Preparation method of color-superposed color coating of amorphous structure

An amorphous structure, color coating technology, applied in the direction of coating, device for coating liquid on the surface, silicon dioxide, etc., can solve the problems of cumbersome process, limitation, low controllability, etc., and achieve broad application prospects , mild conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

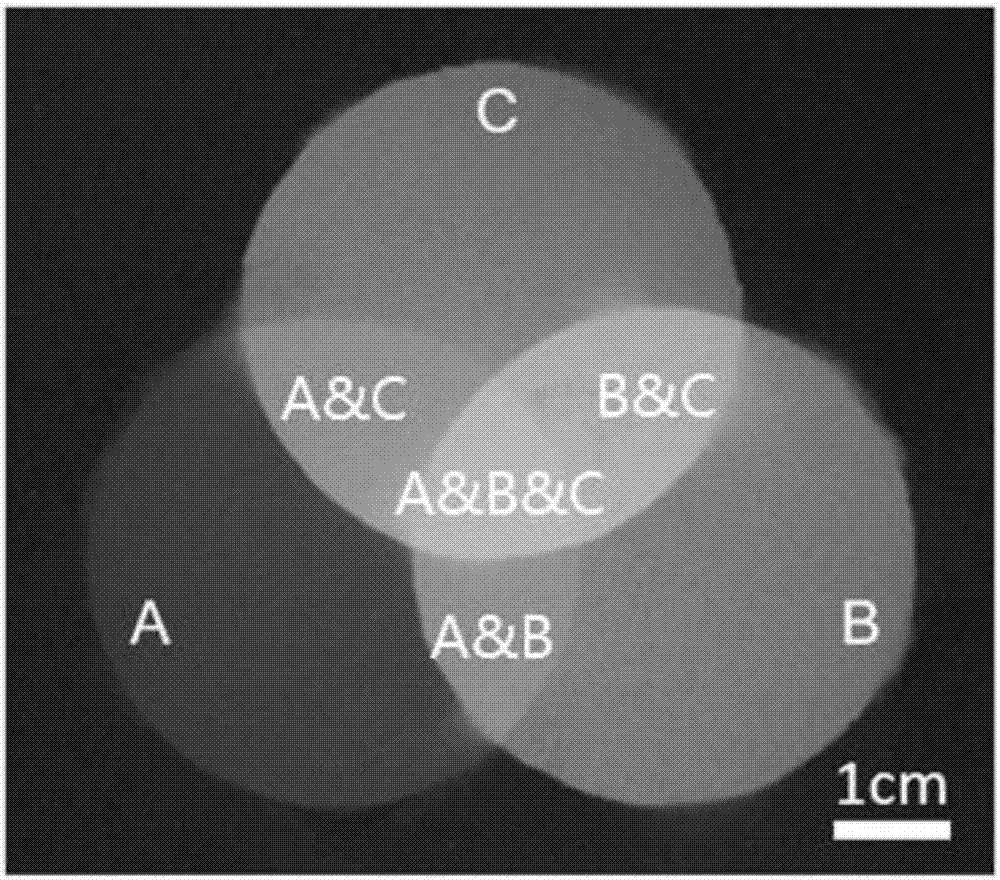

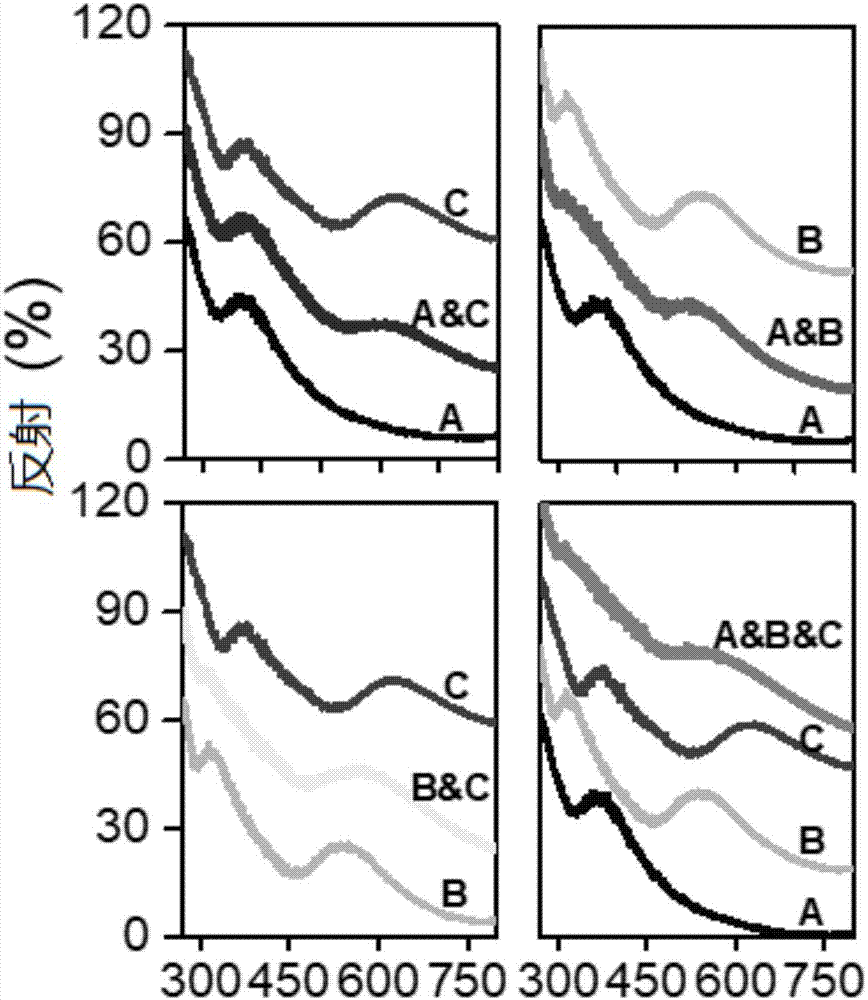

Embodiment 1

[0029] (1) SiO with a diameter of 167nm 2 Disperse in water to prepare an aqueous dispersion with a mass fraction of 1%. Take 2ml of the above aqueous dispersion, put it into an ordinary ultrasonic atomizer, use ordinary black kraft paper as the base, place the kraft paper in the atomized gas for 20 minutes, and deposit the thickness of 4μm, and then dry it completely to form a circular first layer Amorphous structural color coating with an angle-independent blue color. Among them, the atomization condition is normal temperature, and the rate is ≥0.3ml / min.

[0030] (2) SiO with a diameter of 236nm 2 Disperse in water to prepare aqueous dispersions with a mass fraction of 1%. Take 2ml of the above-mentioned aqueous dispersion, put it into an ordinary ultrasonic atomizer, and deposit the atomized aqueous dispersion on the first layer of amorphous structural color coating according to the conditions of step (1). The deposition thickness is 4 μm, forming a circle Shaped secon...

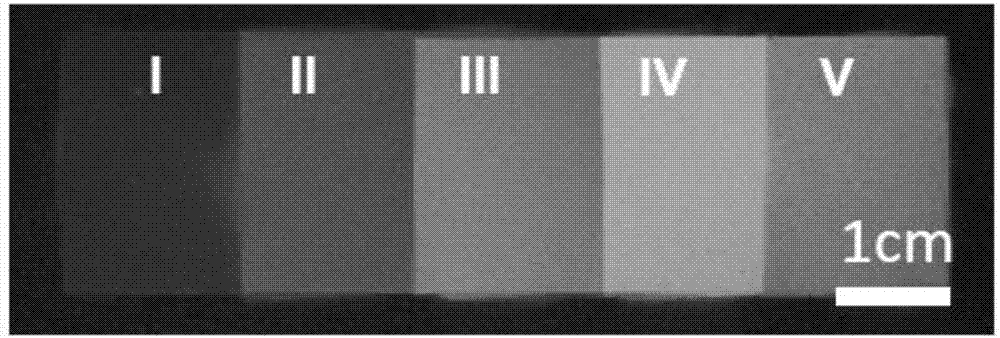

Embodiment 2

[0034] (1) SiO with a diameter of 167nm 2 Disperse in water to prepare an aqueous dispersion with a mass fraction of 1%. Take 2ml of the above aqueous dispersion, put it into an ordinary ultrasonic atomizer, use ordinary black kraft paper as the base, place the kraft paper in the atomized gas for 10 minutes, the deposition thickness is 2μm, and then dry it completely to form a rectangular first layer of non- A crystalline structural color coating that exhibits an angle-independent cyan color. Among them, the atomization condition is normal temperature, and the rate is ≥0.3ml / min.

[0035] (2) SiO with a diameter of 236nm 2Disperse in water to prepare aqueous dispersions with a mass fraction of 1%. Get 2ml of the above-mentioned aqueous dispersion, put it into a common ultrasonic atomizer, and deposit the atomized aqueous dispersion on the first layer of amorphous structural color coating according to the conditions of step (1), forming a rectangular second layer of amorphou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com