Pipe connection device

A pipe connection and connection system technology, applied in the direction of flange connection, adjustable connection, pipe/pipe joint/pipe fitting, etc., can solve problems such as leakage, increased assembly cost, and danger to users of toxic media equipment, and achieve the goal of improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

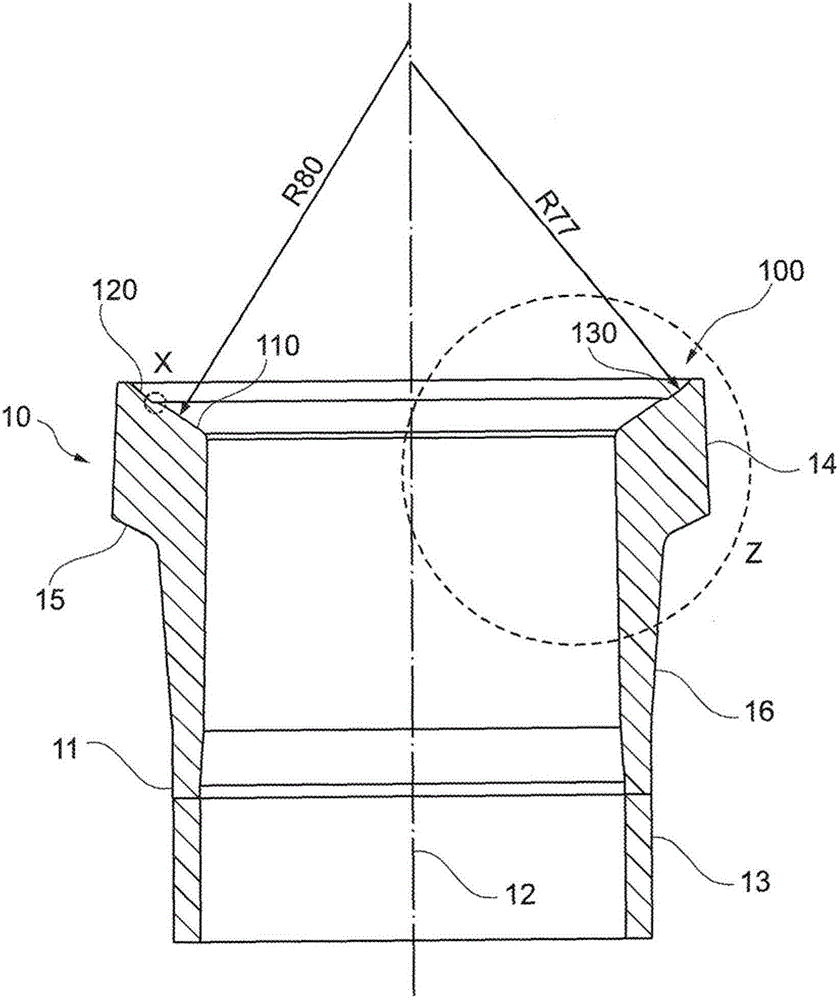

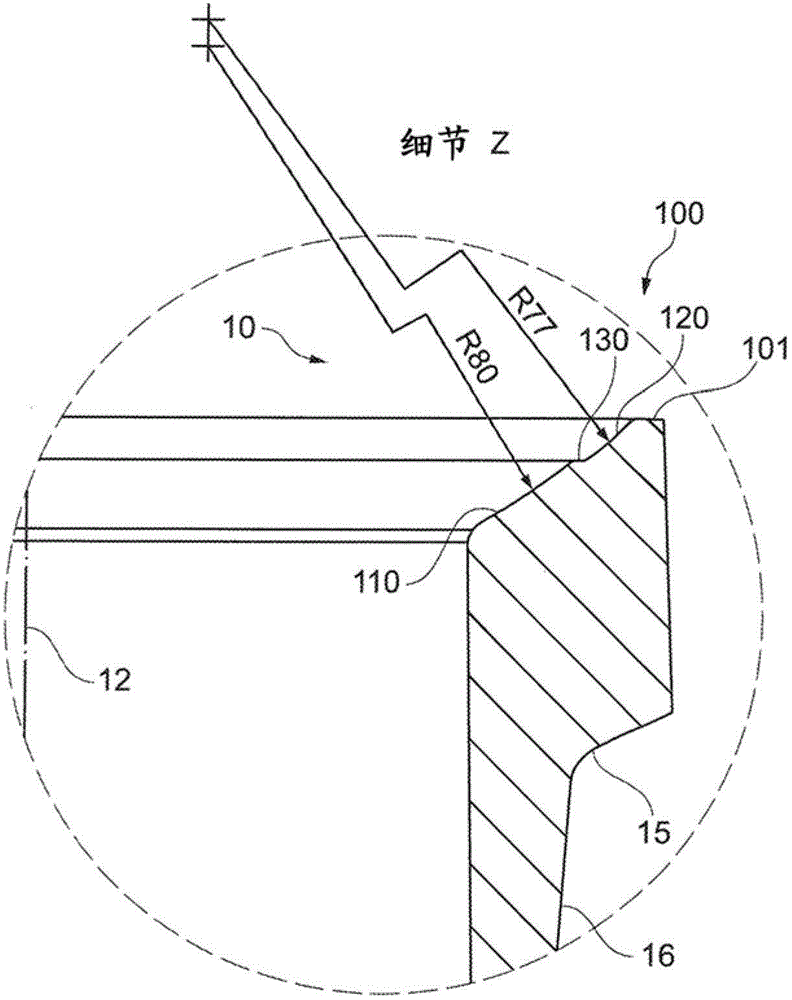

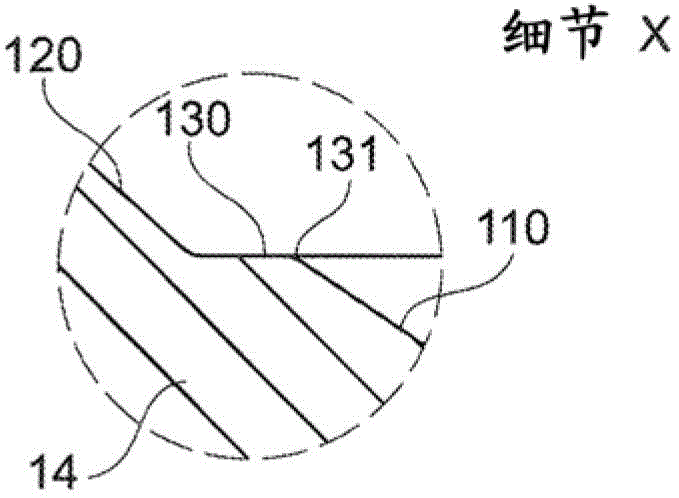

[0025] figure 1 A cross-sectional view of the end of one pipe is shown. exist figure 1 The cross-sectional views shown in may relate to the ends of straight or curved pipes or may relate to T-pieces, Y-pieces, four-branched pipes, six-branched pipes or other elements known per se for constructing pipe networks of a single connector.

[0026] The pipe 10 has a longitudinal section 13 with a substantially constant wall thickness and a parallel outer contour. The longitudinal section 13 serves either to convey the fluid flowing in the interior of the pipe 10 in a straight line or to move the figure 1 Adapt the fittings at the ends shown in to one of the piping elements described above.

[0027] The first longitudinal section 13 merges with a second longitudinal section 16 into the carrier 100 . The inner and / or outer walls of the second longitudinal section 16 may be inclined outwardly relative to the first longitudinal section 13 by a small number of degrees. This results ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com