Controller and control method for single-input and single-output non-self-balancing production process

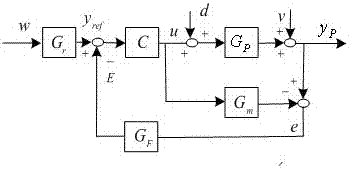

A single-input, single-output, production process technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of many controller adjustment parameters, difficulty in analyzing the stability of the control system, and difficulty in modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

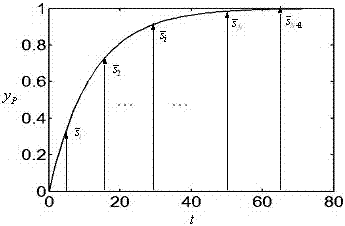

[0168] (1) According to the process characteristics, determine the system model parameter N=80 and the sampling time T s = 1s.

[0169] (2) Select the appropriate fitting point H=24, a=1, closed-loop response time T ref =10s to verify the following formula

[0170]

[0171] Whether it is true, if not, re-select the appropriate fitting point H. If the controlled object is a time-delay object, the selected fitting point H should be greater than the lag time.

[0172] (3) seeking The optimal solution of , let H 1 =H 2 = H, then y ref (k+H)=y m (k+H)+E(k+H), get the current moment control law

[0173]

[0174] And apply the control input at the current moment to the object.

[0175] (4) k→k+1, repeat steps 2-3.

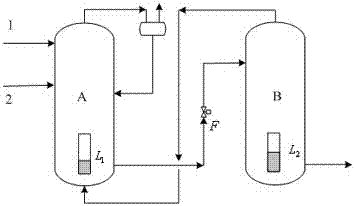

[0176] In actual operation, the operator hopes that the liquid level of column B is controlled at 60% of the total column liquid level and the fluctuation is as small as possible, and the liquid level of column B is controlled by the invented method such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com