Novel washing machine heating tube rubber pad mold

A washing machine and heating tube technology, which is applied in the field of rubber pad moulds for heating tubes of new washing machines, can solve the problems of no place for the storage of rubber materials and the inability to fix molded parts, and achieves the effects of avoiding waste, improving service life and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

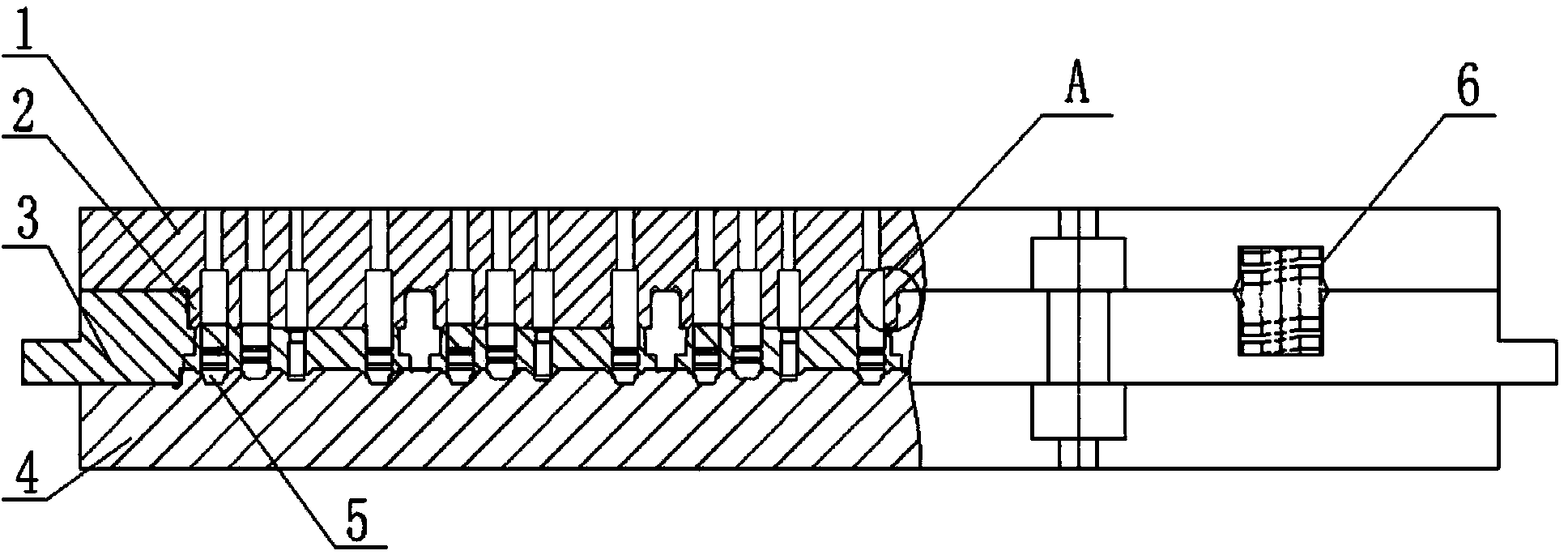

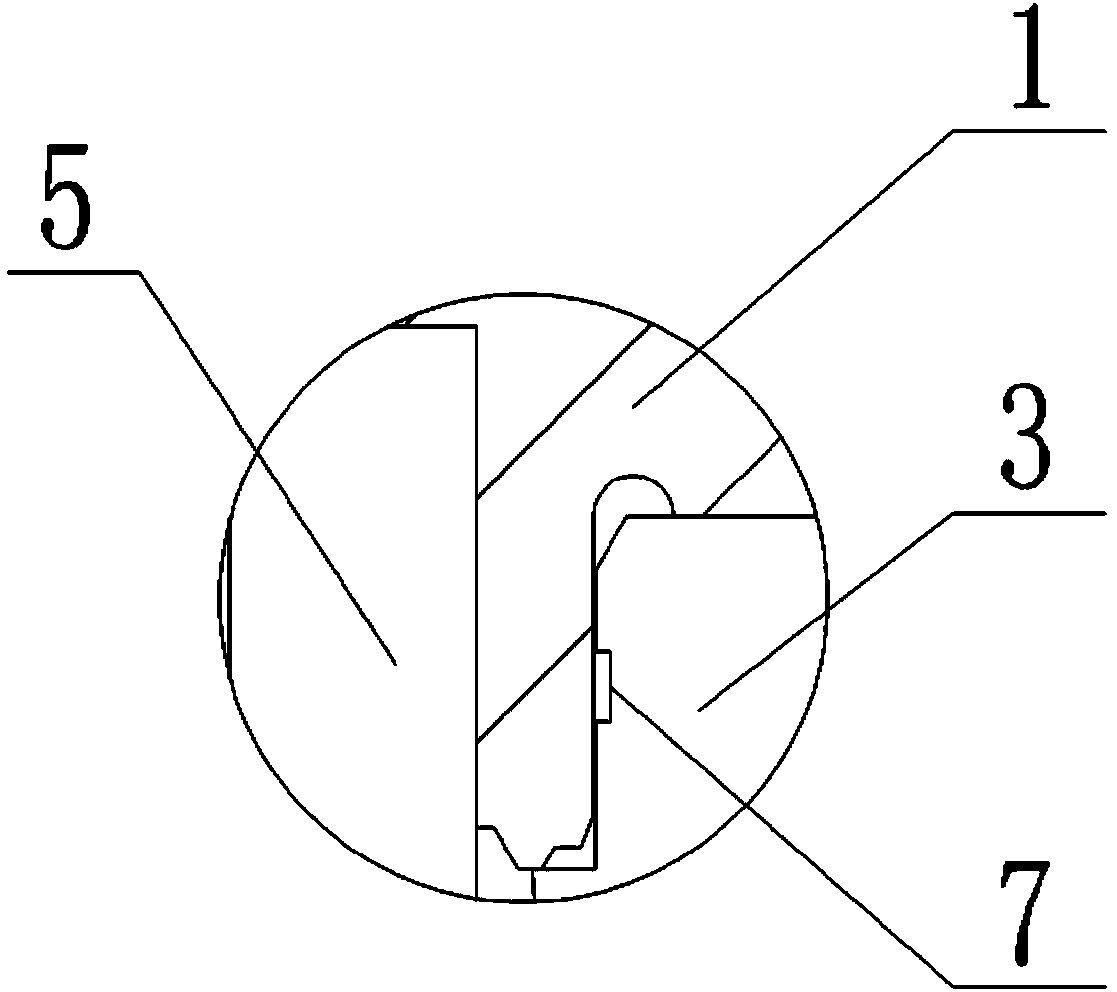

[0013] Such as figure 1 with figure 2 Shown is a new type of washing machine heating pipe rubber pad mold, which includes an upper mold 1, a middle mold 3 and a lower mold 4, and a material cup 2 is formed between the upper mold 1 and the middle mold 3, and the excess rubber can be stored in the material cup 2, to prevent excess rubber from affecting the mold; the cup 2 is provided with a core 5, which runs through the middle mold 3 and the lower mold 4, and the self-positioning of the mold core 5 prevents the mold core 5 from being damaged by the molding process. The medium pressure causes deformation; a spring 6 is provided between the upper mold 1 and the middle mold 3, which can effectively prevent the glue from flowing away from the plane of the lower mold; When the mold is opened, the flash is stuck on the middle mold 3 so that it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com