Multi-tube corn thresher

A technology of thresher and corn, applied in the direction of threshing equipment, agricultural machinery and implements, application, etc., to achieve the effect of improving threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

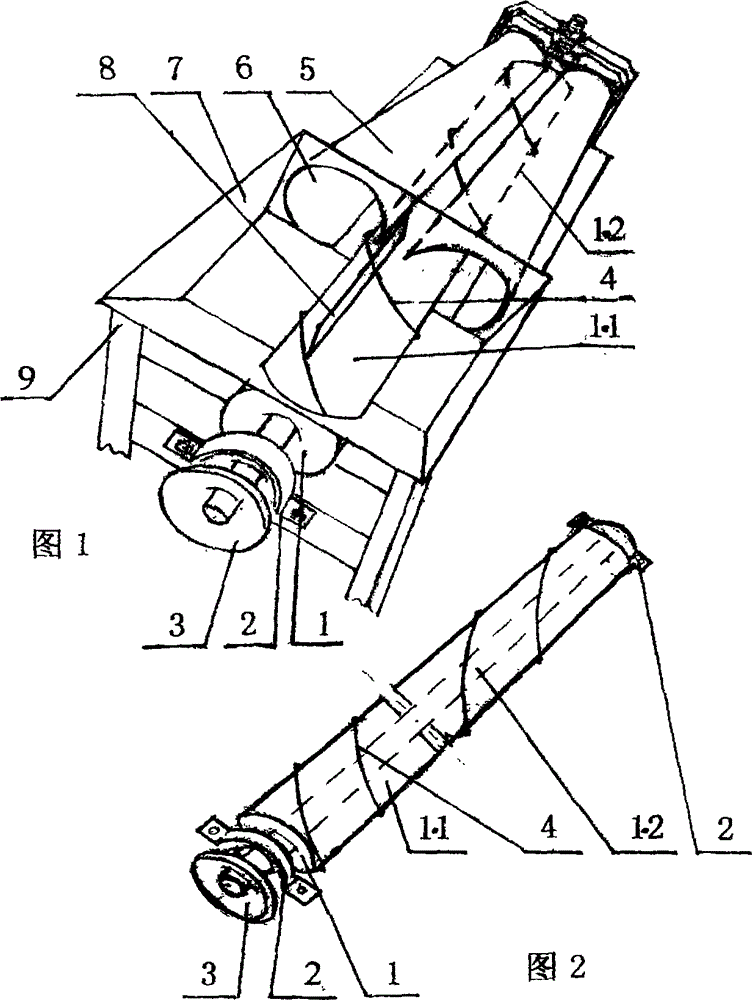

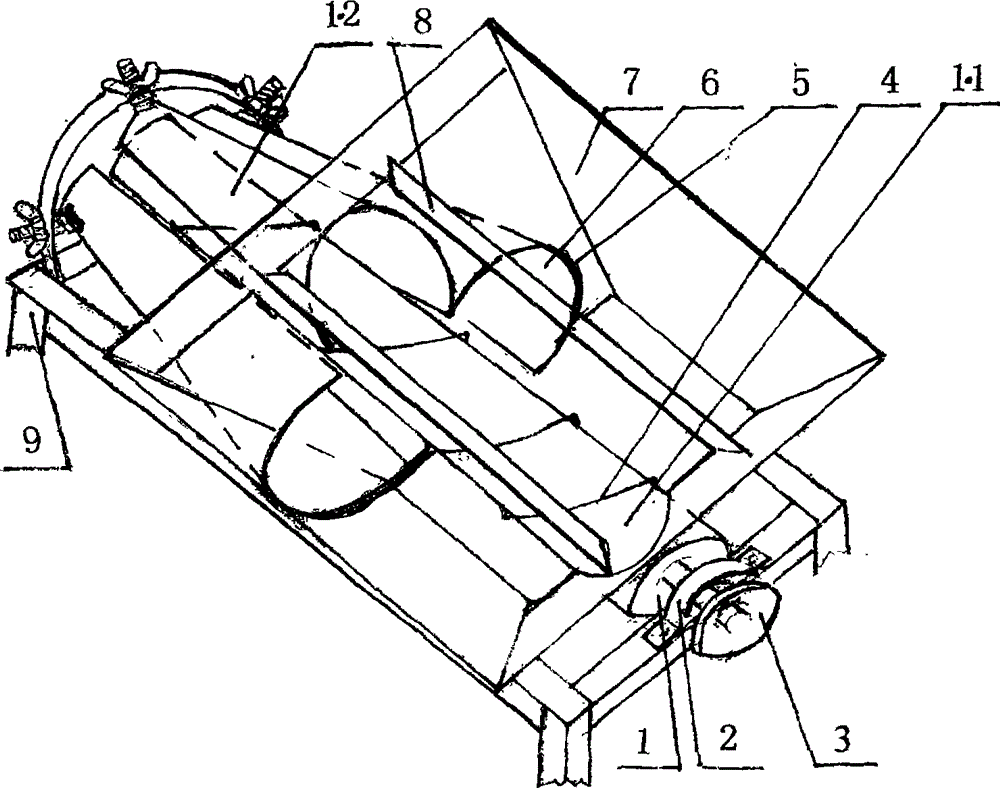

[0019] Horizontal multi-tube corn thresher

[0020] Such as Figure 1-3 As shown, the shafts at both ends of the drum (1) with spiral ribs (4) fixed on the surface are installed on the frame (9) through the bearing seat (2), and the drum (1) is divided into a conveying section (1.1) and a threshing section. Section (1.2), feeding hopper (8) is installed on the upper part of the feeding section (1.1), and the feeding section (1.1) is the bottom of the feeding hopper (8), which constitutes a feeding device. The upper part of the drum threshing section (1.2) and the two A threshing concave plate (7) is installed on the side to form a threshing device, and a partition plate (8) is fixed between each threshing concave plate (5) on one side where the feed hopper (7) is connected with the threshing concave plate inlet (6).

[0021] Install two threshing concave plates (5) on the upper part or both sides of the threshing section (1.2) of the drum (1), and install the feeding hopper (...

Embodiment 2

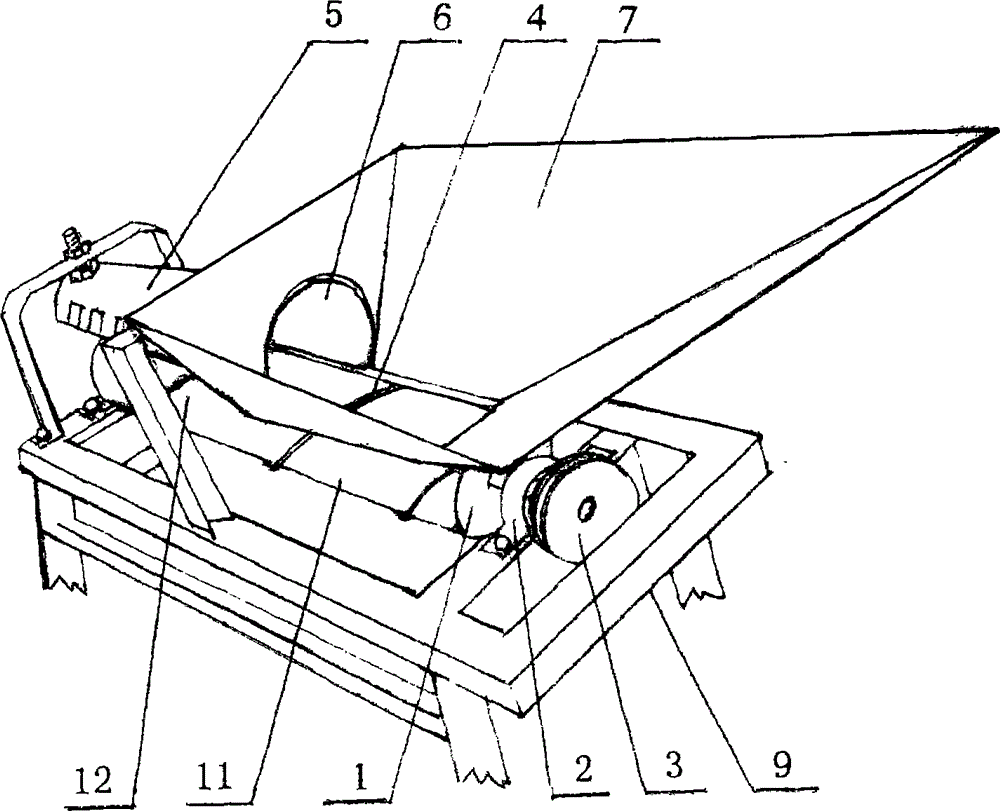

[0024] Horizontal single tube corn thresher

[0025] Such as Figure 4-5 As shown, install a threshing concave plate (5) on the upper part of the threshing section (1.2) of the drum (1), or install a threshing concave plate (5) on its right or left side, and install a threshing concave plate (5) on the upper part of the drum feeding section (1.1). A feed hopper (7) is installed to form a horizontal single-pipe corn thresher. The main technical features of the horizontal single-tube corn thresher are still: the drum (1) is divided into a feeding section (1.1) and a threshing section (1.2), and a feeding hopper (8) is installed on the upper part of the feeding section (1.1), and the feeding The section (1.1) is the bottom of the feeding hopper (8), which constitutes the feeding device. A threshing concave plate (5) is installed on the upper or right or left side of the drum threshing section (1.2), which constitutes the threshing device. The feeding hopper (7) There is only on...

Embodiment 3

[0027] Vertical multi-tube corn thresher

[0028] Such as Figure 6-8 As shown, different from the horizontal corn thresher, the drum (1) of the vertical multi-tube corn thresher is installed vertically in the frame (9), and the front end bearing seat (2) is installed between the conveying device and the threshing device. Between, drum pulley (3) is installed in the lower end of drum (1), installs four or three or two or a threshing concave plate (5) around the threshing section (1.2) of drum (1). Constitute a vertical four-pipe, three-pipe, double-pipe, single-pipe corn thresher, double-duplicate the vertical three-pipe, four-pipe corn thresher unit, and make a vertical six-pipe, vertical eight-pipe corn thresher or vertical multi-pipe corn thresher Tube corn thresher. The conveying section (1.1) of the vertical multi-tube corn thresher is vertically installed and fixed in the feed hopper (7) above the frame (9), and its main function is to remove plugs and plugs at the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com