Low temperature double casing spherical storage tank with combination support mechanism

A technology for spherical storage tanks and support mechanisms, which is applied to fixed-capacity gas storage tanks, mechanical equipment, gas/liquid distribution and storage, etc., which can solve the difficulties of welding, the reduction of the safe operation coefficient of spherical storage tanks, and the unreliable welding quality, etc. Solve the problem, achieve the effect of convenient welding, improve the safety operation factor, and support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

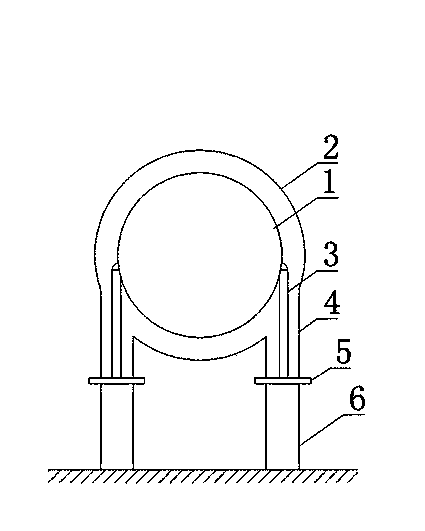

[0008] Such as figure 1 As shown, the present invention includes a low-temperature double-shell spherical storage tank. The low-temperature double-shell spherical storage tank is mainly composed of an inner tank body 1, an outer layer tank body 2 and a bracket, and the outer layer tank body 2 is set on the inner layer tank body 1. A layer of heat insulating material is provided between the inner tank body 1 and the outer tank body 2, and the bracket is a combined support mechanism, which consists of a set of A upper legs 3, a set of B upper legs 4, a set of bases 5 and A group of lower outriggers 6, a group of A upper legs 3 installed on the inner tank body 1, and evenly distributed on the outer surface of the inner tank body 1 in a ring shape, a group of B upper legs 4 installed on the outer tank body 2, and evenly distributed on the outer surface of the outer tank body 2 in a ring shape, a group of B upper legs 4 are hollow tubes, a group of A upper legs 3 are respectively l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com