High elastic die cushion type composite dam

A technology of composite dams and mold pads, applied in the direction of dams, barrages, weirs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

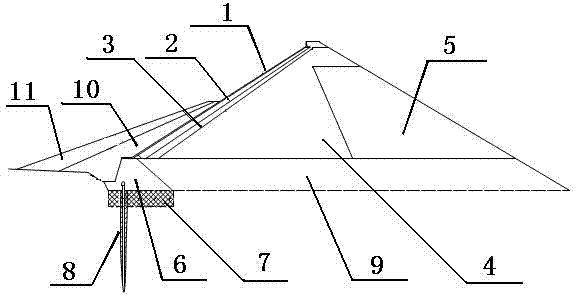

[0024] In order to overcome the technical feasibility problems of the 300m super high face rockfill dam in the prior art, such as deformation, face deflection and stress, this embodiment provides a figure 1 The high elastic modulus pedestal composite dam shown includes a concrete panel 1, a cushion area 2, a transition area 3, an upstream main rockfill area 4 and a downstream secondary rockfill area 5, which are sequentially arranged from upstream to downstream. A high-toe wall area 6 is provided at the bottom of the panel 1, the cushion area 2, and the transition area 3, and a low compression area 9 is provided at the bottom of the upstream main rockfill area 4 and the downstream secondary rockfill area 5, and the low compression area 9 is placed downstream of the high toe wall area 6 and below the top elevation of the high toe wall area 6 .

[0025] Among them, the high toe wall area 6 is designed according to the gravity dam, and the design standard complies with the releva...

Embodiment 2

[0029] On the basis of Example 1, in order to protect the concrete panel 1 and the high toe wall area 6, the upstream side of the concrete panel 1 and the high toe wall area 6 is sequentially provided with a weight area 11 and a bedding from upstream to downstream area 10; the bottom elevation of the ballast area 11 and the bedding area 10 is higher than the bottom of the low compression area 9 by more than 10m; the thickness of the bedding area 10 above the upstream end of the top of the high toe wall area 6 is not less than 10m, and meets the bedding requirements. Allowable slope requirements for Zone 10.

[0030] The upstream side slope ratio of the high toe wall area 6 is 1:t, and the value range of t is 0-0.2, the partition slope ratio between the downstream side of the high toe wall area 6 and the low compression area 9 is 1:S, and S is not less than 0.5 and is determined according to actual engineering. The high toe wall area 6 and the low compression area 9 have the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com