Method for operating an electrolysis system and electrolysis system

A technology of electrolysis system and electrolysis cell, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of increasing the cost of electrolysis process, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

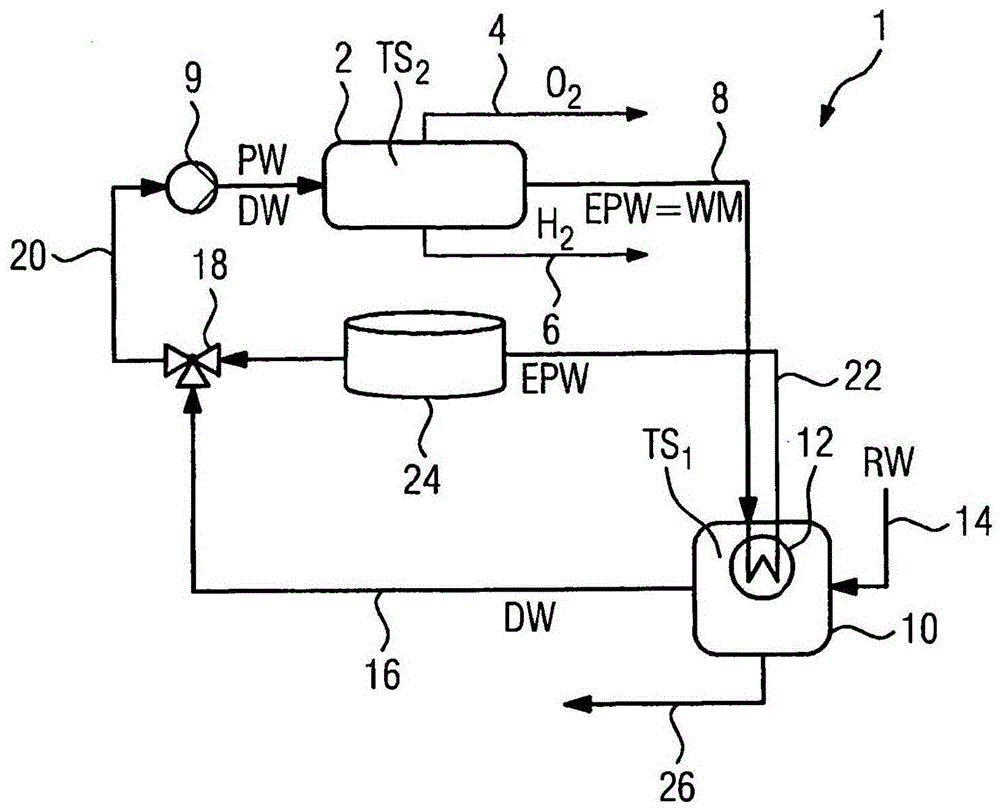

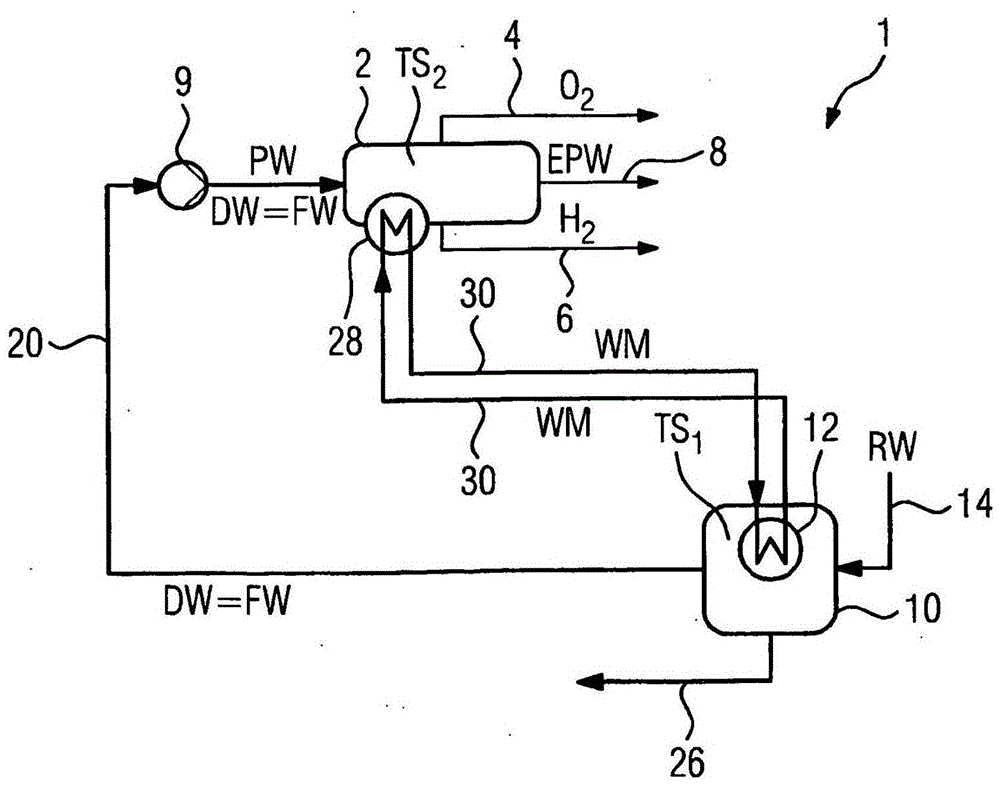

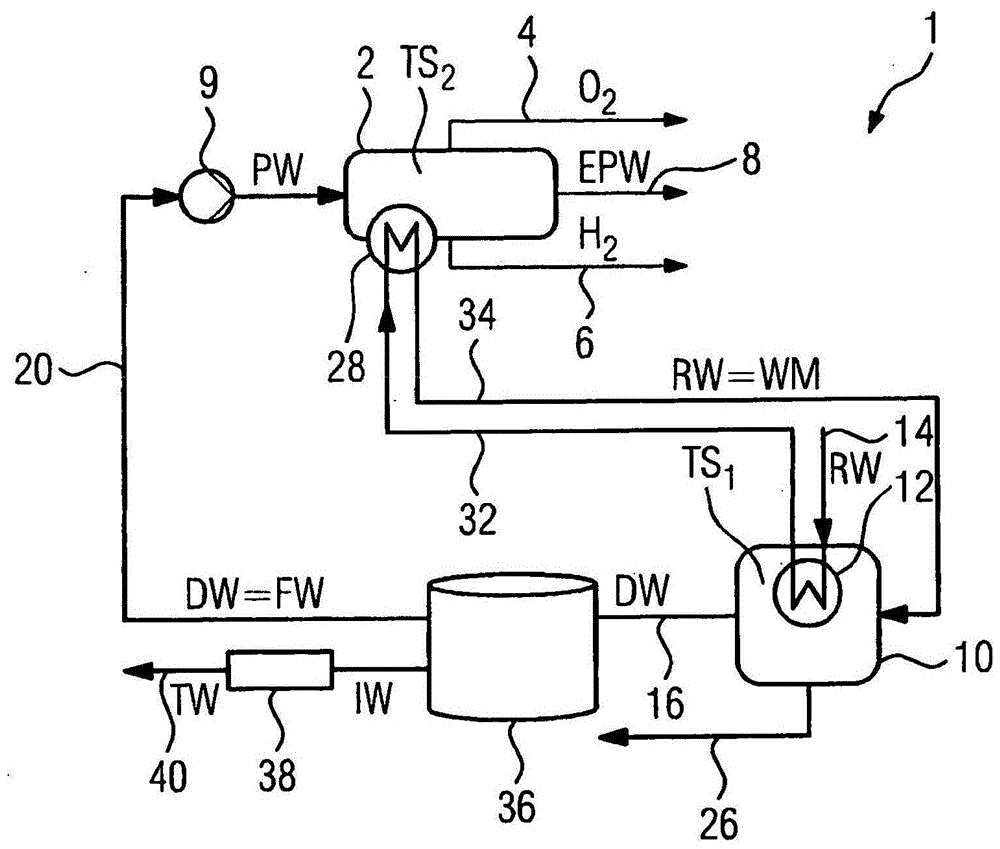

[0046] exist figure 1 An electrolysis system 1 with a PEM electrolysis cell 2 for generating hydrogen H2 and oxygen O2 is shown in . In the example shown, high-pressure electrolysis is carried out. However, the PEM electrolysis cell 2 can also be operated at atmospheric pressure.

[0047] The components of the PEM electrolysis cell 2 are a proton-permeable polymer membrane (Proton-Exchange-Membrane proton exchange membrane) not shown in detail here, which is connected on both sides to electrodes (anode, cathode) coated with catalyst. ) in contact. An external voltage is applied to the electrodes and water is delivered on the anode side of the PEM electrolysis cell 2 . Oxygen, electrons, and positively charged hydrogen ions are formed when water is split. The hydrogen ions diffuse through the proton-conducting membrane to the cathode side, where they combine by means of electrons from the external circuit to form hydrogen molecules H2. From the PEM electrolysis cell 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com