Method for relieving pressure and eliminating outburst of ground butting well

A technology for ground docking and outburst elimination, applied in drilling equipment and methods, drilling equipment, earthwork drilling, etc., can solve problems such as easy artificially induced outburst, inability to perform regional pressure relief, and rapid desorption of reduced adsorption gas pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

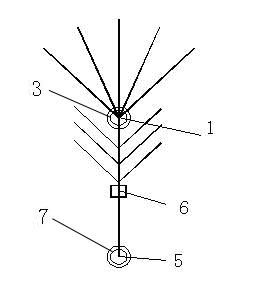

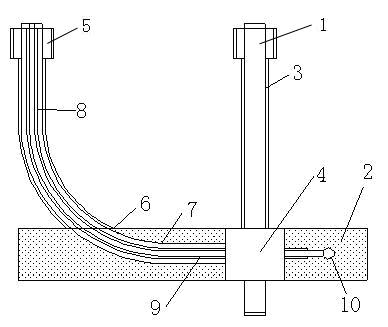

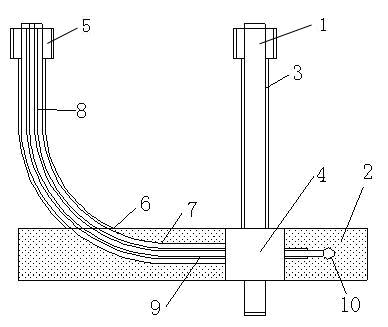

[0013] A method for pressure relief and outburst elimination of ground-connected wells, characterized in that: operate according to the following steps:

[0014] Step 1), establish a vertical well 1 for discharging coal powder, water and coal-bed methane, and collecting coal-water mixture, and install a gas production device to recover coal-bed methane; The casing 3 reinforces the vertical well 1, excavates the surrounding coal body in the coal seam 2 by means of mechanical or aerodynamic cavitation, and forms a cave 4 with a diameter ≥ 1.5m in the coal seam;

[0015] Step 2), establish a horizontal well 5 for directional docking with the vertical well 1, and rely on the coiled tubing 8 and the jetting operation tool to perform the jetting operation. The angle is determined according to the distance between the vertical well 1 and the horizontal well 5 in the design, the position of the deflection point of the vertical well 1, and the intersection of the horizontal well 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com