Magnetic control vibration isolation device

A magnetic control and vibration isolation technology, applied in vibration suppression adjustment, non-rotation vibration suppression, etc., can solve the problems of inability to meet the needs of precision instruments and equipment, deterioration of vibration of precision instruments and equipment, and poor vibration isolation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

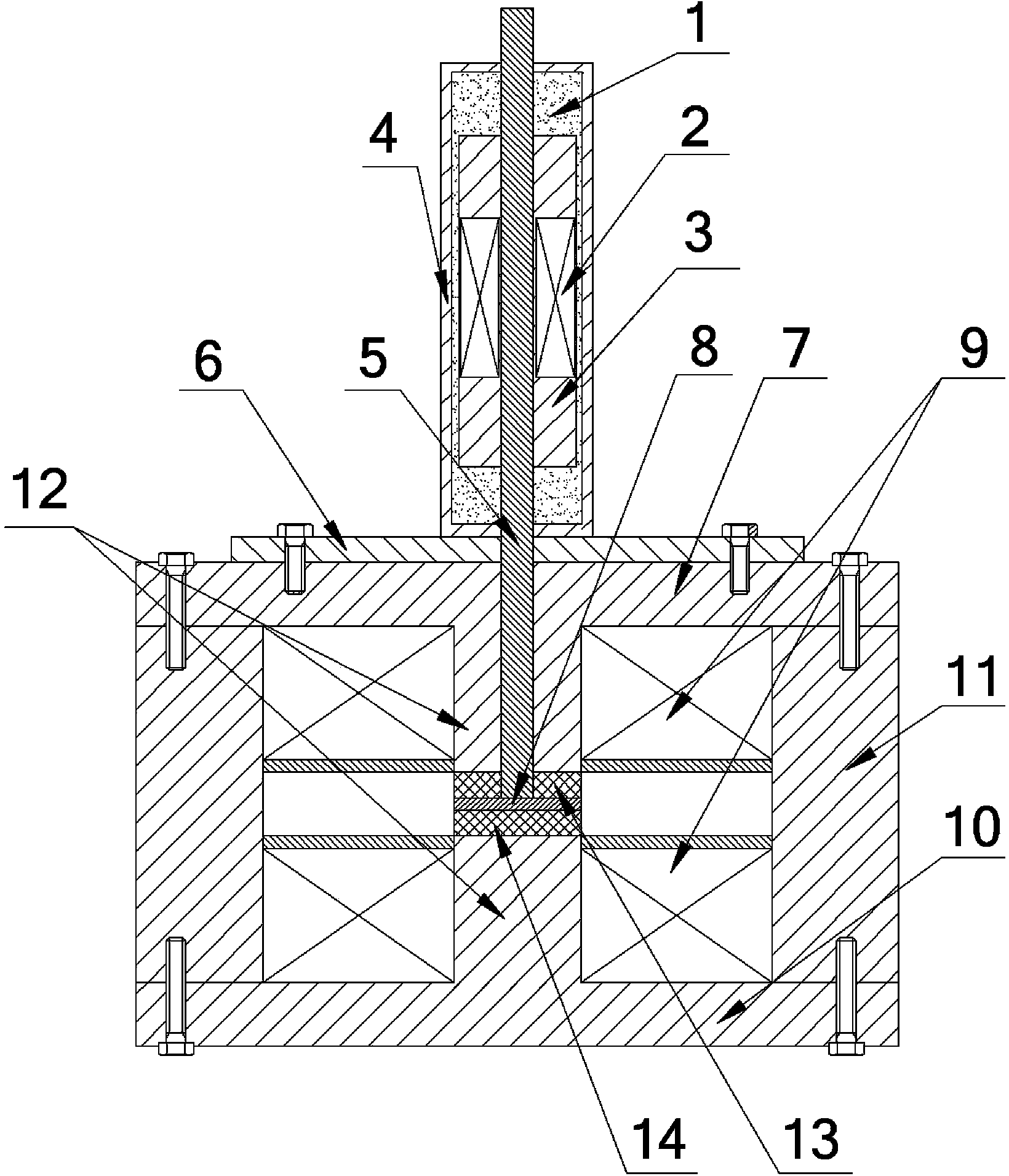

[0020] see figure 1 , is an embodiment of the magnetic control vibration isolation device, including a magnetic control damping device and a magnetic control elastic device, and the magnetic control damping device includes an outer sleeve 4 of a sealed structure, and the outer peripheral surface of the outer sleeve is cylindrical, And has a cylindrical cavity. The first iron core 3 is arranged in the inner cavity of the outer sleeve 4, the first iron core is cylindrical, the outer diameter of the first iron core 3 is smaller than the inner diameter of the outer sleeve 4, and the first iron core 3 is provided with an extension An annular groove extending in the circumferential direction of the first iron core, the annular groove is located in the middle section of the first iron core 3, the first excitation coil 2 is arranged in the annular groove, and the outer surface of the first excitation coil 2 is passed through epoxy Resin seal. A connecting rod 5 passes through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com