Color change head

A color-changing head and consistent technology, applied in the field of color-changing heads, can solve the problems of unreasonable design structure, inconsistent stroke, difficult adjustment, etc., and achieve the effect of simple structure, dexterous action and fast rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the following examples.

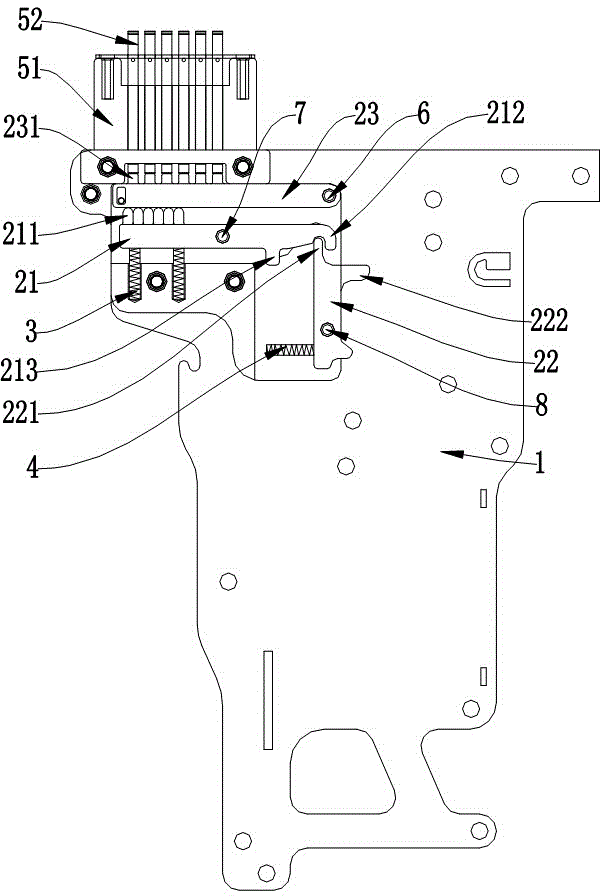

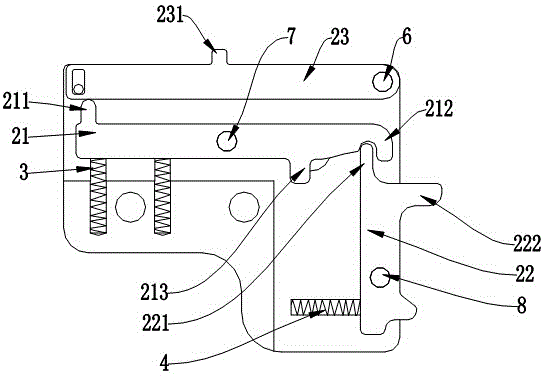

[0024] Such as Figure 1 to Figure 2 As shown, a color changing head includes a housing 1, and a control mechanism, a linkage mechanism and an action mechanism installed in the housing 1, the control mechanism includes a plurality of color selection boards, and the color selection boards are arranged at intervals , each of the color selection boards includes a first connecting rod 21 and a swing rod 23;

[0025] One end of the swing rod 23 is installed on the housing 1 using the first rotating shaft 6, so that the other end of the swing rod 23 can swing freely, and the upper edge of the swing rod 23 is provided with a first protrusion that can be pressed 231: The positions of the first protrusions 231 of different control mechanisms are inconsistent;

[0026] The middle part of the first connecting rod 21 is mounted on the housing 1 using the second rotating shaft 7 , and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap