Centrifugal cutterheads and mowers

A technology of lawn mowers and cutterheads, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of low cutting blade power and occupying a large space, so as to prevent fingers from getting close to the blade and reduce driving resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

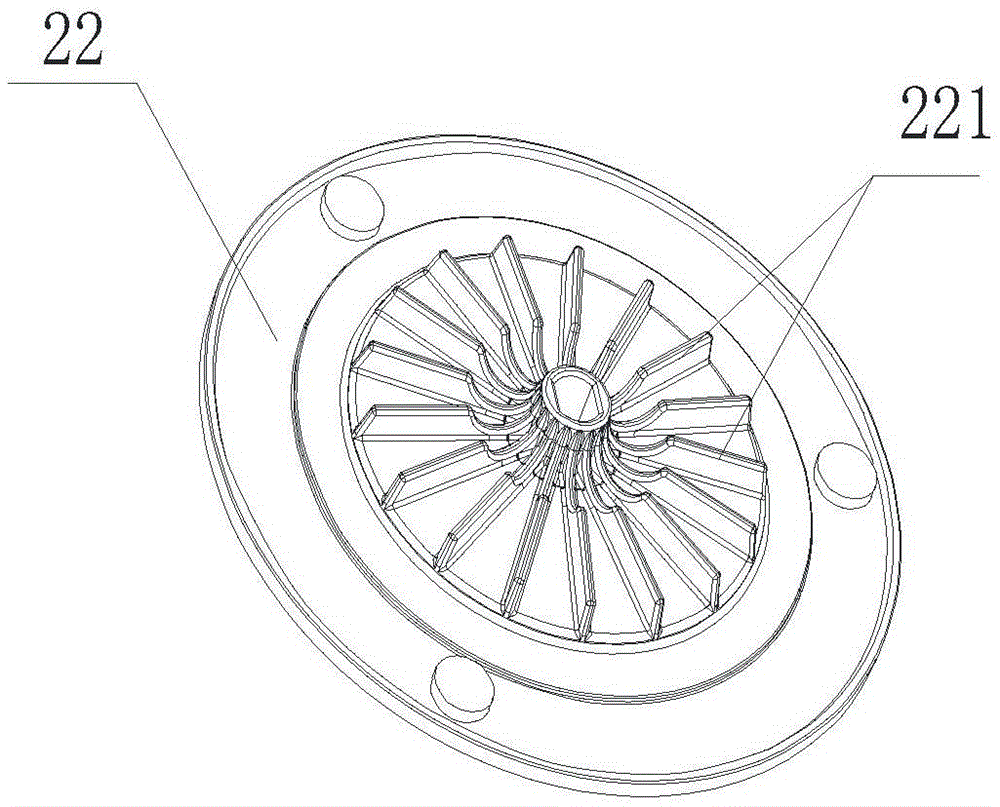

[0022] Such as figure 1 As shown, the centrifugal cutterhead includes a cutterhead body 22, the cutterhead body 22 is a disc, and the top surface of the cutterhead body 22 has several blades 221 with a certain height, and the cutterhead body 22 and the blades 221 are integrally formed. structure, the blades 221 are distributed in a divergent shape around the rotation centerline of the cutter head body 22 , and the blades are approximately perpendicular to the top surface of the cutter head body 22 .

Embodiment 2

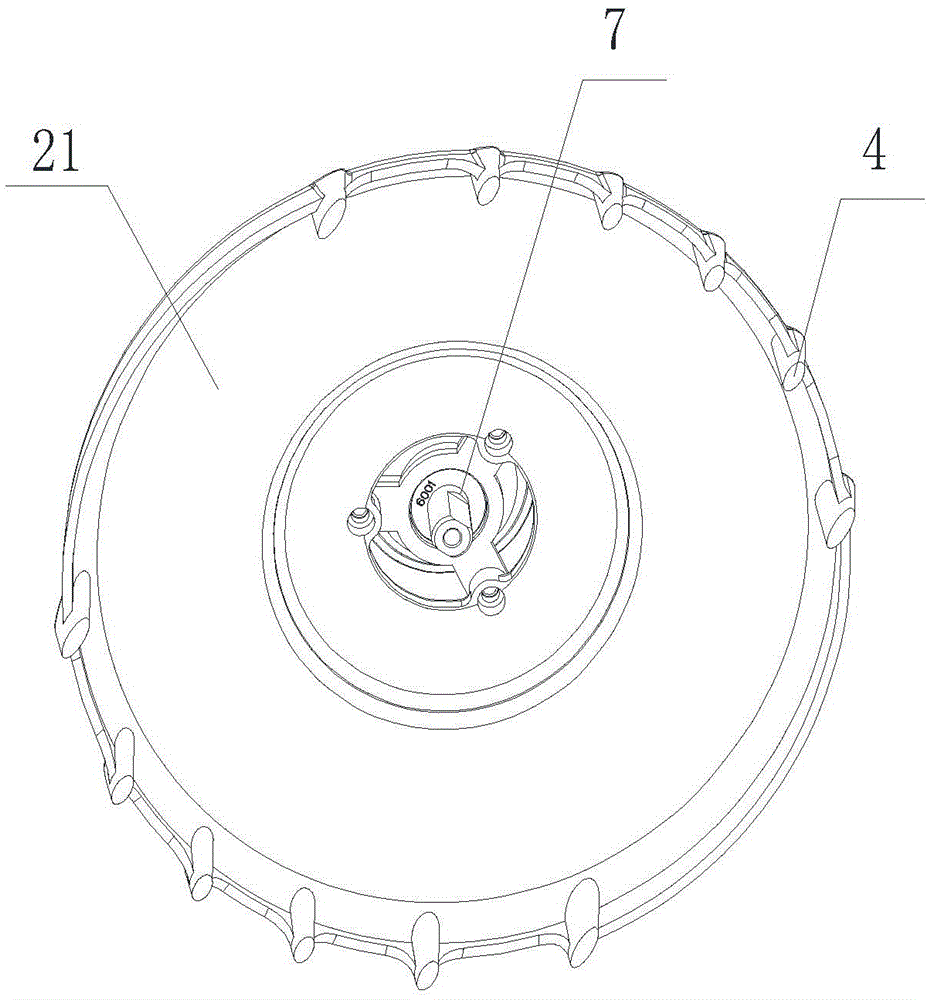

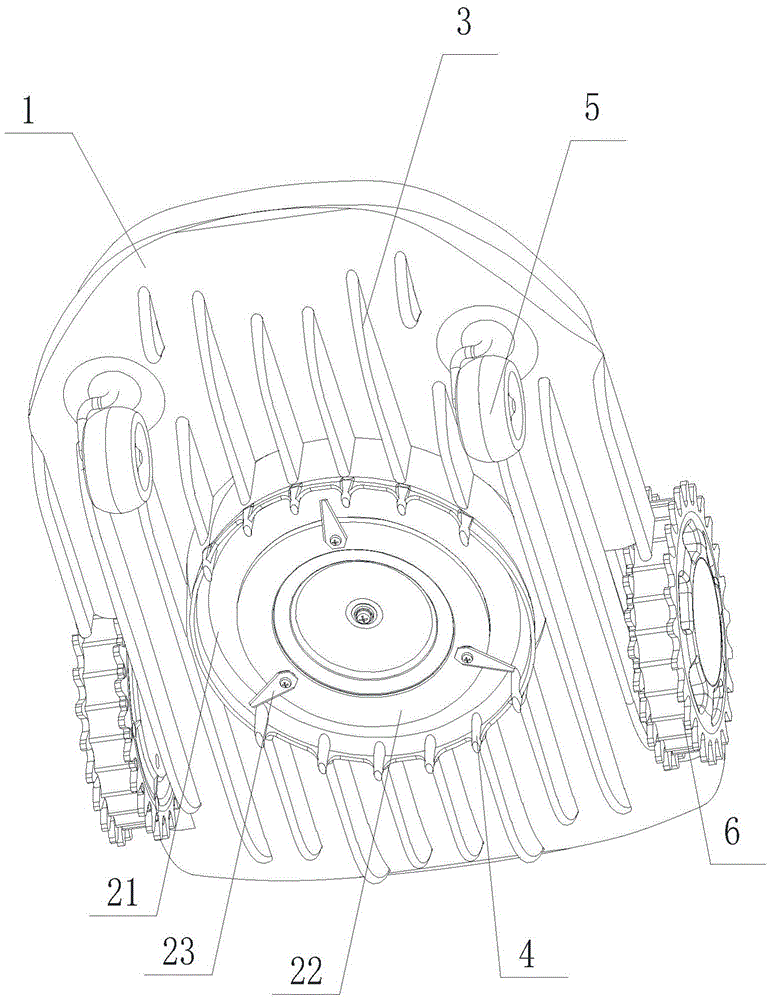

[0024] Such as Figures 2 to 6 As shown, the lawn mower includes a casing 1 and a blade assembly mounted on the casing 1. The blade assembly has a cutter head, and the casing 1 is equipped with a drive mechanism connected to the cutter head for driving the rotation of the cutter head. The disc is a centrifugal cutter disc as in Embodiment 1. The cutterhead frame 21 exposed to the bottom of the casing 1 is installed on the casing 1, the bottom surface of the casing 1 has a hole 12, the top of the cutterhead frame 21 has a cylinder 212 extending into the hole 12, and the cutterhead is positioned at the bottom of the cutterhead. Below the frame 21, the driving mechanism includes a motor 7 installed in the cylinder 212, and the output shaft of the motor 7 extends to the bottom of the cutter head frame 21 to be connected with the cutter head. The cylinder 212 extends into the hole 12 and is slidably matched with the casing 1 . The outer wall of the cylinder 212 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com