Lawn mower guards and lawn mowers

A protective device and lawn mower technology, which is applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of large resistance, potential safety hazards of the fence-type cover structure, and large labor costs, etc., and achieve reduction The effect of driving resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

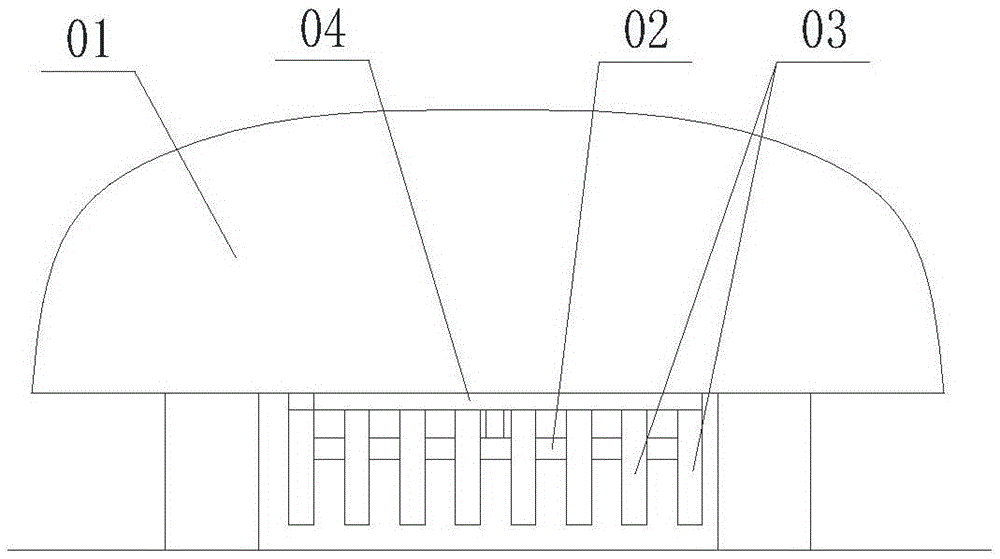

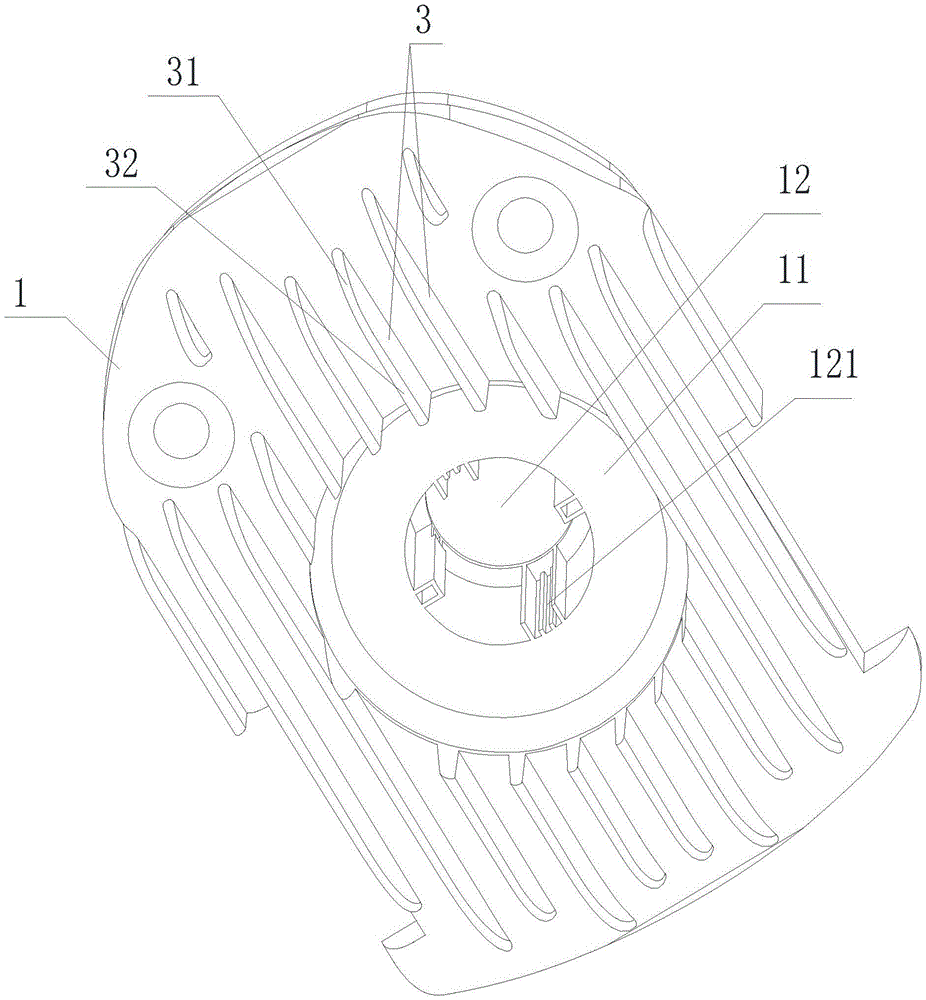

[0025] Such as image 3 with 4 Shown is an embodiment of the protection device for a lawnmower, wherein the lawnmower has a casing 1 and a cutterhead frame 21 that is installed on the casing 1 and exposed to the bottom surface of the casing 1, and the cutterhead frame 21 is provided with a Cutter 22, three uniformly arranged blades 23 are installed on the edge of cutter 22, drive motor is installed on cutter frame 21, the output end of drive motor is connected with cutter 22 and drives cutter to rotate, lawn mower protection device includes Some long lamellar ribs 3 that are arranged on the bottom surface of the casing 1 and some protective columns 4 that are arranged on the bottom surface of the cutter head frame 21; On the bottom surface of the shell 1, the ribs 3 surround the cutter head frame 21, and the protective column 4 surrounds the cutter head 22. The extension direction of the ribs 3 is consistent with the direction of travel of the lawn mower. Between two adjacent...

Embodiment 2

[0027] Such as Figures 3 to 5 Shown is an embodiment of a lawn mower, the lawn mower has a casing 1 and a cutter head frame 21 installed on the casing 1 and exposed below the bottom surface of the casing 1, the bottom surface of the casing 1 has a circular groove 11 The center of the circular groove 11 has a hole 12, the top of the cutter head frame 21 has a cylinder 212, the cutter head frame 21 is set in the circular groove 11, and the cylinder 212 extends into the hole 12 to slide and fit with the casing 1. The outer wall of the cylinder 212 is provided with a slider 213, and the inner wall of the hole 12 is provided with a chute 121 slidingly matched with the slider 213, so that the cutter head frame 21 can slide up and down relative to the casing 1, and a motor is installed in the cylinder 212. The output end of the motor is equipped with a cutterhead 22, and three evenly distributed blades 23 are installed on the edge of the cutterhead 22. The cutterhead 22 and the blad...

Embodiment 3

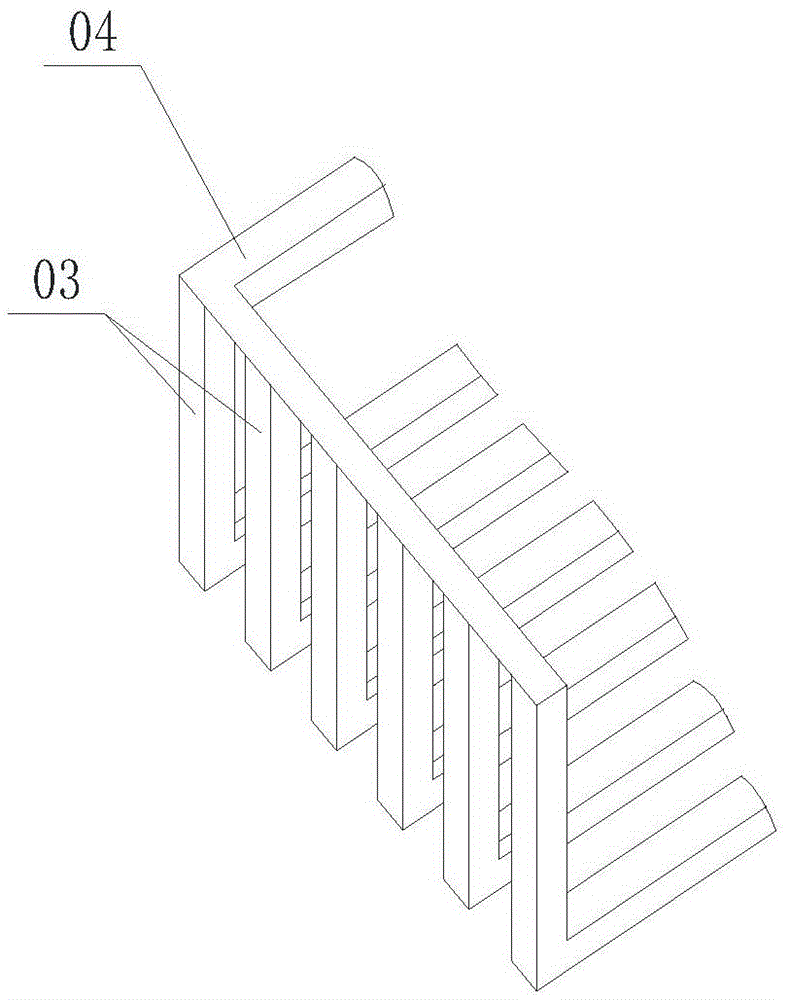

[0029] Such as Image 6 with 7 As shown, the difference from Embodiment 1 is that some or all of the ribs 3 on the bottom surface of the casing 1 are replaced by some protective columns 4 arranged in rows, and the arrangement direction of each row of protective columns 4 is the same as that of the lawn mower. The direction of travel during work is consistent, and there is a certain distance between two adjacent rows of protective columns 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com