Installation tooling and assembly method of permanent magnet with array structure

A technology of array structure and installation tooling, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems of personal danger, permanent magnet block damage, inconvenient assembly and maintenance work, etc., so as to improve safety, facilitate accurate judgment, and ensure accurate The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

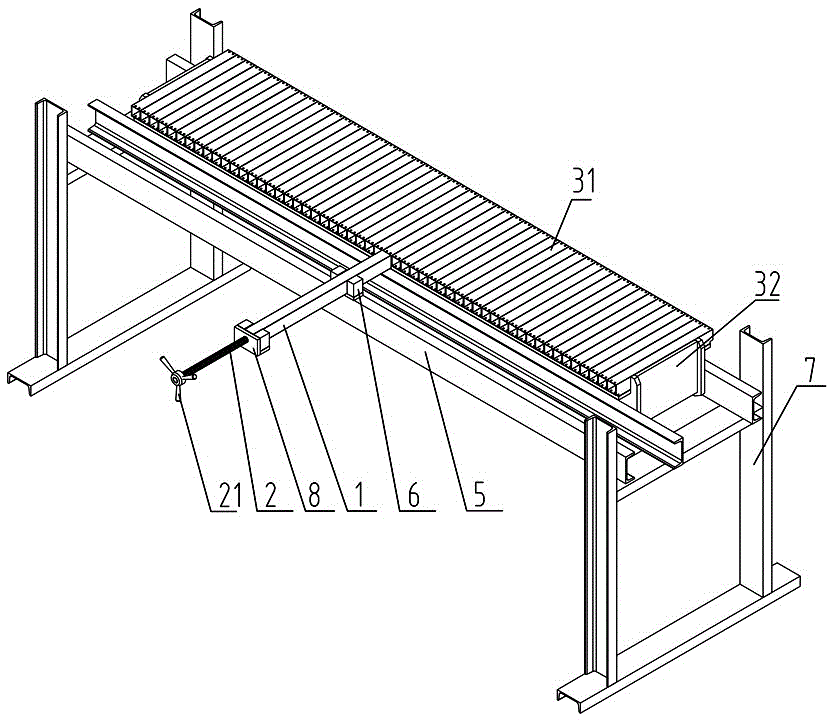

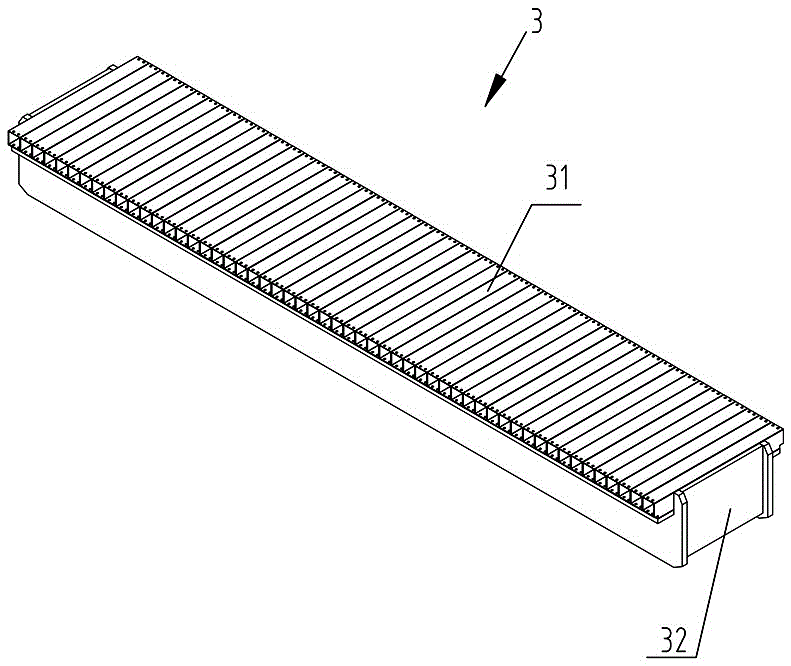

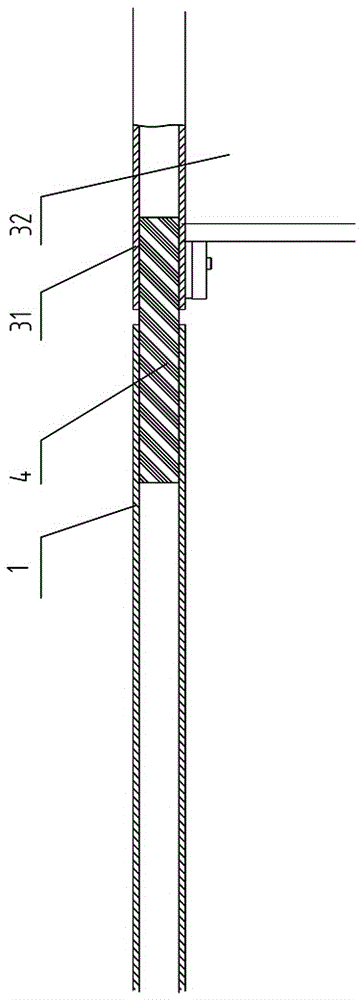

[0029] Such as Figure 1 to Figure 4 As shown, the installation tooling of the permanent magnet with an array structure in this embodiment includes a guide sleeve 1 and a pusher 2, the guide sleeve 1 is connected to the installation pipe 31 of the permanent magnet 3, and the installation pipe 31 is adapted to the permanent magnet block 33 Square tube, the pusher 2 is used to press the permanent magnet block 33 in the guide sleeve 1 into the installation tube 31, one end of the pusher 2 is sleeved in the guide sleeve 1 and can push the guide sleeve 1 along the length direction of the guide sleeve 1 The permanent magnet block 33 inside. The array structure permanent magnet assembly is assembled from unit permanent magnet blocks 33 whose magnetization direction changes according to a certain rule. It is a multi-period arrangement of Hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com