Heat-insulation structure on outer side of drying tunnel

A drying tunnel and heat insulation layer technology, applied in drying, lighting and heating equipment, drying solid materials, etc., can solve the problems of reducing the service life of the drying tunnel, affecting the safety of equipment, and high surface temperature, so as to achieve the purpose of increasing the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

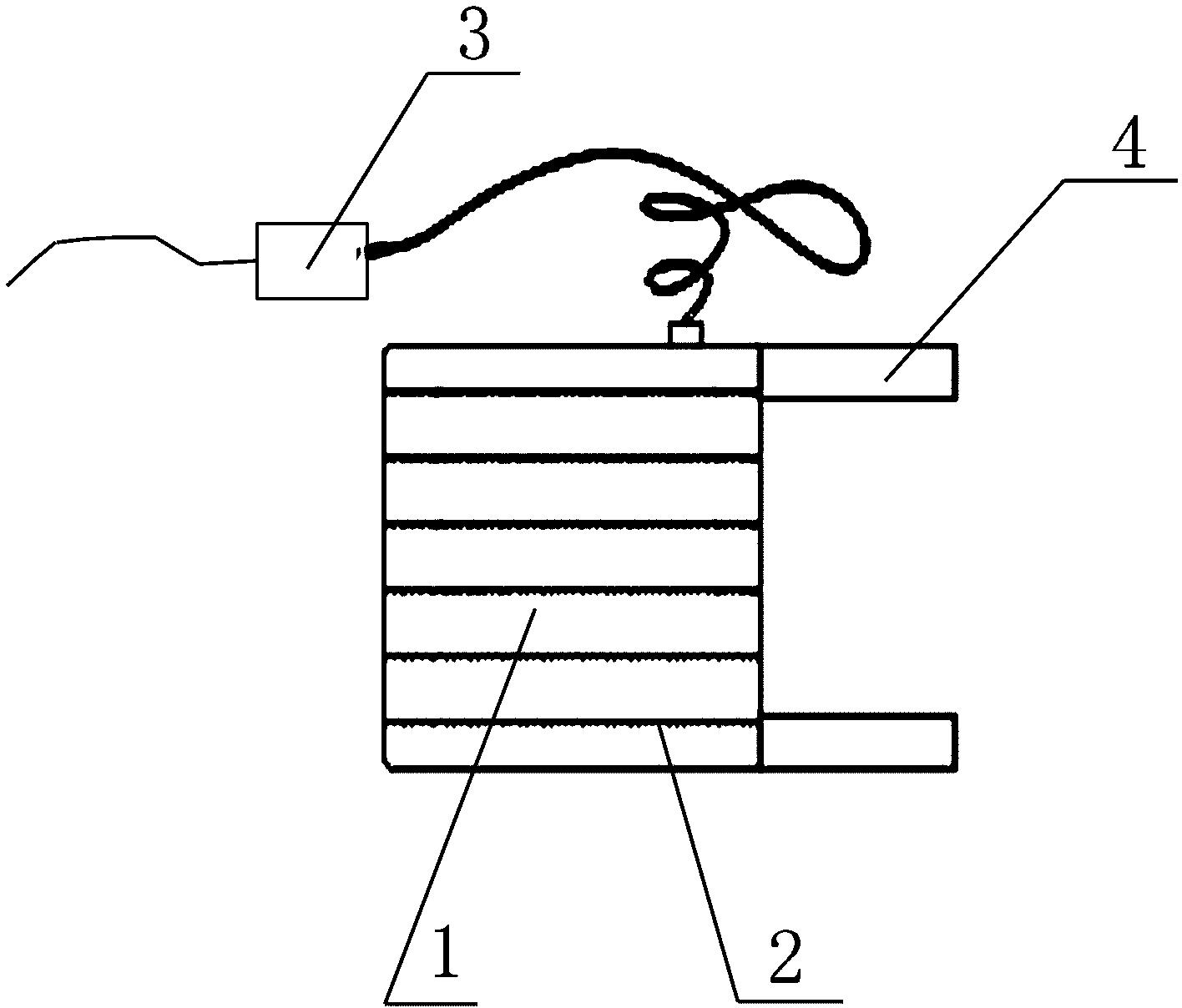

[0008] exist figure 1 Among them, the present invention provides a thermal insulation structure outside the drying tunnel, which includes an outer thermal insulation board 1 and an inner thermal insulation layer 2, the inner thermal insulation layer 2 is arranged on the outer surface of the drying tunnel 3, and one side of the inner thermal insulation layer 2 Connected with the outer surface of the drying tunnel 3, the outer heat insulation board 1 is located on the inner heat insulation layer 2, and the other side of the inner heat insulation layer 2 is connected with the outer heat insulation board 1, between the outer heat insulation board 1 and the inner heat insulation layer 2 A partition layer 4 is arranged in between, and the partition layer 4 is set to be Bakelite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com