Method for measuring noise of smelting fused magnesium in arc furnace

A technology of electric arc furnace and fused magnesium, which is applied in measuring devices, radio wave measuring systems, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of inability to track noise data, data cannot be used for noise source location, etc., to reduce work energy, suppressing noise, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail with reference to the accompanying drawings for a deeper understanding of the objects, features and advantages of the present invention.

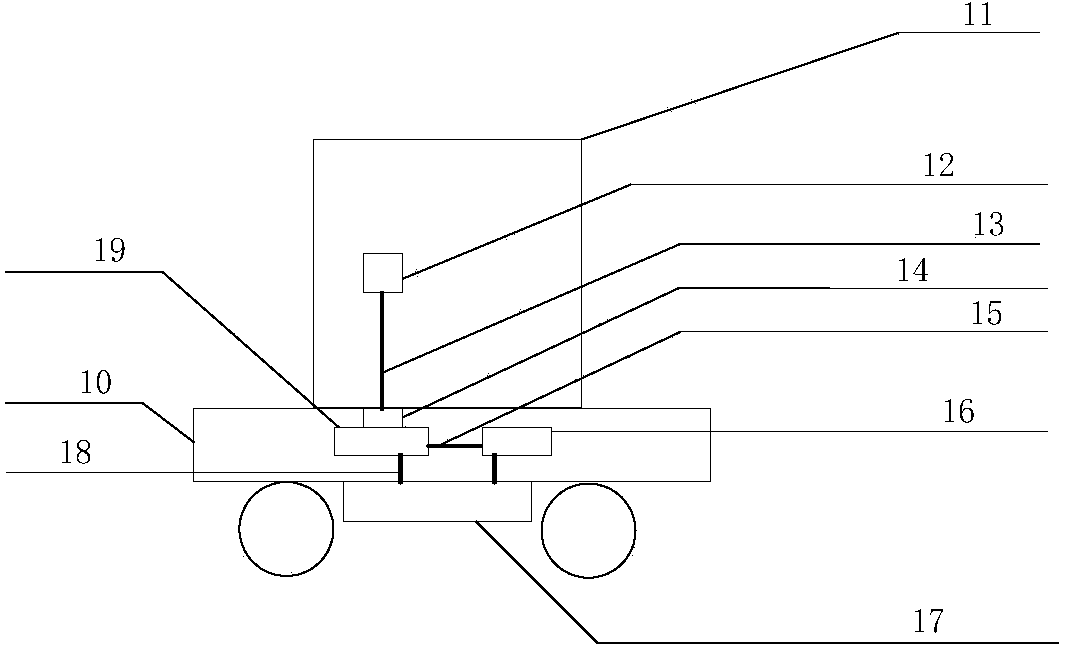

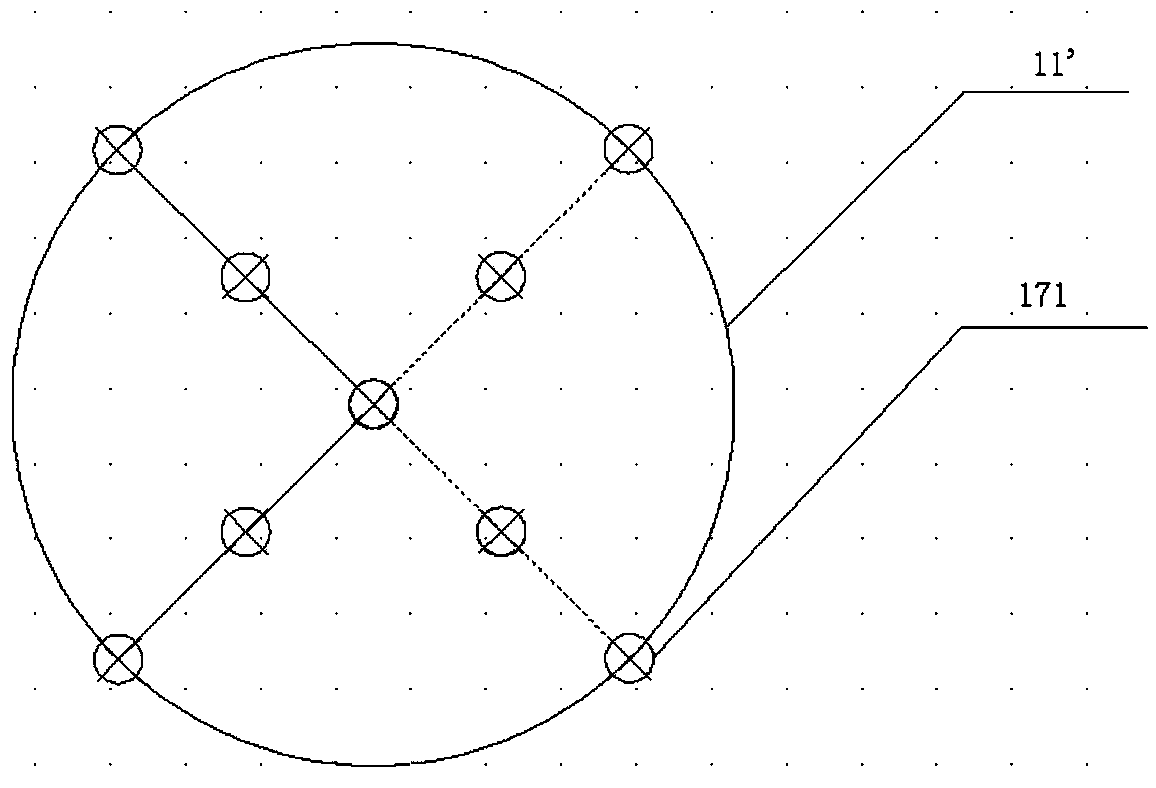

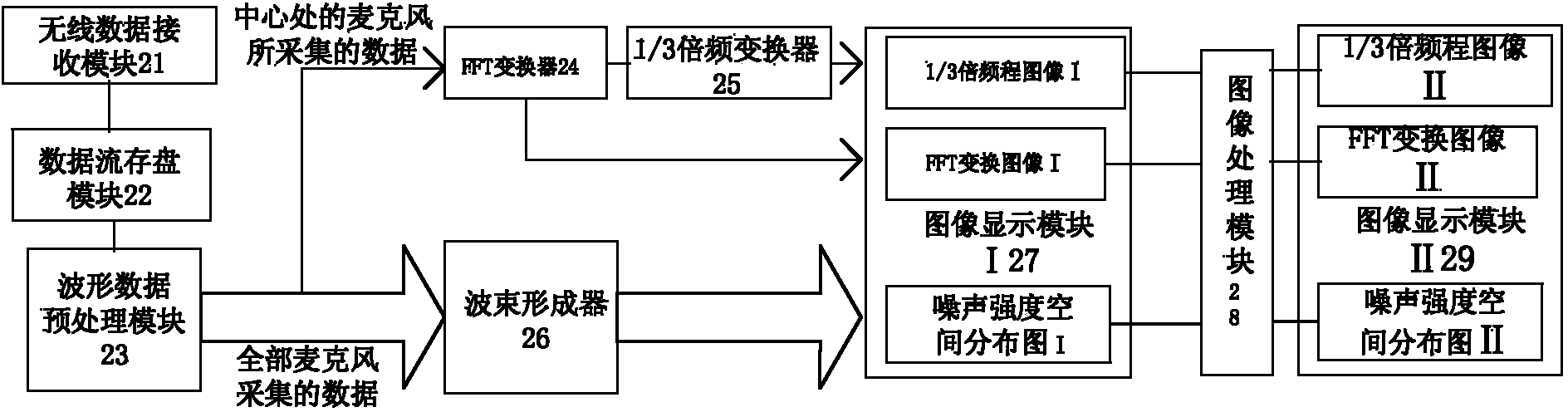

[0030] The detection equipment involved in the present invention mainly includes a noise collecting device and a noise signal receiving and processing device. Such as figure 1 As shown, the noise collection device mainly includes a thermoelectric power generation module 12 , a hot-swappable power interface 14 , a lithium battery power supply module 19 , a microphone array module 17 and a wireless router 16 . The arrangement height of the thermoelectric power generation module 12 is located in the middle of the furnace shell 11, because the surface temperature of the furnace shell there is the highest, which is conducive to improving the power generation efficiency. The thermoelectric power generation module 12 and the lithium battery power supply module 12 are connected through a pow...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap