An installation guide rail and a power distribution device with the installation guide rail

A technology for installing guide rails and guide rails, applied in substation/switch layout details, electrical components, rack/frame structure, etc., can solve the problems of low efficiency and difficulty in installation and disassembly of control boxes and cabinets, and achieve economical and economical disassembly. The effect of reducing the number of screws and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

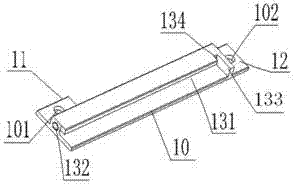

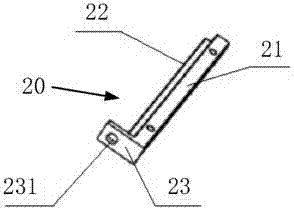

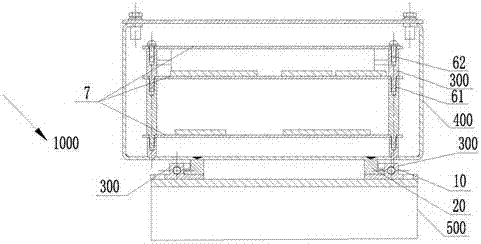

[0027] see figure 1 and figure 2 , which are respectively a schematic diagram of the overall structure of the first guide rail assembly of the embodiment of the present application and a schematic diagram of the overall structure of the second guide rail assembly of the embodiment of the present application. As shown in the figure, the installation rail includes a first rail assembly 10 and a second rail assembly 20 .

[0028] In a preferred embodiment, the first rail assembly 10 includes a guide portion 131 , a first positioning portion 11 and a second positioning portion 12 . The guiding part 131 includes a bottom wall, an upper wall and a supporting part connecting the bottom wall and the upper wall. The bottom wall and the upper wall are parallel to each other, and the supporting portion is perpendicular to the supporting portion of the bottom wall and the upper wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com