Combing member and pet comber

A comber and component technology, which is applied in the field of pet groomers, can solve problems such as the inability to remove loose hair, and achieve the effect of removing loose hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

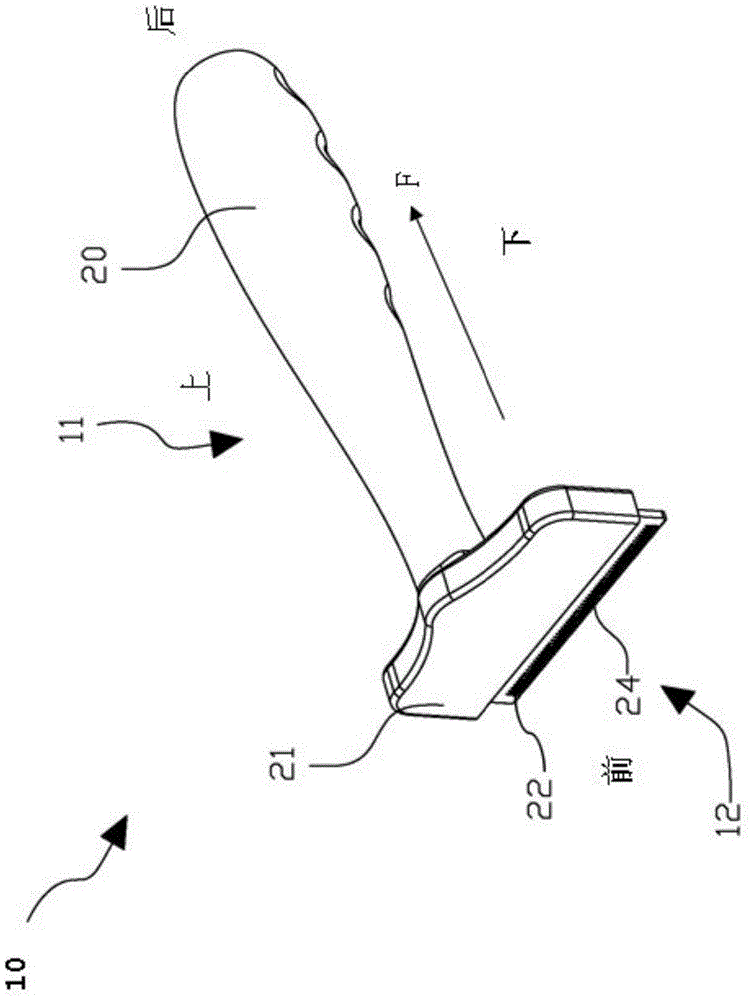

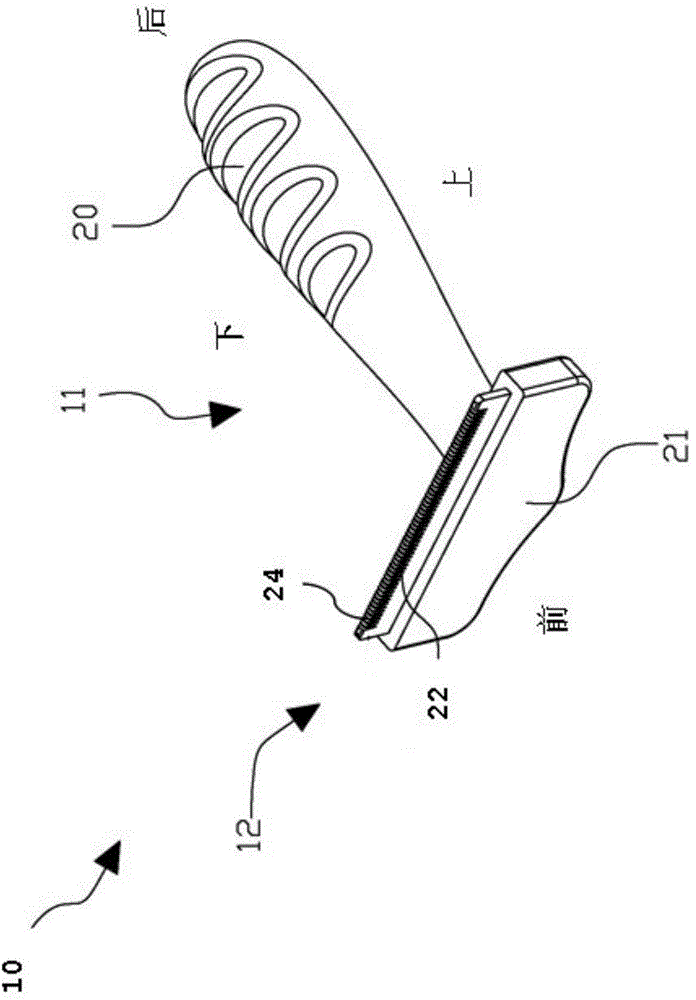

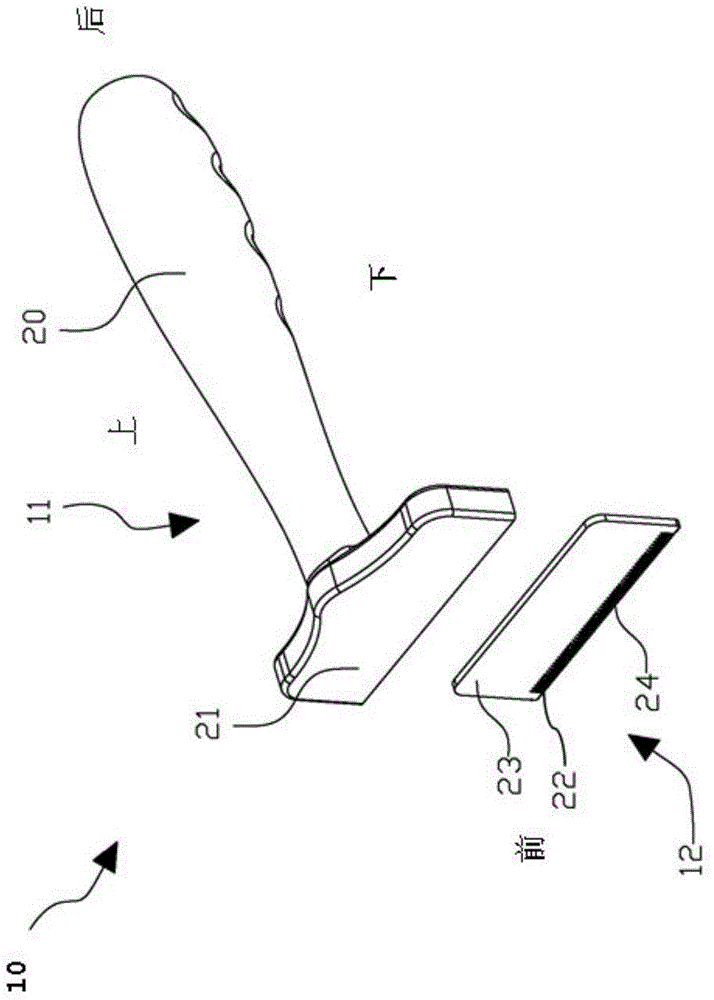

[0032] Such as Figure 1~6 As shown, the pet groomer 10 includes a handle portion 11 and a grooming member 12 .

[0033] The handle portion 11 is provided for the operator's hand to grasp and includes a handle 20 and a front end piece 21 . The shape and size of the handle 20 should be convenient for the operator to hold firmly and prevent slippage. Front end part 21 is positioned at the front end of handle 20 (as figure 1 ), for combining the handle portion 11 and the combing member 12. The front end piece 21 and the handle 20 can be made into one body, or can be divided into two independent parts and then assembled together.

[0034] The carding member 12 has a flat plate shape and is made of metal material. The combing member 12 includes a plurality of comb teeth 22 , a base 23 , a friction layer (not shown), an edge guard 34 and an edge guard 35 .

[0035] Each comb 22 comprises a comb tip face 24, a comb side 25, a comb side 26, a comb back 27 and a comb face 28 (see ...

Embodiment 2

[0044] Such as Figure 7 As shown, the second embodiment provides a combing member 120, and the combing member 120 is also flat plate like the combing member 12 in the first embodiment.

[0045] The only difference is that, in the second embodiment, an included angle C greater than 90 degrees is formed between the dedendum surface 129 of the combing member 120 and the comb surface 128 (see Figure 7 (B)). All root surfaces 129 lie in the same root plane. In this case, the vertical distance from the center point of the comb tooth tip surface 124 to the intersection line of the comb tooth comb back surface 127 and the tooth root surface 129 is relatively short, and the center point of the tip surface 124 to the comb tooth comb surface 128 and the tooth root surface The vertical distance of the intersection line of 129 is relatively long (see Figure 7 (D)), the tooth root surface is not perpendicular to the extension direction of the comb, and the intersection line between th...

Embodiment 3

[0047] Such as Figure 8 As shown, in the third embodiment, the cross-sectional shape of the combing member 220 can also be made into a stepped shape like the cutter head of the electric clipper (such as Figure 8 (B)), and the comb surface 228 is made into an arc shape, as Figure 8 As shown in B, the tooth root surface 229 is inclined, not perpendicular to the extension direction of the comb teeth, and forms the edge of the cutter head on the back side of the comb. The tooth comb surface 228 and the base comb surface 232 are also roughened, with a roughness of about 0.8-1.6 μm. When the combing member 220 of the third embodiment is used to comb the hair of pets, the edge of the cutter head only moves along the combing surface, and is not used to comb away loose hairs.

[0048] Such as Figure 8 As shown in (C), the combing member 220 includes a plurality of comb teeth 222 , a base 223 , an edge guard 234 and an edge guard 235 . Wherein, the base 223 is divided into a low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com