Liquid distribution mechanism

A liquid dosing and moving mechanism technology, applied in mixers, dissolving, instruments, etc., can solve problems such as troublesome operation, time-consuming and labor-intensive operations, and inability to realize liquid dosing automation, achieving fast response and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

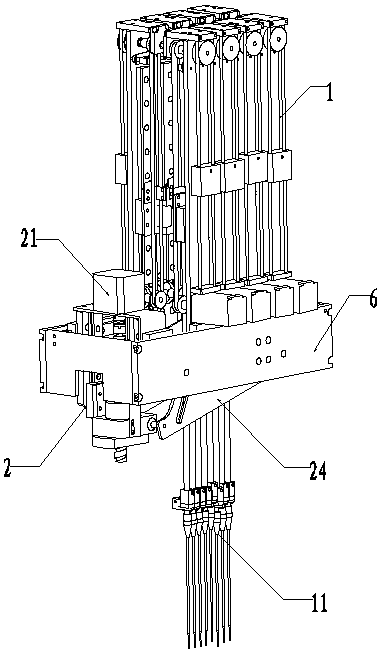

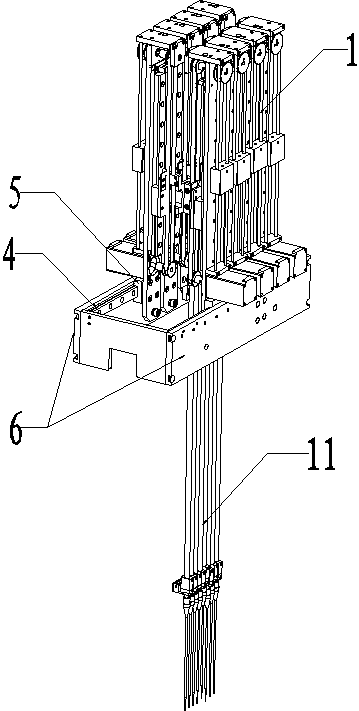

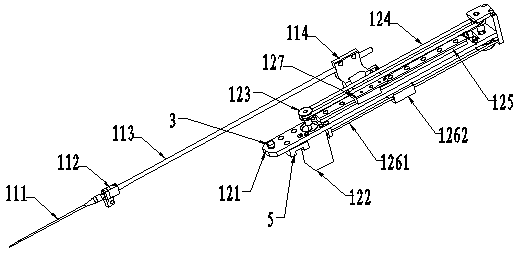

[0026] Such as Figure 1-7 As shown, a liquid dispensing mechanism includes eight liquid taking mechanisms 1, each group of four is divided into two groups, and the liquid taking mechanism 1 includes: a liquid dispensing needle 11 for extracting liquid; a moving mechanism 12 connected to the liquid dispensing The needle 11 is used to control the liquid dispensing needle 11 to move up and down; the liquid dispensing mechanism also includes: a guide mechanism 2, connected to the moving mechanism 12, used to control the lateral distance of the liquid dispensing needle 11, the guide mechanism 2 includes a driving device and a guide plate 24, The drive device drives the connecting guide plate 24 .

[0027] The moving mechanism 12 includes a support plate 121 and a first motor 122 , a synchronous wheel 123 , a synchronous belt 124 and a first guide rail 125 arranged on the front of the support plate. The first motor 122 drives the liquid dispensing needle 11 to move up and down alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com