Automatic bottle stop control device for full-automatic bottling line

A control device and filling line technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as excessive accumulation of bottles, shutdown, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

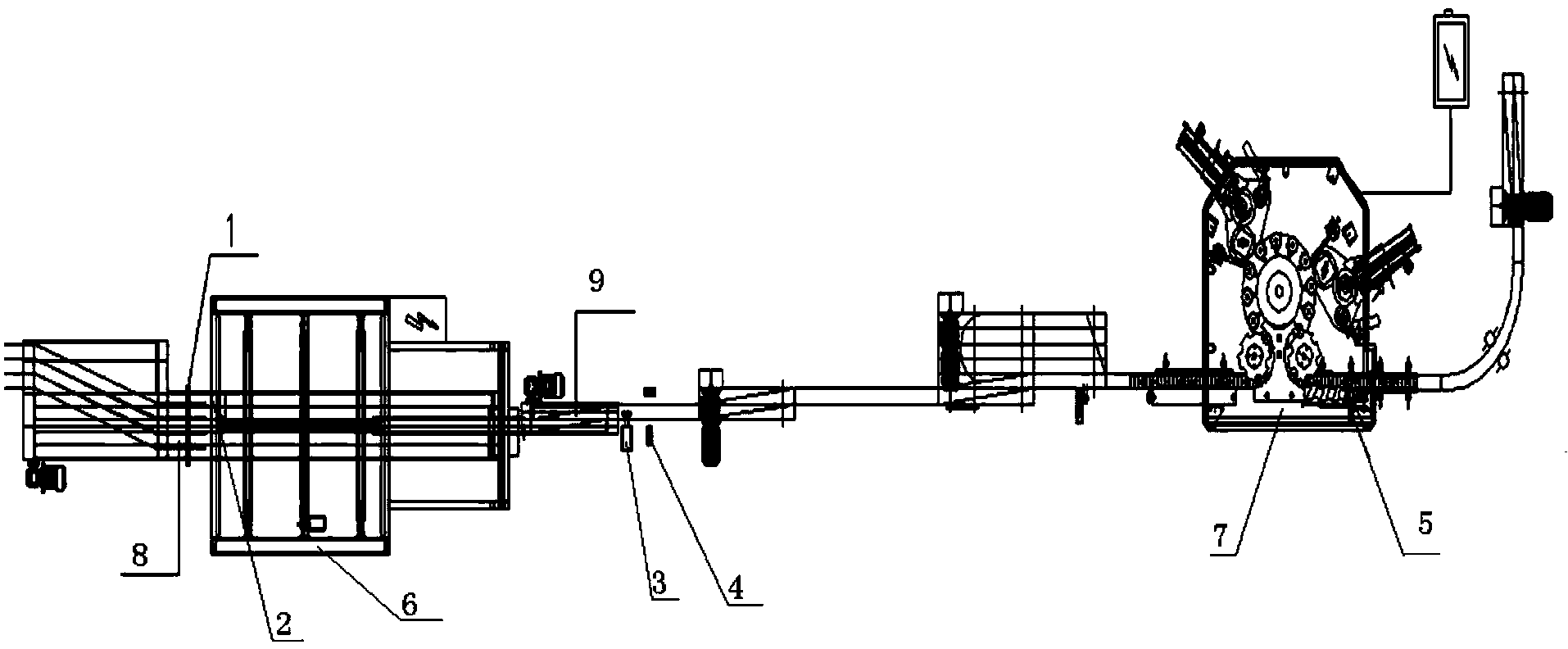

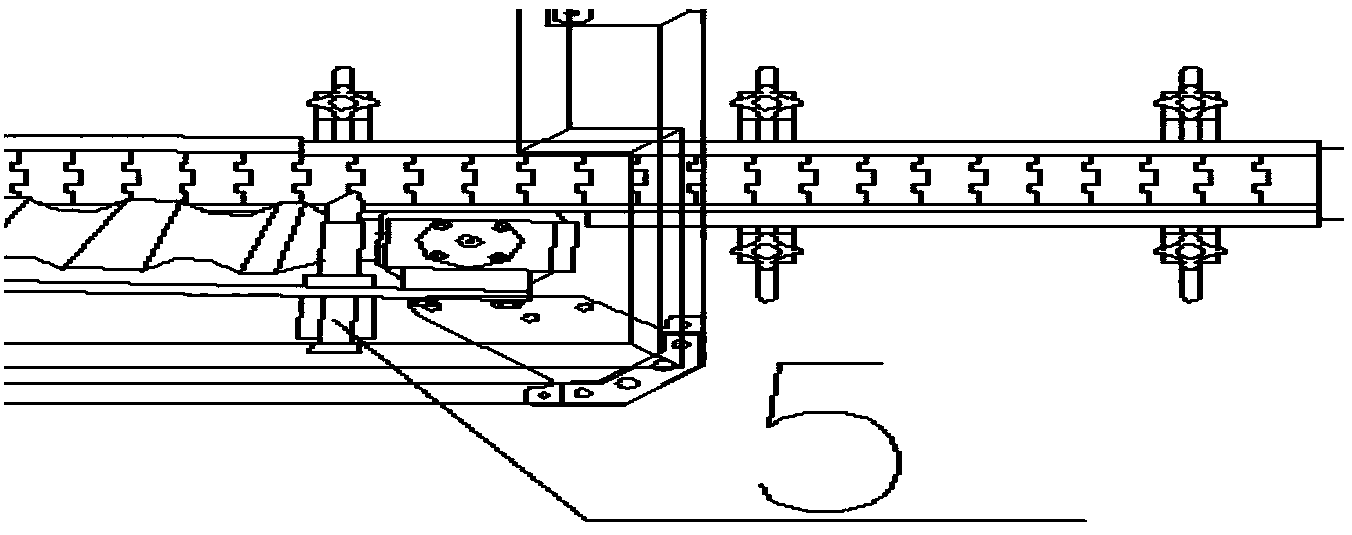

[0016] like figure 1 , 2 As shown, an automatic bottle blocking control device for a fully automatic filling line, comprising a bottle stopper 3, a bottle stopper 25, a photoelectric cell 2, a photoelectric cell 24, and three baffle plates 1, the The bottle stopper one 3 is installed on the front end of the bottle splitter 6 inlet conveyor belt 9, and the bottle stopper two 5 is installed at the entrance of the labeling machine 7; The control circuit of the bottle machine 6 is connected as the starting signal of the bottle stopper 13; the photocell 24 is installed on the front end of the bottle stopper 13 of the bottle splitter, and is connected to the control circuit of the labeling machine 7, which is the bottle stopper 25 The starting signal; the three shading plates 1 are arranged at the photocell 1 and 2.

[0017] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com