A kind of drainage method of coalbed methane well

A coalbed methane well and coalbed methane technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low liquid production, slow drainage and analysis time, small pressure drop funnel area, etc., and achieve high The effect of daily gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

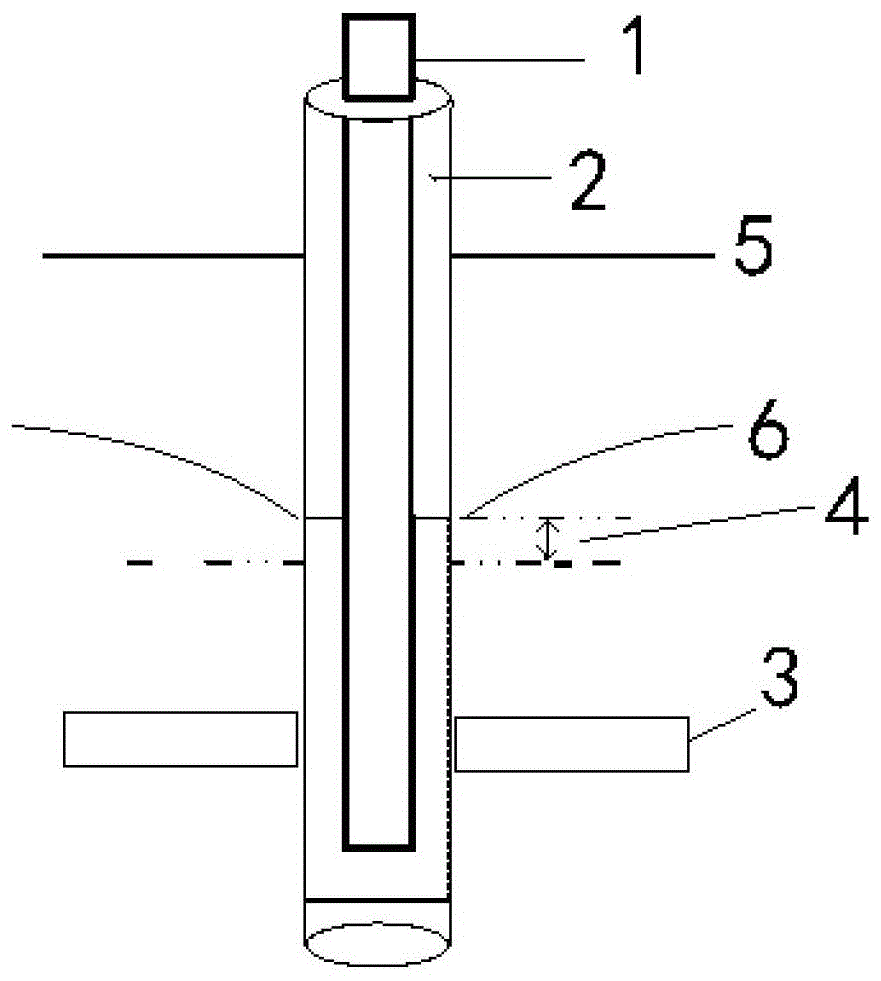

[0018] Embodiment 1: as figure 1 As shown, a coalbed methane well drainage method, the oil pipe 1 is in the wellbore 2; the coal seam section 3, the analytical pressure 4, the initial pressure of the coal seam 5, and the pressure drop funnel curve 6;

[0019] On the area of the pressure drop funnel curve 6, since the analytical pressure 4 is less than the initial pressure 5 of the coal seam, the coalbed methane will analytically migrate from the direction of high pressure to low pressure;

[0020] The well depth is 1200 meters, the initial pressure of the coal seam is 7MPa, and the analytical pressure (that is, as the downhole flow pressure decreases, the coalbed methane begins to be decomposed from the adsorption state in the coal rock to the free state and migrates to the wellbore. The bottom hole flow pressure at this time is called Analytical pressure) is 2.5MPa, according to the "continuous and slow" control idea, the dynamic fluid level drops by 3 meters per day, and i...

Embodiment 2

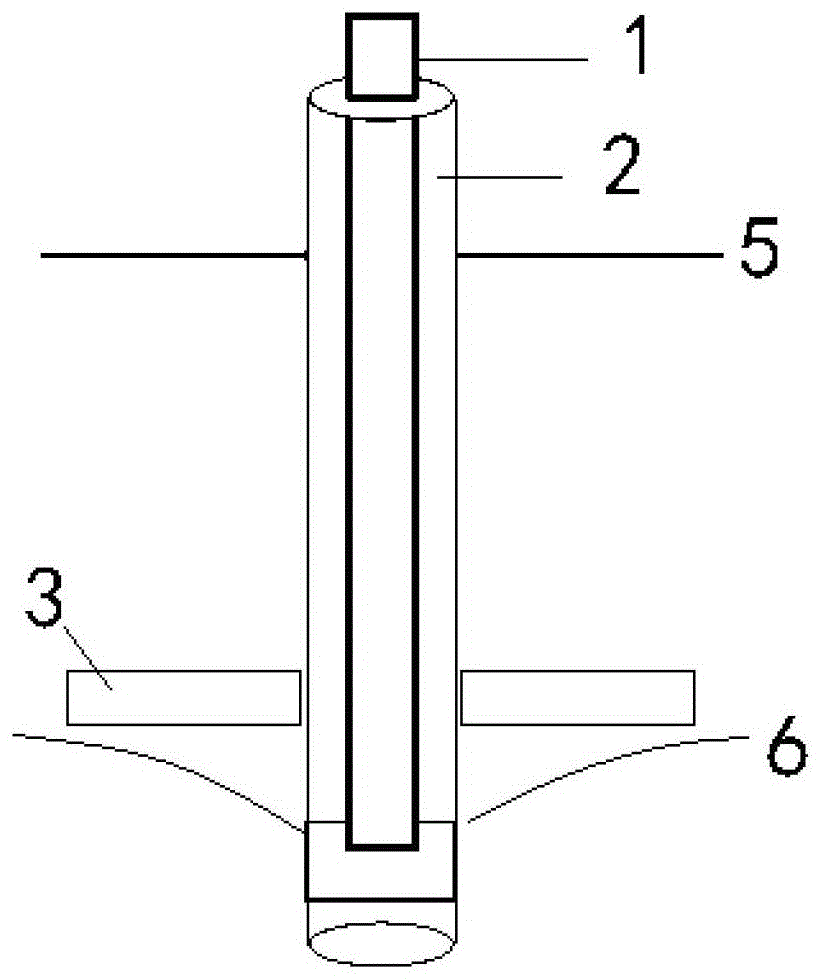

[0021] Embodiment 2: as figure 2 As shown, a coalbed methane well drainage method,

[0022] Control the braking liquid level at the second control point, which is below the bottom boundary of coal seam section 3. At this time, the liquid column in wellbore 2 has no suppressive effect on the coal seam, and the coal seam is pure gas phase flow, and a large amount of gas can be produced; avoid slow liquid level drop Due to the long-term gas-liquid two-phase flow state in the coal seam, neither coal seam water nor coal seam gas can be produced smoothly, the area of the pressure drop funnel is small, and the gas production is low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com