Exhaust system of internal combustion engine

An exhaust system, internal combustion engine technology, applied in the direction of internal combustion piston engine, charging system, combustion engine, etc., can solve the problems of insufficient meshing, the power of the electric motor is not effectively transmitted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

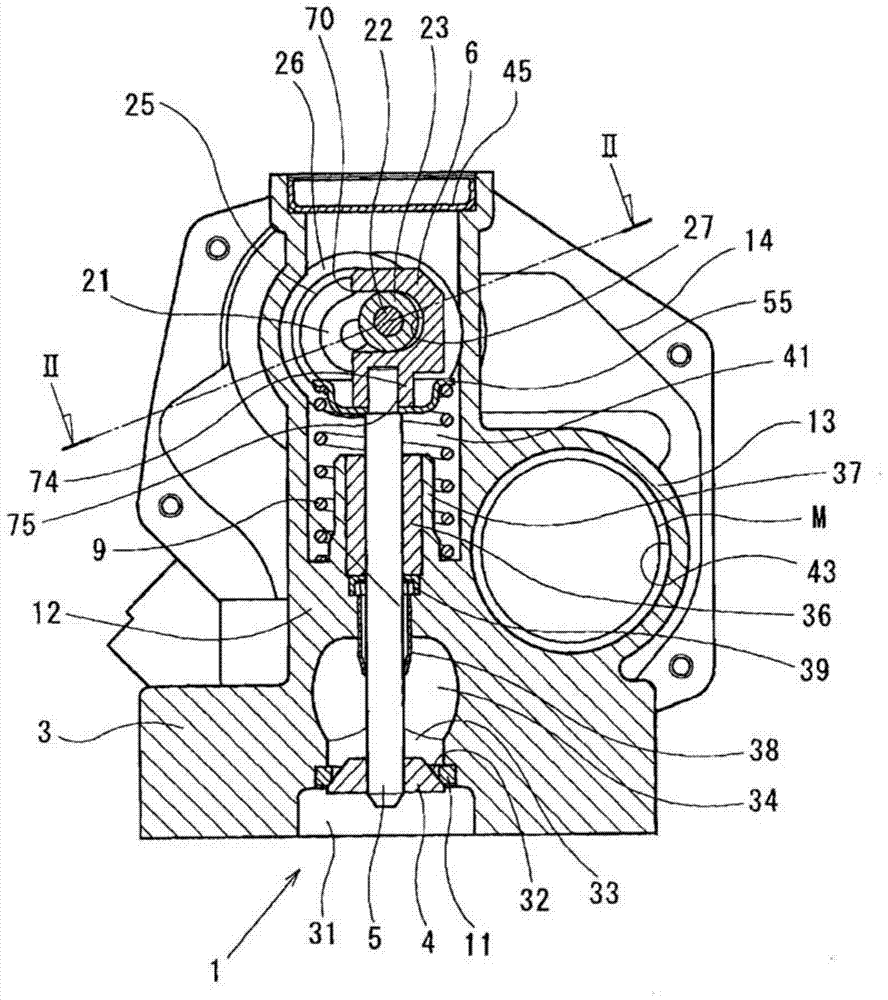

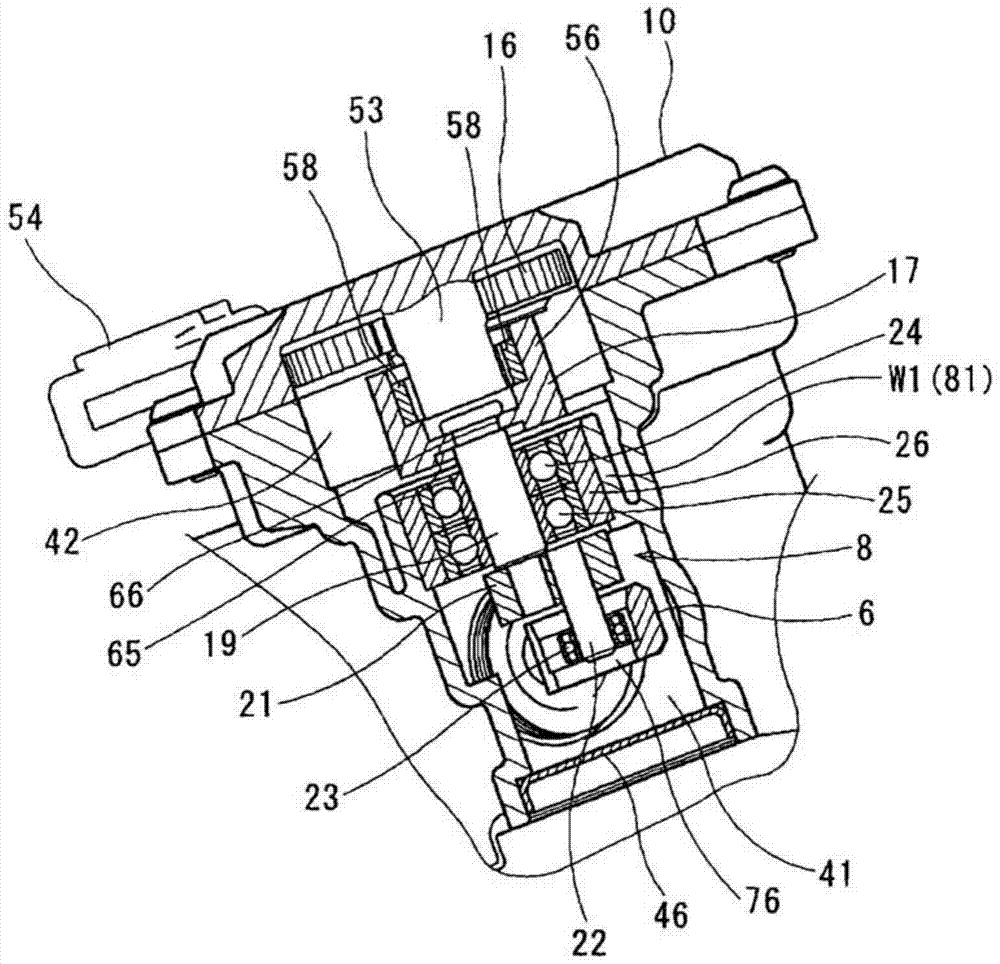

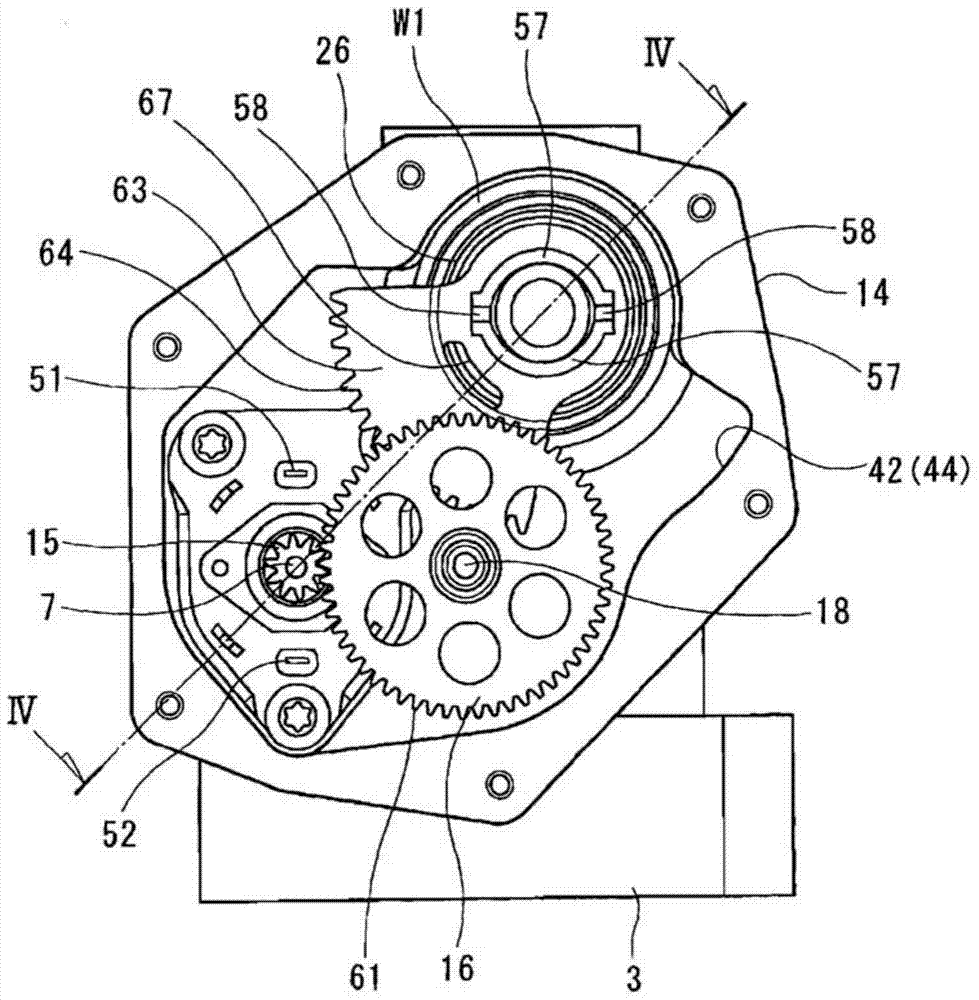

[0027] The configuration of the exhaust system for an internal combustion engine of the first embodiment will be described below. Figures 1 to 11 The EGR control valve of the first embodiment is shown, and the control valve is used in an exhaust gas recirculation system (EGR system) of an engine to which the present invention is applied.

[0028] The exhaust system of the engine of this embodiment includes an exhaust gas recirculation system (hereinafter referred to as EGR system) for transferring exhaust gas (hereinafter referred to as EGR gas) from an internal combustion engine (multi-cylinder diesel engine: hereinafter referred to as The exhaust duct of the engine recirculates (flows back) into the intake duct. The EGR system includes an EGR gas pipe for returning EGR gas from an exhaust manifold or an exhaust passage in an exhaust pipe to an intake manifold or an intake passage in an intake pipe. An EGR gas flow passage through which EGR gas flows from the exhaust passag...

no. 2 example )

[0106] The configuration of the EGR control valve of the second embodiment will be described below. Figures 12 to 15 An EGR control valve of a second embodiment is shown, which is used in an exhaust gas recirculation system (EGR system) of an engine to which the present invention is applied. The same reference numerals as those of the first embodiment denote the same or corresponding configurations or functions, and explanations thereof will be omitted.

[0107] Similar to the first embodiment, the link mechanism of the actuator 2 of the present embodiment includes a yoke 6 , an output rod 21 , a pivot pin 22 and a follower 23 . Upon receiving the rotational power of the motor M from the pivot pin 22 through the follower 23, the yoke 6 reciprocates in the axial direction of the valve stem 5, and the fitting portion 74 is press-fitted to the end of the valve stem 5 in the axial direction thereof. Proximal part (input part). Therefore, the yoke 6 is connected to the EGR valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com