Primary extraction working face high-level suction tunnel gas extraction method

A technology for gas drainage and working face, which is applied in gas discharge, mining equipment, earthwork drilling and mining, etc. It can solve problems such as gas accidents, difficulty in functioning, and lack of gas, so as to prevent gas from exceeding the limit and increase the amount of gas drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This extraction method is realized through the following technical scheme:

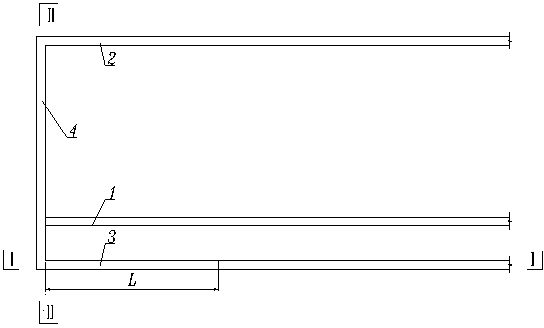

[0024] (1) Determine the initial caving (pressure) step distance L: the value of L is related to factors such as basic roof lithology, thickness and geological structure, generally 10-30m, and a few up to 50-70m.

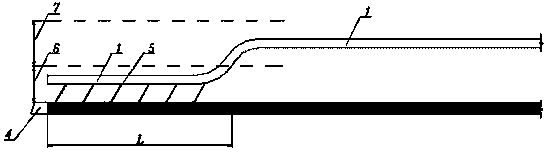

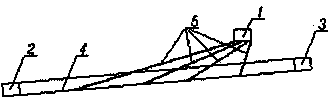

[0025] (2) Changing the 1st layer of the high extraction roadway: In order to make the high extraction roadway play a role in the initial recovery stage of the working face, the slope began to change when the construction high extraction roadway was 4 horizontal distances away from the cut hole and the remaining Lm. Adjust the level of the high pumping roadway from the original arrangement in the coal seam fissure zone 7 to be in the coal seam caving zone 6, that is, arrange the front section Lm of the high pumping roadway in the caving 6.

[0026] (3) Construction layer-penetrating drilling 5: set up a drilling site every 10m in the front Lm high pumping roadway, and construct 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com