Touch substrate and display device

A substrate and touch technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of reducing common electrode resistance, uneven distribution of via holes, uneven screen display, etc., to achieve display good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

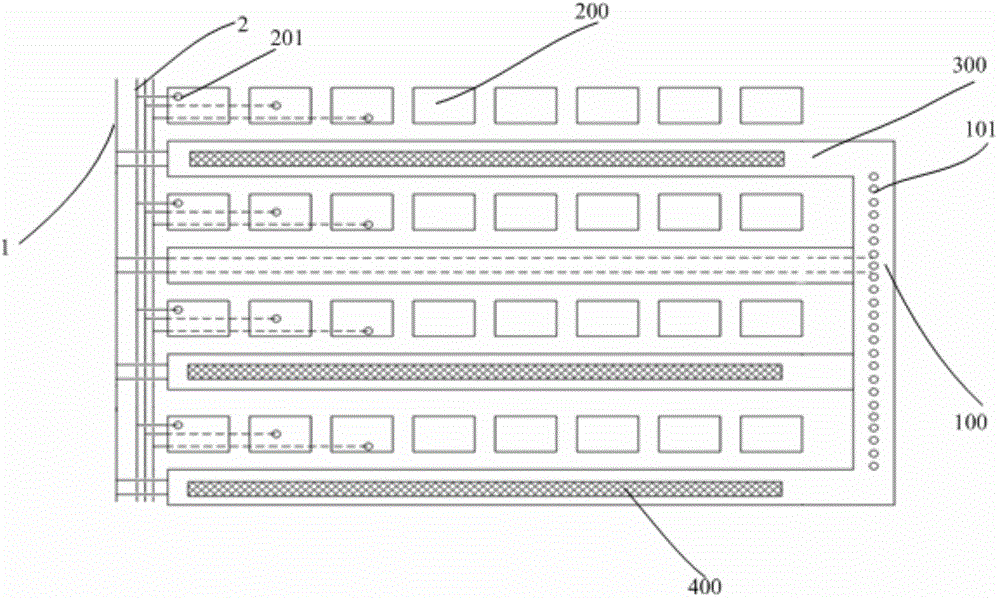

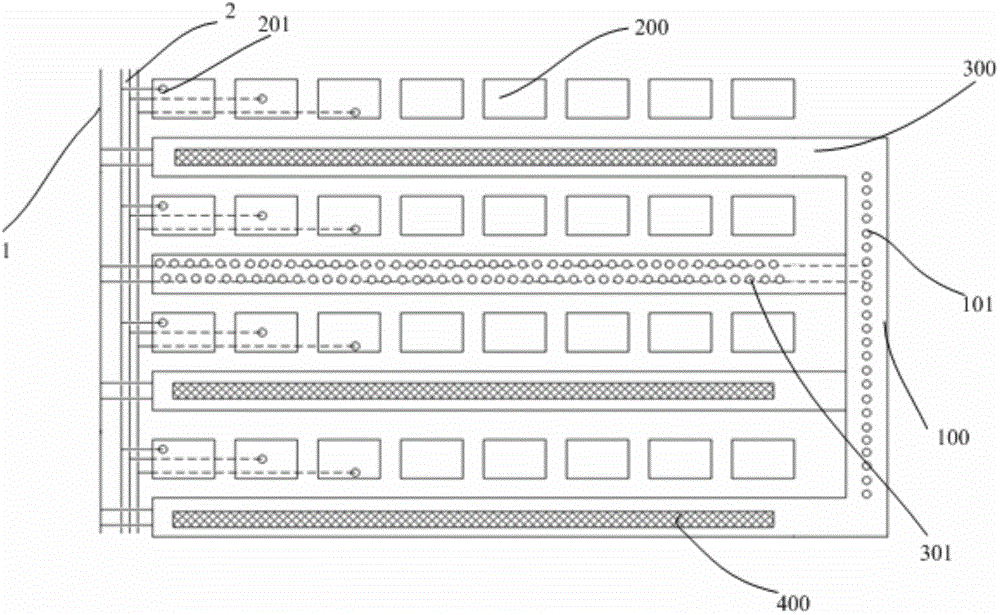

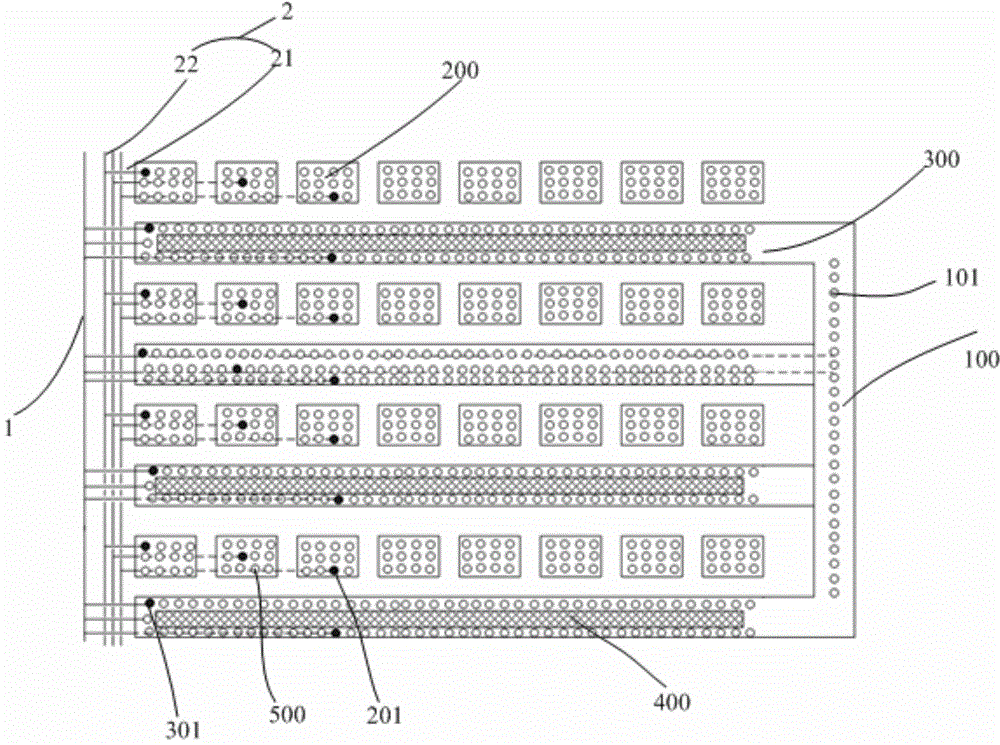

[0027] Such as image 3 As shown, this embodiment provides a touch control substrate, which includes a substrate, an insulating layer disposed on the substrate, a common electrode layer, and a common electrode signal line 1 and a driving electrode signal line 2 disposed on the same layer, wherein the The common electrode 300 layer includes a plurality of driving electrodes, a plurality of common electrodes 300, and a common electrode connection bar 100 connecting each common electrode 300, and each of the driving electrodes includes a plurality of mutually insulated driving sub-electrodes 200 (such as image 3 The driving sub-electrodes in the same column form a driving electrode), the common electrode connection bar 100 is connected to the common electrode signal line 1 through a plurality of first via holes 101 penetrating through the insulating layer, and the driving sub-electrode 200 The driving electrode signal line 2 is connected to the driving electrode signal line 2 th...

Embodiment 2

[0039] This embodiment provides a display device, which includes the touch substrate in Embodiment 1. The display device may be any product or component with a display function such as a mobile phone, a tablet computer, a television, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0040] The display device of this embodiment has the touch substrate in Embodiment 1, so its display effect is better.

[0041] Certainly, the display device of this embodiment may also include other conventional structures, such as a power supply unit, a display driving unit, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com