A hydraulically controlled swing-open check valve

A one-way valve and hydraulic control technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of one-way valves with few spools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

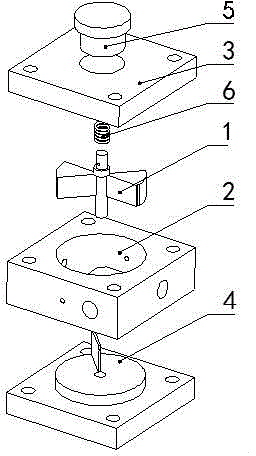

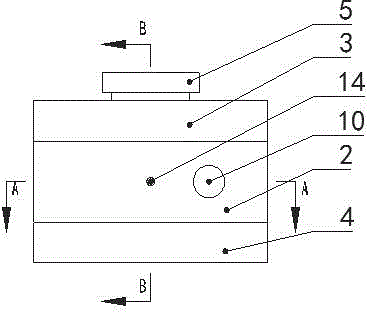

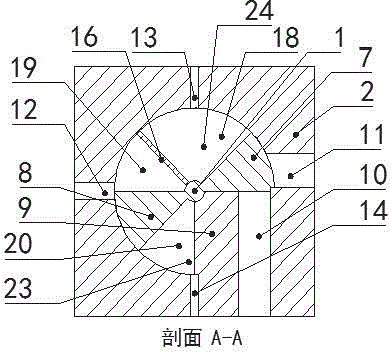

[0020] Such as Figure 1 to Figure 4 As shown, the hydraulically controlled swing-open check valve of the present invention mainly includes a valve core 1 , a valve body 2 , a first end cap 3 , a second end cap 4 , a torsion spring 6 and an adjusting nut 5 . The first end cover 3 is fixedly connected to one end of the valve body 2, the first end cover 3 and the valve body 2 are sealed by a sealing ring, and a clearance fit is formed between the first end cover 3 and the inner wall of the valve body 2, the second The second end cover 4 is fixedly connected with the other end of the valve body 2, and the second end cover 4 and the valve body 2 are sealed and connected by a sealing ring, and a clearance fit is formed between the second end cover 4 and the inner wall of the valve body 2 . The outer wall of the valve core 1 is provided with a first stopper...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap