Processing method of horn basin stand

A technology of a horn basin frame and a processing method, which is applied to the processing field of the basin frame, can solve the problems of inconsistent processing steps, poor quality, and no standard requirements for dimensions, and achieves the effects of good control, good workpiece quality, and high dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

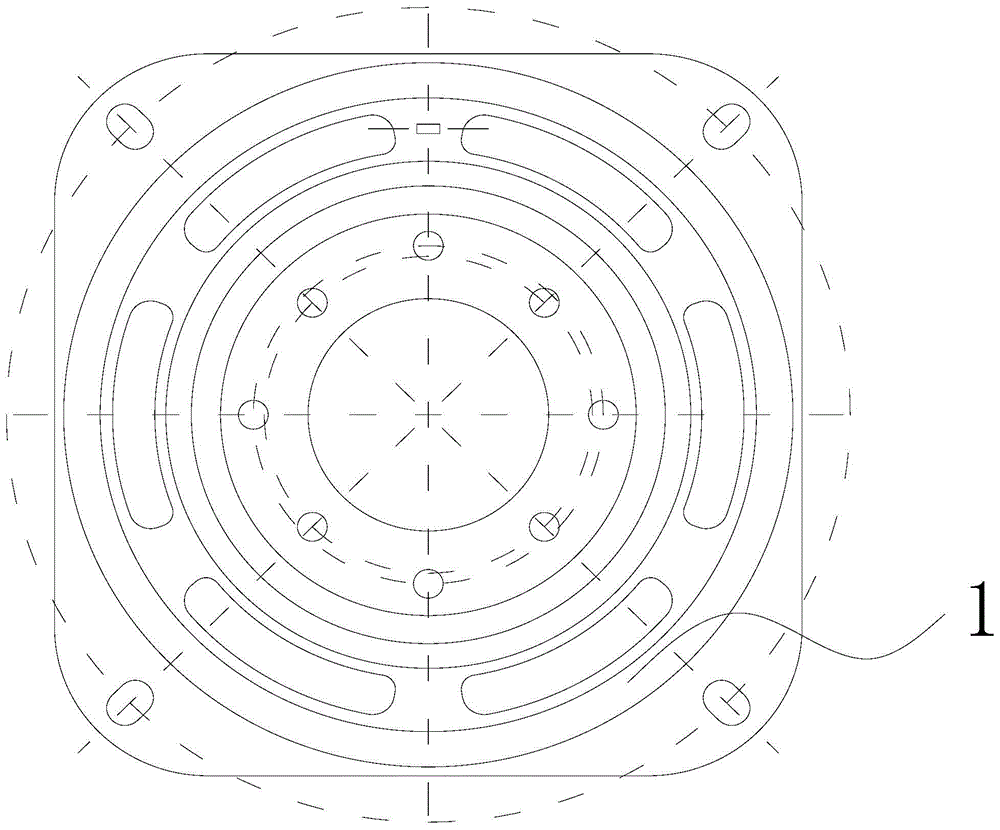

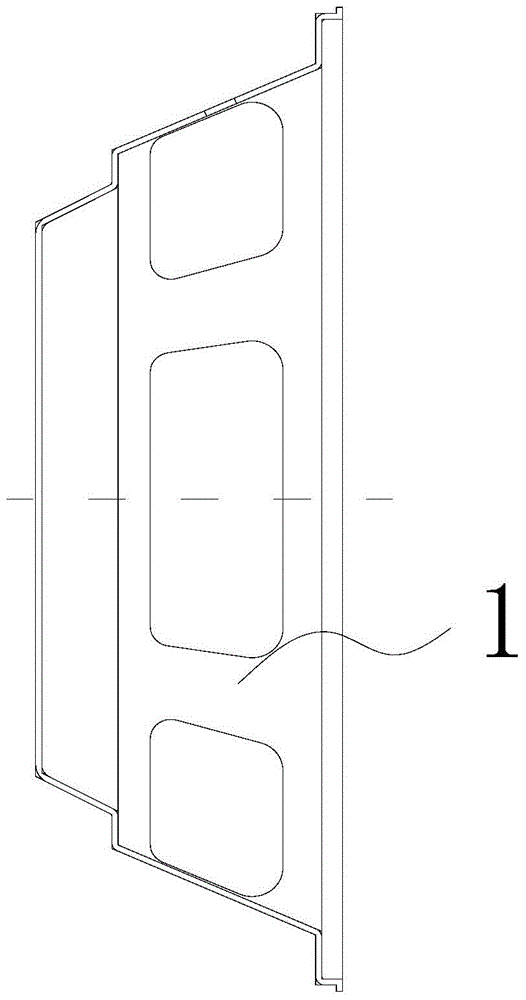

[0026] refer to figure 1 and 2 As shown, this is the workpiece pattern processed by the processing method of the present invention, including the horn basin body 1 .

[0027] A kind of processing method of 1025 type horn basin frame of the present invention, comprises the following steps:

[0028] (1) Cutting: cutting according to the specifications and dimensions of the trumpet pot frame. The above steps use a shearing machine, and the operating standards refer to the "Shearing Machine Operation / Inspection Guide".

[0029] (2) Cutting and drawing: drawing and forming according to the specifications and dimensions of the trumpet basin frame. The above steps use a 40T punch, and share the matching drawing die of this model. The operating standards refer to the "Stampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com