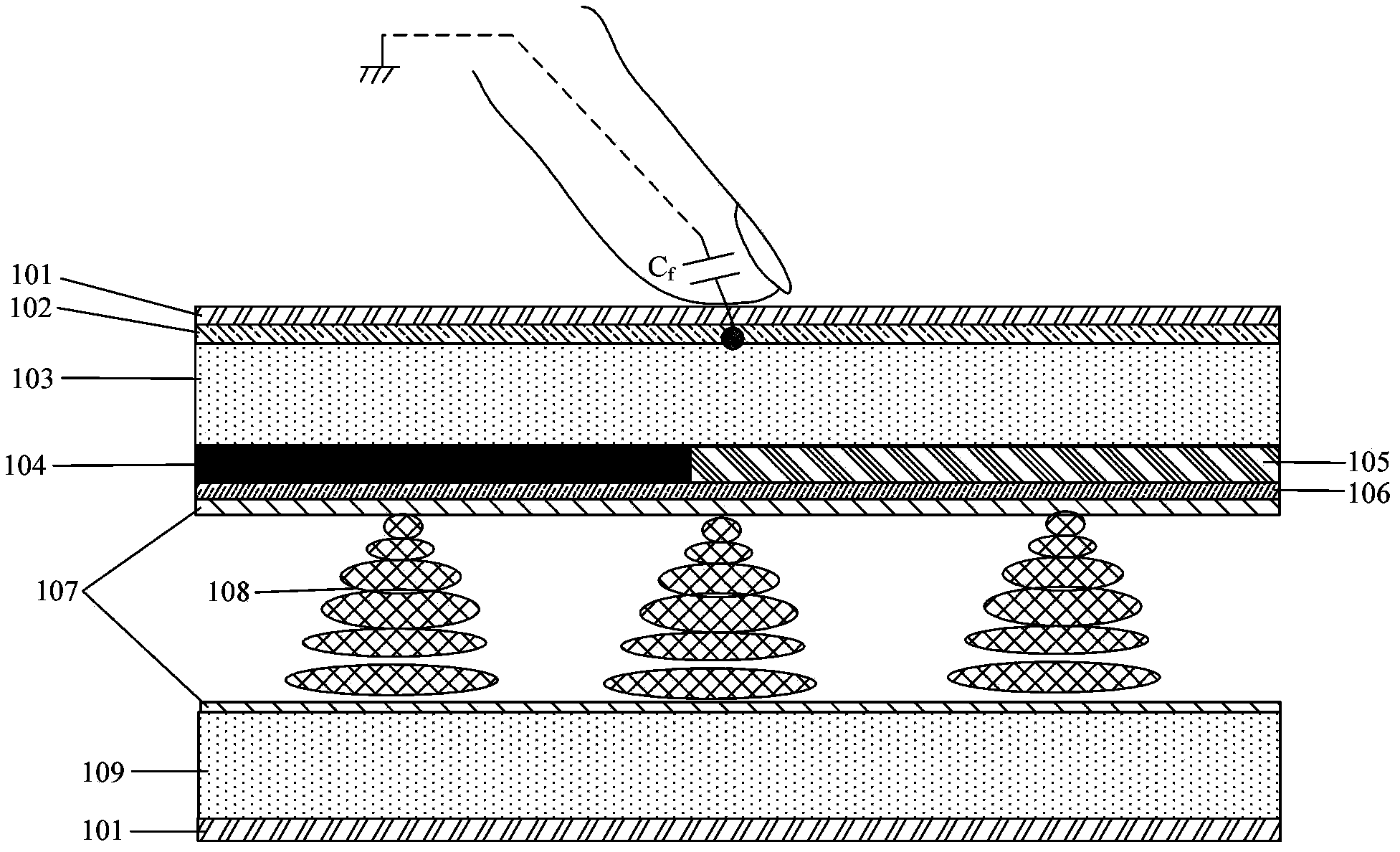

[0032] The technical solutions of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

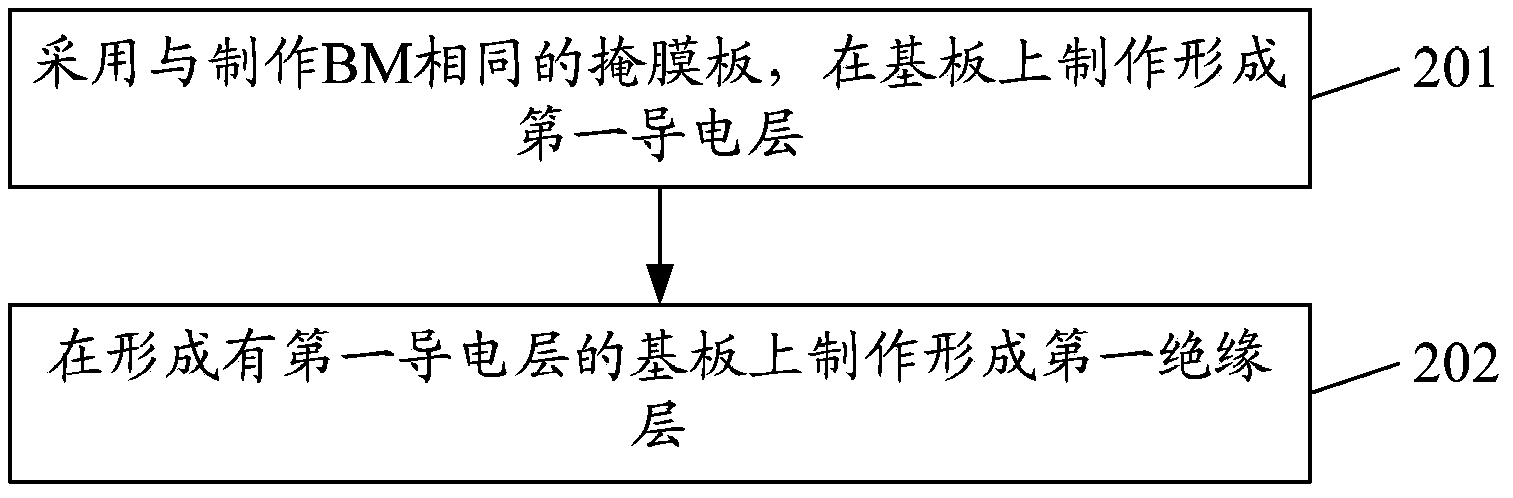

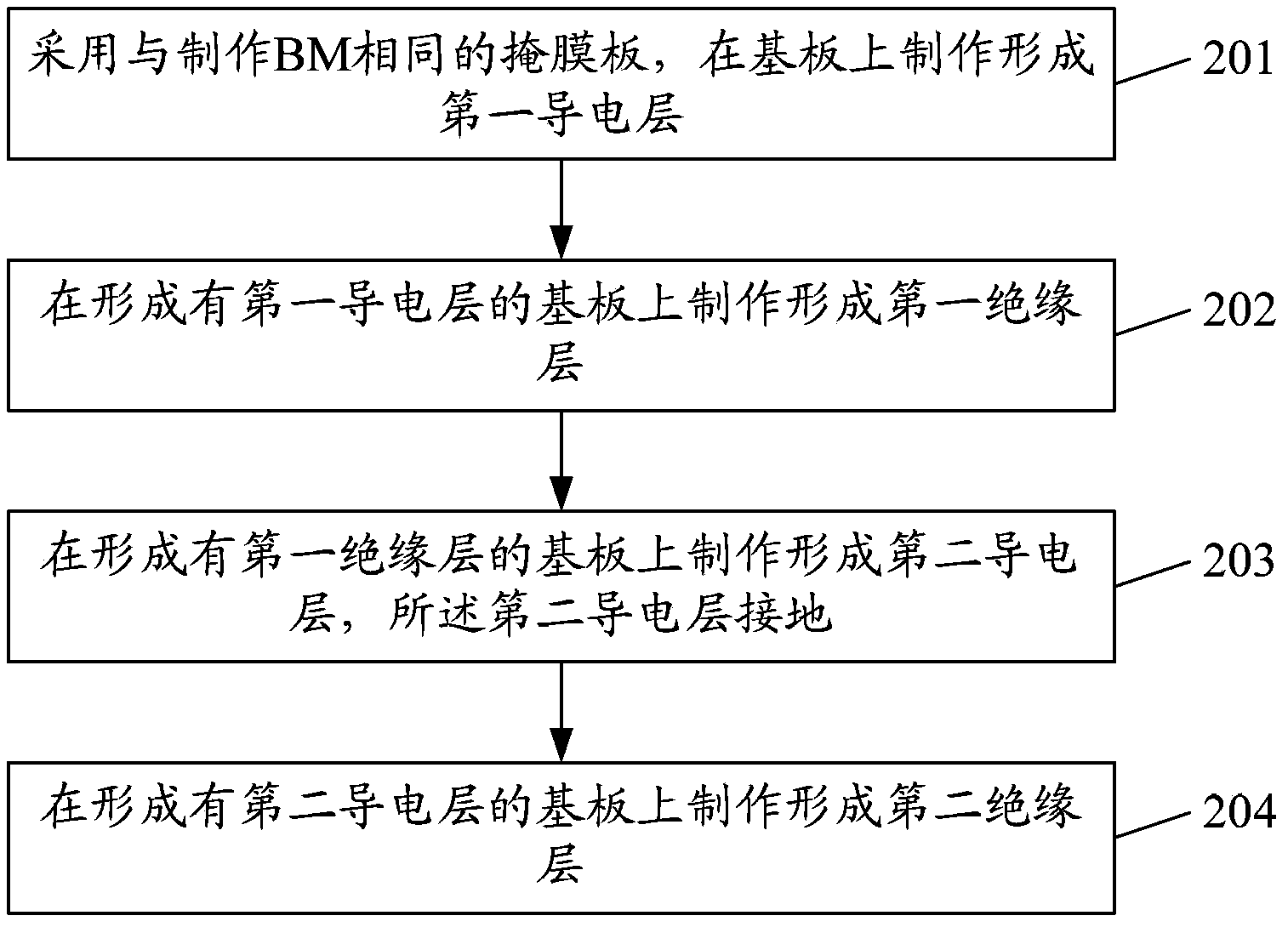

[0033] An embodiment of the present invention provides a method for manufacturing a touch color filter substrate, such as figure 2 As shown, the method mainly includes:

[0034] In step 201, a first conductive layer is formed on a substrate by using the same mask as that used for forming a black matrix (BM).

[0035] The substrate used to make the color filter (CF) substrate may be a glass substrate or a plastic substrate. On the substrate used to fabricate the color filter (CF), the first conductive layer is fabricated and formed using the same mask as that used to fabricate the BM. That is to say, the same mask is used to manufacture the first conductive layer and the BM, so the patterns of the first conductive layer and the BM formed on the touch color filter substrate are the same. The first conductive layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com