A tailings processing and filling method

A technology of tailings and ore slurry, which is applied in the direction of filling, mining equipment, earth square drilling and mining, etc., can solve the problems of slow hardening speed of filling body, reduction of filling body strength, large construction volume, etc., and achieve flexible and adjustable processing ratio and save Broken costs, the effect of solving source problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

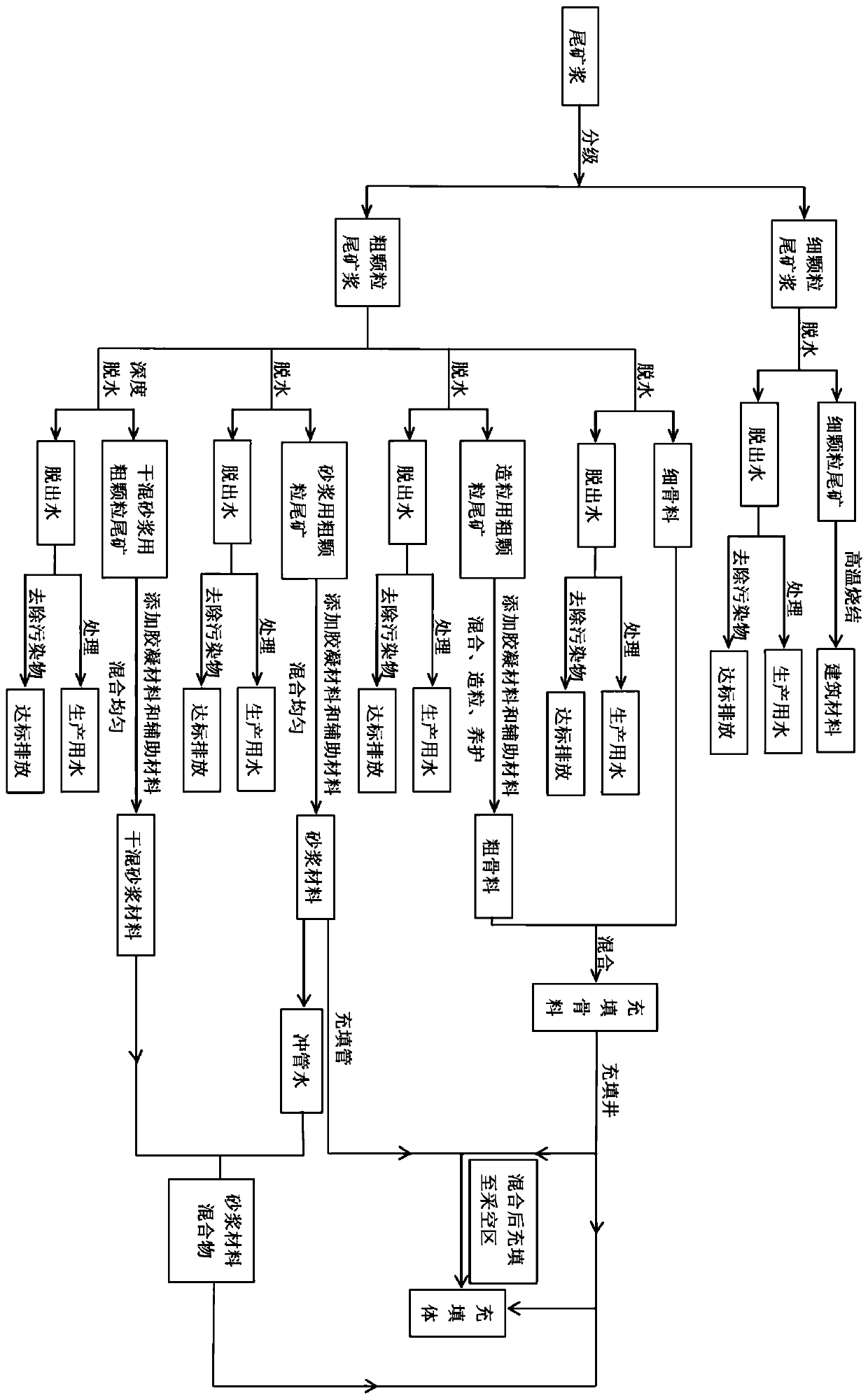

[0076] A tailings processing and filling method, the process flow chart is as follows figure 1 shown, including the following steps:

[0077] Step 1: Grading

[0078] The tailings slurry is classified by a cyclone, and the underflow tailings slurry of the cyclone is further classified by a high-frequency vibrating screen. The coarse tailings slurry is on the screen, and the fine tailings slurry is obtained by mixing the slurry under the screen and the overflow of the cyclone. The solid mass in fine particle tailings slurry after classification accounts for 15% of the total solid mass of the original tailings slurry;

[0079] Step 2: Dehydration

[0080] The dehydration of the graded tailings is specifically divided into:

[0081] (1) Dewatering the fine particle tailings slurry using a plate and frame filter press to obtain fine particle tailings, the moisture content of the fine particle tailings is 15%;

[0082] (2) After dehydrating the 10% coarse particle tailings slur...

Embodiment 2

[0096] A tailings processing and filling method, the process flow chart is as follows figure 1 shown, including the following steps:

[0097] Step 1: Grading

[0098] Use a cyclone to classify the tailings slurry. The underflow of the cyclone obtains coarse tailings slurry, and the overflow of the cyclone obtains fine particle tailings slurry. After classification, the solid mass in the fine particle tailings slurry accounts for 10% of the total solid mass of the original tailings slurry;

[0099] Step 2: Dehydration

[0100] The dehydration of the graded tailings is specifically divided into:

[0101] (1) Dewatering the fine particle tailings slurry using a belt filter press to obtain fine particle tailings, the moisture content of the fine particle tailings is 15%;

[0102] (2) Dewatering the coarse tailings slurry using a box-type filter press to obtain coarse tailings, the moisture content of the coarse tailings is 22%;

Embodiment 3

[0117] A tailings processing and filling method, the process flow chart is as follows figure 1 shown, including the following steps:

[0118] Step 1: Grading

[0119] Use a cyclone to classify the tailings slurry. The underflow of the cyclone obtains coarse tailings slurry, and the overflow of the cyclone obtains fine particle tailings slurry. After classification, the solid mass in the fine particle tailings slurry accounts for 15% of the total solid mass of the original tailings slurry;

[0120] Step 2: Dehydration

[0121] The dehydration of the graded tailings is specifically divided into:

[0122] (1) Obtain fine particle tailings after using a diaphragm filter press to dehydrate the fine particle tailings slurry, and the moisture content of the fine particle tailings is 10%;

[0123] (2) Dehydrating the coarse tailings slurry using a plate and frame filter press to obtain coarse tailings, the moisture content of the coarse tailings is 20%;

[0124] a) Air-dry the 15%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com