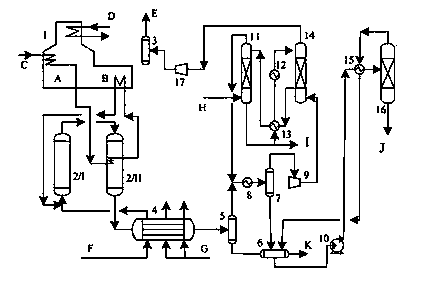

Prediction function control method during ethylbenzene dehydrogenation production process

A technology of predictive function control and production process, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve problems such as difficult to guarantee the stability of the control system and non-optimal operation of the system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

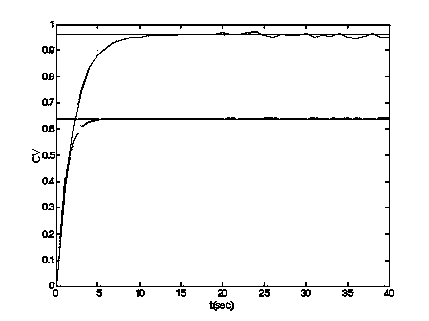

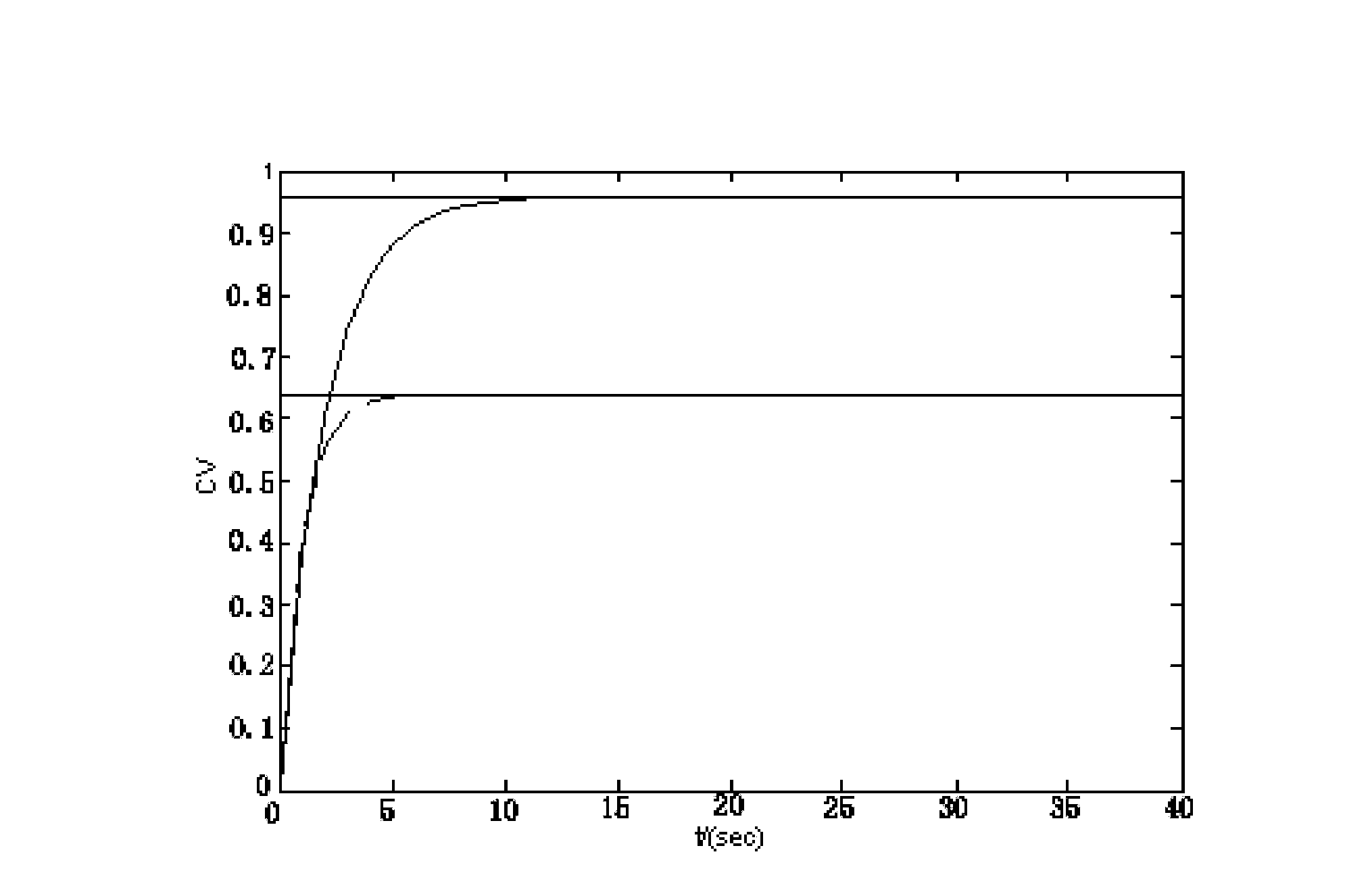

[0076] (1) According to the process characteristics, determine the system model parameters and take two basis functions u 1B1 (t)=u 2B1 (t)=e -t / Ts , u 1B2 (t) = μ 2B2 (t)=1-e -t / Ts .

[0077] (2) Prediction time domain Sampling time T s =1s, T ref =[1 2] T s.

[0078] (3) Find MIN the optimal solution of present moment control law

[0079] U(k)=u B (0)μ(k)

[0080] in

[0081] μ ( k ) = ( Y ‾ T T ‾ ) - 1 Y ‾ T [ Y R ( k ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com